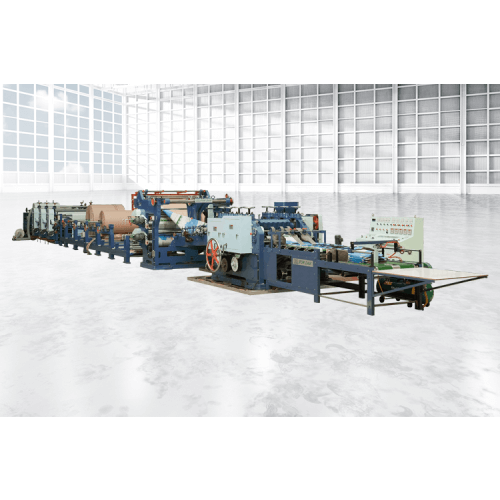

Classification : PP/HDPE Woven Bag Making Equipment

Country: Taiwan

Phone: 886-5-2215139 /886-5-2215149

Fax: 886-5-2219259

Contact Person: Ms. Lee

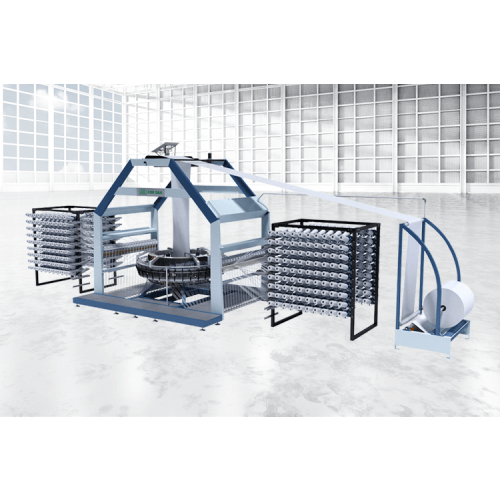

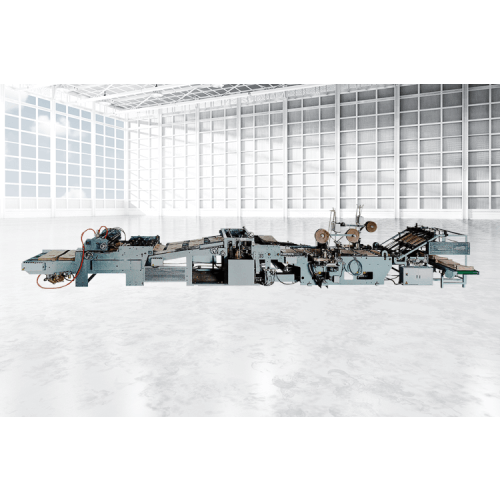

FD-6B/850 (S) are applied for weaving into tubular fabric from flat yarn spindles. It is suitable to produce variety of fabric sizs for packaging application like fertilizer, animal feed, seed, chemical, cement etc.

Designed to weave fabric from 350 to 850 mm tubular fabric, the6 Shuttles Circular Loom Machine FD-6B/850(S) is an advanced design with take-up servo control and human machine interface.

- Available working width 350~850 mm which is ideal for standard woven sack size.

- The cloth width can be determined simply by changing the gauge ring and adjusting the round holder & cloth spreading system.

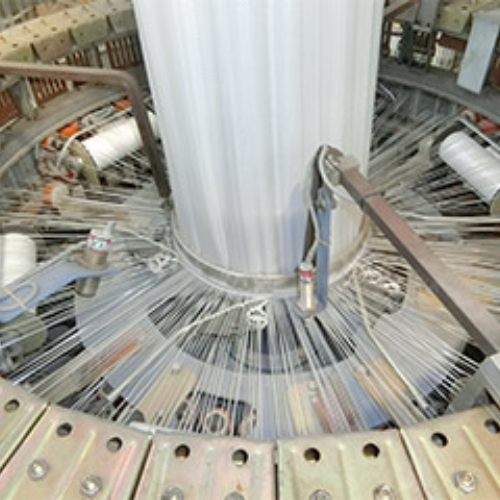

- Warp In-Feed System includes Load Cell and Motor regulates the warp tension on inlet roller to maintain uniform tension.

- Weft Breaking Detection Sensor monitors the continuous weft tape supply.

- The machine is designed with warp tension regulation system to allow even warp insertion.

- The mass of the moving parts has been reduced to a minimum to ensure high output capacity as well as long working life and reduced spare parts consumption.

- Sensor detection device on machine can stop machine automatically for weft broken and no-weft fault. The result is the production of beautiful and even fabric.

- Machine controller is applied for setting and adjusting of various machine parameter. Such as cumulative production, machine speed, shift selction-A,B,C & D, weft density, efficience, warp tension, roll length for changing of fabic roll…etc.

- Consisting of Inch Button, Stop Button, Start Button, which are easily accessible to the operating personneal from every point around the machine.

- The desired weft density can be programmed and fed in the machine controller, which controls ultimately speed of take-up rollers.

Touch Panel

Weft Finished & Breaking Detecting Sensor

Auto. Tension Controller

Middle cutting device

| Model |

FD-6B/850 (S)

|

|---|---|

| No. of Shuttle | 6 Shuttles |

| Layflat Width | 350~850 mm |

| Mesh Control | Servo Control |

| Mechanism | Belt |

| Shuttle Speed | 130~150 RPM |

| No. of Warp | 720 pcs |

Included Device

- Main Inverter: 1 set

- Auto. Tension Controller: 1 set

- Weft Finished Detecting Sensor: 1 set

- Weft Breaking Detecting Sensor: 1 set

- Warp In-Feeding System: 1 set

- Operation Touch Panel: 1 set

- Servo Motor and Servo Driver: 1 set