Twin Screw Extruders

Twin screw extruders feature two co-rotating or counter-rotating screws, offering superior shearing, mixing, and dispersing capabilities. They are ideal for multi-component formulations, high-filler compounds, and reactive extrusion processes. Common applications include compounding, masterbatch, biodegradable plastics, and engineering polymers.

PRM-Taiwan offers a wide range of twin screw extrusion solutions for compounding, pelletizing, lab-scale testing, and high-volume production, tailored to meet complex formulation and performance demands.

SINO-ALLOY MACHINERY INC.

SINO-ALLOY MACHINERY INC. manufactures a full line of Co-Rotating Twin Screw Extruders. Typical applications for our product line include Polymer Alloying, Reinforcement, Reaction, Degassing, Master Batch Manufacture, and Filling. We also offer an extensive line of Auxiliary Equipment to complement our extruders, as well as Turn-Key Compounding Technology in conjunction with our affiliate POLYALLOY INC. Sino-Alloy's family of PSM co-rotating twin-screw extruders have been developed for use anywhere from laboratories and institutions to large-volume production facilities. Each new model of PSM extruder arguably leads the plastic compounding industry with the integration of experience and technology. Breakthrough accomplishments at Sino-Alloy are continually changing the nature of compounding. All PSM series machines are production-tested through runs at POLYALLOY INC. prior to new product announcements or market availability. Sino-Alloy's team of skilled and educated personnel closely monitors hardware reliability and integrated software performance to detect faults and opportunities for improvement. Our experience enables us to continuously improve the efficiency and quality of our machines while meeting and exceeding the standards expected by our customers.

KNEADER MACHINERY CO., LTD.

Kneader Machinery Co., Ltd. (KMC) was established in 1981 and is the first manufacturer of Dispersion Kneader in Taiwan. Accumulated with closed to 40 years experience, incessant research and development and validated with the appraisals of more than 4,000 sets , KMC is almost one of the largest builder of Dispersion Kneader, and KMC is becoming the nickname of kneader in the market. Presently, the total area of production bases across Taiwan Strait is more than 66116㎡ and is sufficient for meeting expanding market now. In addition, following the green energy policy of the Government, we built solar energy installation to our factory building to fulfill our obligation as corporate citizen. KMC has headquarters located in Tainan,Taiwan to consolidate and control worldwide business. In addition to increase new factory facilities in Taiwan and in China, we also set up our business points in USA and Vietnam to offer the best and fastest services to customers. KMC has also commenced sustainable operation plan for the next 40 years. We have started to inject new team of talents, so that the heritage of the company may be passed down and the professional skills may be carried on and improved all the time that our customer will have lasting cooperating supplier with excellent services. Turn Key Project In order to provide customers with complete product line and services, KMC is working to integrated flow design and is offering turnkey proposal basis unique needs of individual customer. WE have also set up laboratories in Taiwan headquarters as well as KMC USA (set up in 1997). The data from laboratories, feedback of customers and 40 years experience, aided with computer aided program, we developed tailor made machine and production flow for customers and offer them with individual specific solution. Among those , KD pelletizing equipment, KD sheet making / strip extruding equipment are most welcome. In addition to meet the QA System latest version of ISO 9001 in spirit and in physical requirements, the Company continues in correction and prevention as well as risk assessment and is pursuing own long time target, and the safety of equipment and products are all meeting CE standard. The Company is capable in providing excellent equipment for rubber and plastic materials, highly customized and fitting to market demand. The systems we have developed are integral one through system, from Raw Material Filling→Conveying (Powder, Granular, Block or liquid)→Automatic Metering of Small Volume or Large→Laboratory development or Mass Production Kneading Mixing→Powder Dust Filtering→Kneading to Sheet or Grain→Sheet Cutting or Pelletizing→Air Cool, Air Conditioned Cool and Water Cool Dehydration→Completed Rubber / or Plastic Raw Material Preparation. The Company is marching to Industry 4.0.

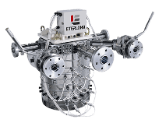

TWIN SCREW INDUSTRIAL CO., LTD.

TWIN SCREW is founded in 1988, the first company engaged in the manufacture of PVC parallel counter-rotating Twin Screw Extruder in Taiwan . The past decade has seen this company install more than 600 Twin Screw Extruders for complete production lines including PVC pipe production, various types of Profile, Decorative Profile, Pelletizer, Granulating units and for Recycling. Excellent production quality control, perfect after-sales service etc, experience is the hallmark of “TWISIC”

CYKF MACHINERY CO., LTD.

CYKF is the brand name of CYKF MACHINERY CO., LTD. “CYKF” means sincerity and quality, which represents our sincerity that makes customers successful, and our products are as strong as a jade. With our skills and proficiency in plastic extrusion combined with our considerate service, we are able to customize the products that meet customers’ requirements and expectations. The Enterprise Specialized in Plastic Extruder CYKF established in 1999, devoted ourselves to developing diverse types of precision plastic extruder. Twenty years ago, we already had the capability to build equipment controlled by industrial computer, and such achievement made us stand out from the local competitors. With our continuous efforts, coupled with high-quality machines, professional extrusion experiences, and instant service, these excellent corporate images have successfully earned trusts and prestige from customers worldwide. Along with the technological upgrades for industry in 2005, we have been committed ourselves to researching, developing, designing, integrating, and manufacturing the automatic system of extrusion lines. All these efforts have brought the superiorities of our products that are sustainability, simplify the manipulation, saving human resources, guarantee the safety and the quality as well as reduce the productive costs efficiently. Now we have accumulated plentiful performances and experiences in building automatic pelletizing systems for PVC, compounding, and plastic recycling. CYKF, carries the enthusiasm and keeps manufacturing reliable and durable equipment for customers as always. Advantage Advantages in Technology Our solid foundation in extrusion technology enables us to design tailor-made solutions for customers. CYKF has abundant skills in plastic compounding and dedicated to manufacturing the equipment and components of plastic extrusion systems for PVC, compounding, and plastic recycling. The team of CYKF specializes in R&D of extrusion technology to cater for multiple plastic characteristics. We are capable of designing the high efficiency and competitive extrusion system for every customer to help them maximize the benefits. In addition, our products are not only as firm as steels but also ensure high efficiency and quality performances. To enhance our production capability to the first class, we pay attention to every detail of manufacturing processes. The pelletizing extrusion lines made by CYKF had been sold to many countries and keeps extending rapidly. In order to become the acknowledged excellent manufacturer in the world, we never stop implementing the philosophy of integrity, precision, and quality. We believe that by developing our own brand can we manifest the spirits and values of CYKF. Responsibility in Product Quality Every machine made by CYKF carries the responsibility of long-term operation. In order to build outstanding plastic extruders and respond to customers’ multiple demands, we strengthen our abilities on customization and system integration to face challenges from the state-of-the-art technology in the industry. Our customized services embody the greatest values of CYKF, which are safety, convenience, efficiency, and quality. The Pursuit of Perfection, Local Operation, Global Vision CYKF pursues the quality rigorously to ensure every tiny but important detail in the production processes. CYKF starts with a small plant and gradually growing into a respectable enterprise now. We are not only the best choice for domestic customers but also have the strength to provide services for global customers. Our achievements assist the extrusion industry of Taiwan stands on top place, moreover, we continue making ourselves glowing in the global market.

CONTINENT MACHINERY INDUSTRIES CO.,LTD.

Continent Machinery was established in 1972. Company locates at Tainan, Taiwan with 16,500 m2 of factory area. The space allowed assembly and production of large machinery in Continent Machinery. R & D department and QC department is the core of Continent Machinery to ensure the product have good design and quality to satisfy our customers. Continent has more than 50 years experience in manufacturing varieties of extruder machine; Co-Rotating Twin Screw Extruder, PVC twin / single screw extruder, High output Single screw extruder, Recycle extruder, Profile extruder and sheet making machine are all our major products. Extrusion lines from Continent Machinery are highly rated by customers all over the world. Our customers spread in China, Japan, Thailand, Malaysia, South Africa, Mexico, Greece, American and most Asian.

WELL SHYANG MACHINERY CO., LTD.

The initial corp. named “San I Steel Works” and next “Hsin Wan Machinery Works” then promote to “Well Shyang Machinery Co., Ltd.” as of now (hereinafter referred to as WELLSHYNAG). The existing President – Mr. Wan-I Chang who is the tertiary runner, obtained a great social relationship and a great number of customers in Taiwan Machinery manufacturing field.