MEMS Gas Mass Flow Meter 0-1000L/min

Categories : Separators

KMF1000 series digital gas mass flow meter is made of micro- electromechanical system (MEMS) flow sensing chip, suitable for a variety of purposes of clean, relatively dry nature of the small flow gas measurement and process control, unique packaging technology makes the product to meet the different ranges of flow measurement, to ensure high sensitivity, high reliability, high stability and low cost. It is based on a MEMS flow sensing unit and a high precision digital processing and calibration circuit (MCU). The integrated Δ-Σ A/D converter and the logic circuit with internal calibration function and MCU processor together ensure the real-time effective acquisition of the sensing signal, to obtain the accurate flow signal, and the corresponding compensation algorithm processing in the internal, so there is no need to do any external calibration and compensation to ensure high-precision.

High Flow with Volume Booster(0-10bar)

Categories : Indicators and Sensors

Product Serial: 1. QKL-B1T Electronic Pressure Regulator Provides an air pilot signal to the dome of the air volume booster. By controlling pressure to the top of the diaphragm, we control pressure out of the volume booster. QKL-B1T has the feature of high resolution and fast response time, which is well suited to act as the pilot pressure. 2. Air Volume Booster Also known as the dome-loaded or pilot-operated pressure regulator. This can be a pressure reducing valve or a back pressure valve. We have many volume boosters available that can handle different pressures, medias and flow rates.

Air Pressure Ratio Regulator(0-103bar)

Categories : Indicators and Sensors

Product Serial: QKL-B1T+QKL-BPF • B1T Electronic Pressure Regulator Provides an air pilot signal to the dome of the air volume booster. By controlling pressure to the top of the diaphragm, we control pressure out of the volume booster. • Air Pressure Ratio Regulator KaoLu’s high pressure ratio regulator is mostly used in high pressure environment, in which the users are used to using mechanical air pressure regulator. Using our high pressure ratio regulator assembly, it is now possible to electronically regulate high pressure from potentially hazardous environment using control such as RS485-modbus serial communication. Using the dome-loaded method controlled by our electronic pressure regulator, the users can achieve pressure up to 3000 psig (210 bar) with resolution up to 5 psig (0.3 bar). Moreover, our high pressure ratio regulator not only works with air, the newly developed ratio regulator is compatible with different fluids such as water and high temperature steam pressure. There is a choice of single loop feedback or external sensor feedback. With single loop feedback where we ensure the dome loaded pilot air is the same, the drawback is that the output pressure from the high pressure ratio regulator is not monitored. The accuracy is typically about 2-3% with this method. In a different scenario where an external sensor was mounted to the ratio regulator or mounted remotely downstream of the high pressure ratio regulator, we can ensure high accuracy to be achieved. Please click on below link for application: Tire Curing

Double Arm Open Type Kneader

Categories : Dispersion Kneaders

The KD double-arm kneader is available with a variety of blades in different shapes as well as with number of discharging methods and mixing conditions. This KD double arm kneader has already achieved considerable renown in a wide range of industries that deal with such high and medium-viscosity materials as adhesives, agglutinates magnetic materials and chemical material mixing. Applications: Banbury Type Lade Adhesives Hot-Melt materials Sealing Materials Ceramics Magnetic compounds Silicon Rubber Sigma Type Blade Printing inks Tapes Pigments Thermosetting Resins Chemicals

Coating Dies Slot / Slit

Categories : Extrusion Dies / Dies Heads

Slot/Slit design, excellent manifold geometry design, solvent resistant alloy, super mirror grinding technique SUITABLE APPLY TO Water Base /Oil Base / Non-Solvent Type Liquid Straightness precision is made by GMA exclusive grinding technique to reduced film thickness deviation of groove width. Interchange shim for variable lip gap application. Special stainless steel resists to a full range of solvents. Work with automated controller. Manifold geometry simulation analysis technique and optimum manifold design base on customer’s material. Uniform and stable flow distribution. No coating line defect with even thickness at high speed. Professional Slot Die maintenance service by third parties is acceptable.

Twin Screw Extruder - Counter Rotating Type

Categories : Gearboxes

(1) Both Co Rotating & Counter Rotating types of TB series Twin Screw Gear Reducer are composed by Input & Output elements. Especially for output side which installed by Thrust Bearing plus with flange which could suffer high pressure to absorb the axial pressure caused by the extruders. (2) Following AGMA criterion to design gear elements which adopts low-carbon alloy steel bar materials(Normally, it is SCM420 or same level). The precision reaches AGMA 10 level after carburization heat treatment then treating gear surface grinding to make sure low noise, low abrasion and high efficiency during operation. (3) #294 Series Thrust bearing with axial self-aligning roller type & muti-row stacked tandem bearing package to have advantage of low friction heavy axial load capacity.

Twin Screw Extruder Co-Rotating Type

Categories : Gearboxes

(1) Both Co Rotating & Counter Rotating types of TB series Twin Screw Gear Reducer are composed by Input & Output elements. Especially for output side which installed by Thrust Bearing plus with flange which could suffer high pressure to absorb the axial pressure caused by the extruders. (2) Following AGMA criterion to design gear elements which adopts low-carbon alloy steel bar materials(Normally, it is SCM420 or same level). The precision reaches AGMA 10 level after carburization heat treatment then treating gear surface grinding to make sure low noise, low abrasion and high efficiency during operation. (3) #294 Series Thrust bearing with axial self-aligning roller type & muti-row stacked tandem bearing package to have advantage of low friction heavy axial load capacity.

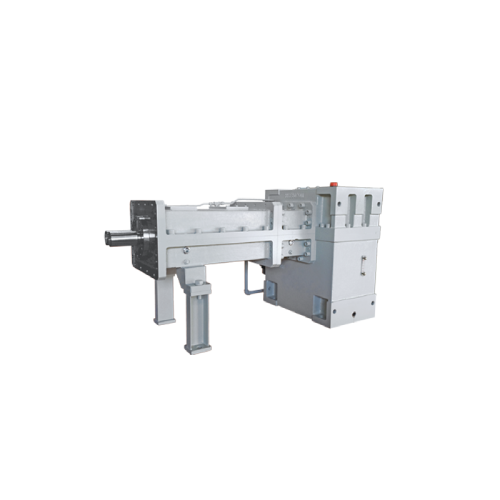

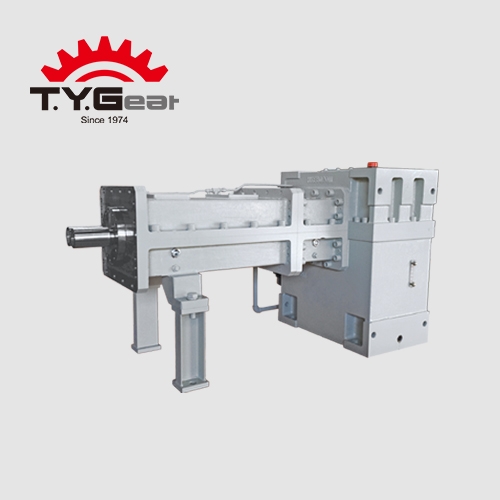

for Electrical Injection Molding Machine- TGSM Series

Categories : Gearboxes

Features: Save power & suitable for big tons of output in production High torque, High rotation speed, Less abrasion & low noise. Lubrication System: Oil Forced Type Reach AGMA 10 LEVEL & UP Gear material: SCM420 Shaft: SCM440 Stable output during injection, Power starts when the material has been delivered and stops automatically when no material is detected Motor Flange & Input Shaft customized available as per request.