85-150 ton injection molding machine product

Categories : Injection Molded Products

This 85-150 ton injection molding machine is designed for high-precision plastic product manufacturing, including automotive components, electronic parts, appliance housings, medical devices, and consumer goods. Equipped with a high-efficiency servo-driven system, it ensures stable injection pressure and precise control, delivering superior molding quality. With a high-rigidity clamping structure and an optimized hydraulic system, this machine offers durability and operational efficiency. It supports various plastic materials (PP, PE, ABS, PC, PA, etc.) and can be customized with multi-stage injection units and robotic interfaces for full automation, reducing labor costs and increasing productivity. Ideal for OEM manufacturers, plastic molding factories, and precision molding industries, this model meets modern production demands with efficiency and precision.

Insert Injection Molding

Insert Injection Molding Technology is a manufacturing process that integrates pre-placed components, such as metal inserts, electronic parts, or other materials, into a plastic injection mold. During molding, molten plastic encapsulates the insert, creating a single, durable, and high-precision component. This technology enhances product strength, reduces assembly costs, and improves reliability, making it widely used in automotive, electronics, medical devices, and consumer products. By ensuring strong adhesion between plastic and inserted components, insert injection molding enables lightweight designs, enhanced durability, and improved performance in various applications. Key Advantages: Seamless integration of metal and plastic components Higher product strength and durability Cost-efficient by reducing assembly steps Customizable for complex geometries Enhanced precision and consistency Common Applications: Automotive Parts – Armrest trim panels, dashboard components, connectors Electronic Components – Connectors, circuit boards, protective casings Medical Devices – Surgical tools, sensor housings, implantable components Consumer Goods – Power tool grips, ergonomic handles, durable casings

Horizontal Automatic Rubber & Silicone Injection Molding Machine - FCH Series

Categories : Silicone Injection Molding Machines

Natural rubber, synthetic rubber, oil-proof & heat-proof rubber and reclaimed rubber products. Automobile parts, electronic components, diving items, oil seal, soprt goods and other rubber products.

Rubber Injection Molding Machine - FCR SERIES

Categories : Rubber Injection Molding Machines

Natural rubber, synthetic rubber oil-proof & heat-proof rubber and reclaimed rubber products. Automobile parts, electronic components, diving items, oil seal and sports goods, and other rubber products.

Two Platen Injection Molding Machine NRH Series

Categories : Horizontal Injection Molding Machines

The NRH Series Two-Platen Injection Molding Machine is your ideal choice for manufacturing large and complex plastic components in various sectors, including automotive, logistics, and home appliances. With patented mechanical innovations and compact design, it delivers consistent precision, fast mold change, and long-term durability, making it the go-to solution for businesses seeking performance and efficiency in high-tonnage molding.

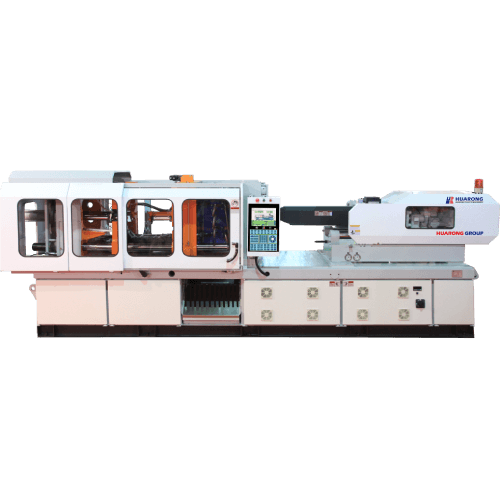

General Injection Molding Machines-HRU & HRN Series

Categories : Horizontal Injection Molding Machines

The HRU & HRN Series is Huarong’s standard general-purpose hydraulic injection molding machine. Built with a durable inward toggle system and proven core technology, it offers stable production, long service life, and a full range of CE-certified safety features. Ideal for automotive, packaging, electronics, and everyday consumer plastic components.

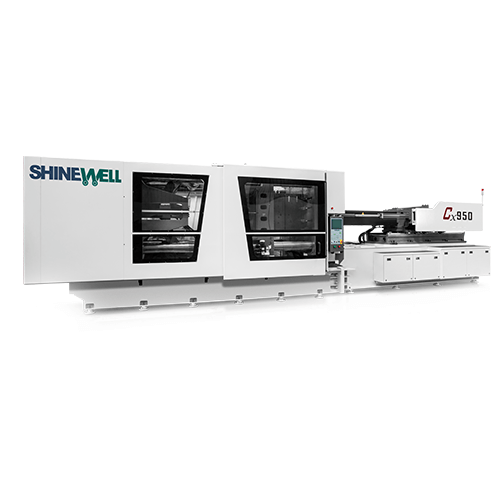

Servo Energy Saving Injection Molding Machine CX-60 – CX-1600

Categories : Horizontal Injection Molding Machines

APPLICATIONS:Packaging,Optics,Electronics,PET Preform,Closures,Cutlery,Thin Wall,Automotive

Vertical Rubber Injection Machine

Categories : Rubber Injection Molding Machines

Screw & barrel temperature controlled with kerosene preheated by built –in temperature control system; a high volume of belt-shaped rubber can be feed, essential for production of large size, high volume products like car parts or gaskets.