Compact Type Blown Film Machine - YHS

Categories : Blown Film Extruders

Compact Type Blown Film Machine - YHS

Multi Co-Extrusion High Speed Blown Film Machine - YH-2-H

Categories : Blown Film Extruders

Complete Filmblowing Lines for HDPE/LLDPE

HDPE High Speed Mono Layer Blown Film Machine

Categories : Blown Film Extruders

Application: T-shirt bags, shopping bags, garbage bags, mattress cover, laundry bags etc. Suitable material: HDPE / MDPE / HDPE+LLDPE Film layer: 1 layer Screw L/D ratio: 30:1 Direct-connection design gearbox. PID+SCR temperature controller. ABB or HITACHI inverter. Gusset device.

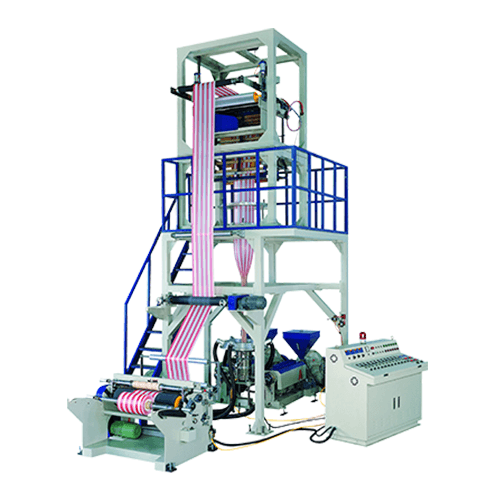

Two Color Striped High Speed Blown Film Machine - HDF-H-2

Categories : Blown Film Extruders

● Two independent extruders. ● To produce film with two colors stripes.

HEAVY-DUTY BLOWN FILM MACHINE WITH OSCILLATING HAUL-OFF UNIT

Categories : Blown Film Extruders

Film width available from 2000 ~ 4000mm, excellent for heavy-duty bags. Unique die head and air ring design to achieve stable bubble and better even thickness film and bag. Gear box uses high torque and enforced lubrication system. Automatic surface winder with uploading device. Oscillating haul-off. Blown film machine with oscillating haul-off system, built under the supervision of professional European engineers. AC inverter motor is designed for high production, quality and reliability to produce tubular film. High torque gear box with enforced lubrication system to minimize machine shutdown time. Good mixing performance of screw and barrel results in homogeneity and high output. Oscillating haul-off unit allows minimum web tension that eliminates wrinkle or bulge problem. High volume air ring is designed for ideal cooling efficiency.

HDPE Super High Speed Blown Film Machine

Categories : Blown Film Extruders

King-Plus HES Series is designed to produce HDPE plastic film, while LES series for LDPE plastic film. These machines could give you advantages with high-quality, extraordinary mixing performance and high output capacity. With precise machinery design, they could work in efficiency state to realize the achievement of saving energy. HDPE & LDPE film is commonly used to shopping bag, garbage bag, surface protection film and barrier film etc.. There are some auxiliary options as like rotary die seat, auto loader, gusset device, embossing device and auto roll change device and so on, to build a especially-suitable blown film machine for you.

PP Blown Film Machine - HFPP

Categories : Blown Film Extruders

Water cooling system makes glossier and more transparent PP film for food or garment packing.