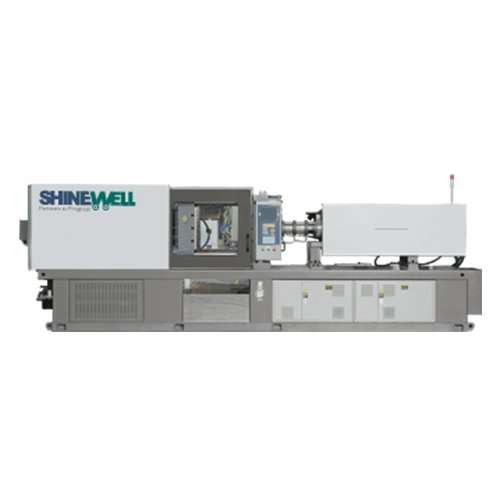

Thermosetting Injection Molding Machine 90BBE to 400BBE

Categories : Horizontal Injection Molding Machines

● EXTRA ELEMENTS FOR THERMOSET PROCESSING ● SPECIAL SCREW BARREL DESIGN FOR THERMOSET MOLDING ● THREE-STAGES HEATING COMPONENT FOR KEEPING THERMOSETS UNDER A PERFECT PLASTISIZING CONDITION

Guillotine Knife

Categories : Industrial Knives

HomeProductsInverter / Inverter Duty Motor: GFEF Series

Categories : Motors

Foot mounted Insulation class: F class Suitable for general inverter applications Basic speed adjustment Reliable operation function Energy-saving and easy-maintenance

2RT Mold-Open Tire Bladder Rubber Injection Molding Machine

Categories : Rubber Injection Molding Machines

Mold opening design The 2RT surpasses the traditional top opening mold that can be used for the double or triple molds with the design of the opening mold and pushing out the mold in the between. The opening mold can be adjusted by the software with separate opening, separate pushing out the mold in between. tyre bladder

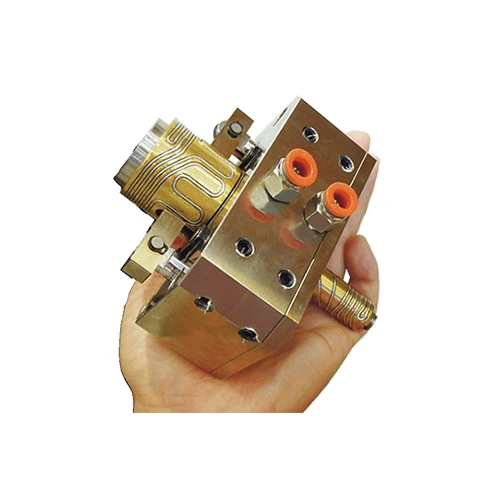

Single Valve Gate Hot Runner System

Categories : Hot Runner Systems

Dual-cylinder, powerful for gate seal. Nice gate mark. All in one, easy to install. Customize for your need.

HDPE/LDPE Blown Film Line (JC-HS Series)

Categories : Blown Film Extruders

JC-HS Series Blown Film Extrusion Line is the best choice for maximum volume and top quality output. Distinctive new screw design with option to upgrade automatic winder for high capacity output and efficiency.

PET Stretch Blow Molding Machine - TEM04M1

Categories : Automatic Blow Molding Machines

FEATURE Adopt the touch screen control system with 64K color and friendly PLC operation. Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system. The preforms are automatically arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste. Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly. The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating. Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method. With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems. Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp. The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution. Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.