Classification : T-shirt bag series

Country: Taiwan

Phone: 886-5-2217005

Fax: 886-5-2211929

Contact Person: Sammuel Chiu

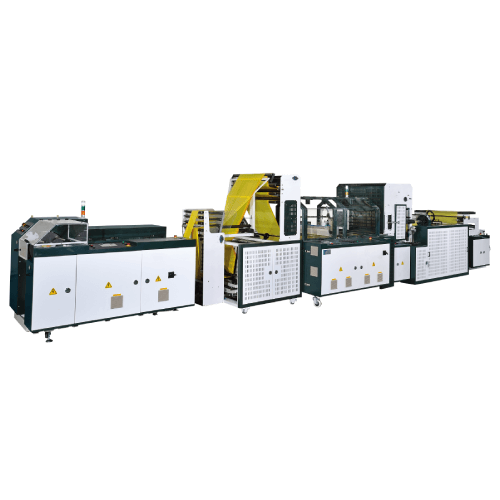

- Auto-packaging solution - Saving collection labour further by auto-packing solution. Finished piles are auto-packaged individually by printed outer bags. Customized solutions available

- High speed hot-cut system - For printed T-shirt bags. Photocell & servo registers accurate print position. High speed hot-cut system available in 200/250/300rpm systems.

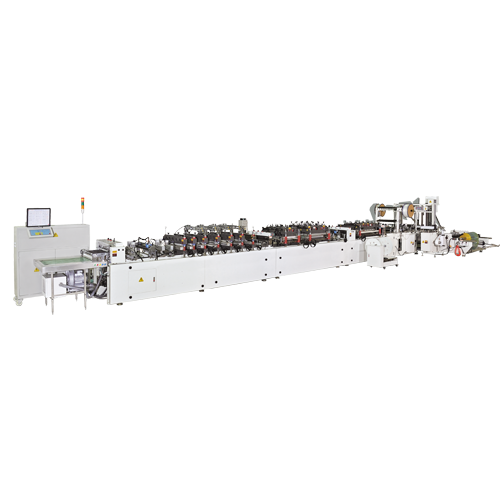

- Twin-servo system - 2 servo controlling 2 lines with printing register accurately.

- Tensionless high speed hot-cut system : Upper sealing blade & bottom heating wire makes strong and high speed sealing. Tensionless sealing avoids sealing line pull& elongation for highspeed production. Seperated upper and bottom temperature control for easy micro-adjustment.

- Gripper + pneumatic punch : When counts reached, inline gripper collect and pneumatic punch cut out waste area and removed by conveyor.

- Rocking pin block : Blocking pin base rock back and forth to avoid sealing line sticking to previous bags.

- Synchronized feeding and cutting speed : Inverter controlled feeding matching main machine speed for easy operation without manual adjustment.

- German "Sick" photocell registration : Reliable and accurate print registration and positioning

- Auxiliary air-blown outfeed : Air blown assists material flow of outfeeding

- LCD touch panel : Easily operable human-computer interface to access parameter changes and production monitoring

- Socket type IC circuit control : Automated control system can be easily replaced by socket plugin.

- Malfunction alarm / stop : Alarm & auto-stops for abnormal temperature / No material feed / Photocell tracking miss (3 times)

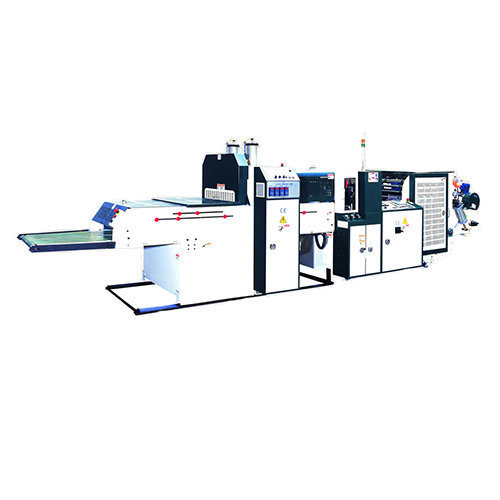

32TPFA-V+SLG2+AP

Bag Width:3"-14"x2

Bag Length:10"-26"

Film Thickness:0.012mm-0.025mm

Film Thickness:0.012mm-0.025mm

Capacity (strokes/min):200/250/300