Main Machine

Servo Driven System / Twin Servo System

High accuracy with photocell positioning and high response speed for printed bags

Available in 200cpm / 250cpm / 300cpm models

Hot-cut System

Top and bottom heat-sealing system for strong sealing with high sealing speed

Tensionless sealing avoids sealing line elongation

Individual temperature control can be easily adjusted for sealing performance.

Sealing Displace

Rocking sealing unit displaces sealing lines to avoid heated seams re-bonding to previous one

"SICK" Photocell

Reliable and accurate photocell registration with long service life

LCD Control Interface

Touch screen interface for easy parameter and production monitoring

Minimum Blank Cut

No blank cut between gripping time to maximize production output

Malfunction Alarm / Stop

Abnormal temperature / No material feed / Photo-cell track miss

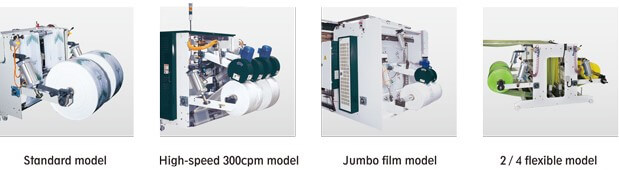

Unwinder System

Pneumatic Liftarm Film Mounting Device + Airshaft

ㆍWeb tension control - AC motor + inverter control maining stable web tension throughout production period

ㆍHigh-speed pressor roller - Assistive motor driven pressor roller helps unwinding for high-speed model and heavy jumbo film rolls

ㆍ 2 / 4 back to back unwinding system -Unwinding 2 Iarge or 4 small films rolls for 2 or 4 lines production

ㆍFor easy operation of heavy film rolls by single operator

ㆍAvoid occupational iniury

ㆍAirshaft helps fast loading and positioning

ㆍ Unwinding up to dia. 1200mm film rolls

Gripper & Punch System

ㆍGripper device & Pneumatic punch - In-line Gripper ㆍWaste removal - Punched out waste are removed and punch collecting when counts reached by gripper and collected by side conveyor, recycle

ㆍOptional inline gripper fold - Programmed gripper inhouse waste for high product quality and less cycle and machine function folds T-shirt bags piles color masterbatch in half to simply labour collection work

ㆍWaste removal - Punched out waste are removed by gripper and collected by side conveyor, recycle inhouse waste for high product quality and less color masterbatch

Optional Device

Hot-cut round punch

Hot-cut round punch device punches and melt layers of T-shirt bag together with the pneumatic punch device. The header part of the piles can be hanged and bags can be tear-off piece by piece by end-user.

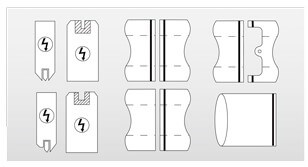

K sealing device for standup T-shirt bag

K-shape sealing device are used as an extra station to seal the deep gussets together. The bag will form a rectangular bottom for items such as cartons, paper boxes with flat and angular base.

Easy open spray device

Easy-open T-shirt bags are loaded on racks for easy packaging. Bags material has static charge & pressing mark and while cashier removing the bag the next one will open up. Optional spray devices to spray the bags piece by piece to achieve same performance.

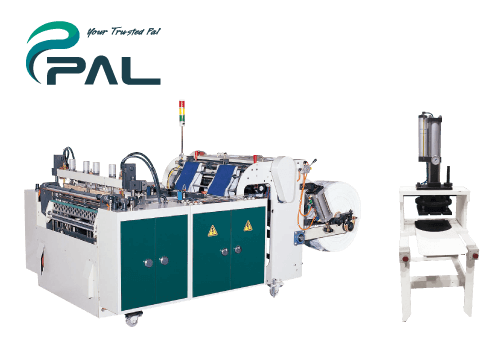

High-speed T-shirt Bag Making Machine Off-line Punch System

Model:P/TP-V

Manual pneumatic punch device (PD70 / 90)

Manual pneumatic punch device (PD70 / 90)

Available System

ㆍAvailable production line: 1 / 2 lines

ㆍHighspeed models:200cpm / 250cpm /300cpm

ㆍAvailable models: 24" / 28" / 32" / 42"

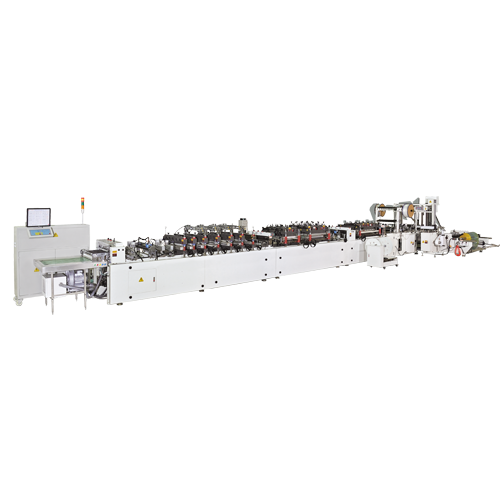

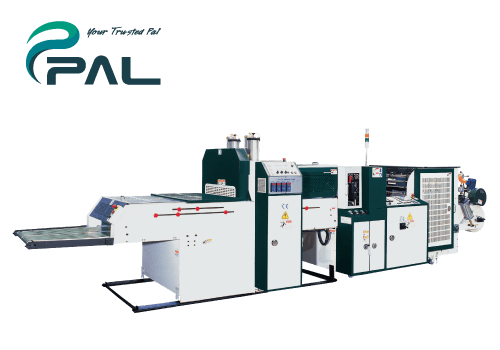

Highspeed T-shirt Bag Making Machine In-line Punch System

Model:PFA /TPFA-V

ㆍStandard highspeed hot-cut T-shirt bag system for printed T-shirt bag

ㆍIn-line gripper & punch

Available System

ㆍAvailable production line: 1 / 2/3 lines

ㆍHighspeed models: 200cpm / 250cpm / 300cpm

ㆍAvailable models: 24" / 28" / 3 32"142"/50"165"

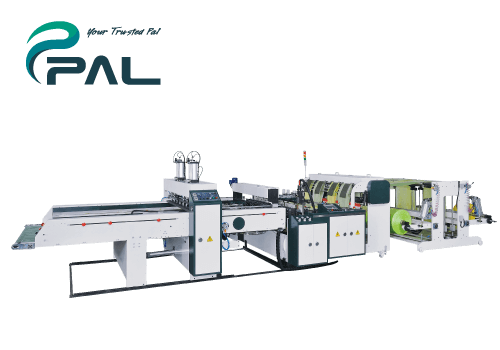

High-speed T-shirt Bag Making Machine Flexible 2 Lines & 4 Lines System

Model:TPFA-V-2/4

ㆍ2 Servo feeding / 4 unwinders

ㆍ2 or 4 sealing knives / 2 pneumatic punch

ㆍAdaptive production to market change between large and small bags

Available System

ㆍHighspeed models:200cpm / 250cpm / 300cpm

ㆍAvailable models: 46" / 52" / 56"

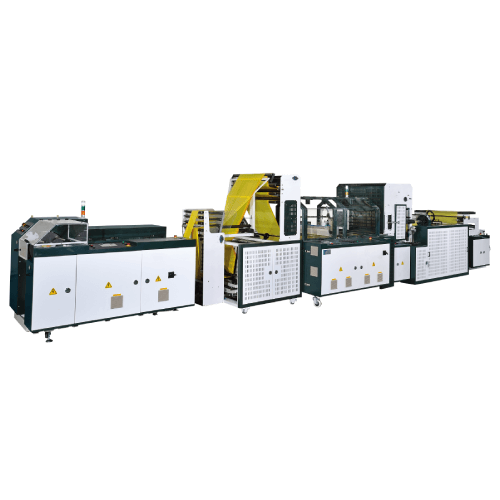

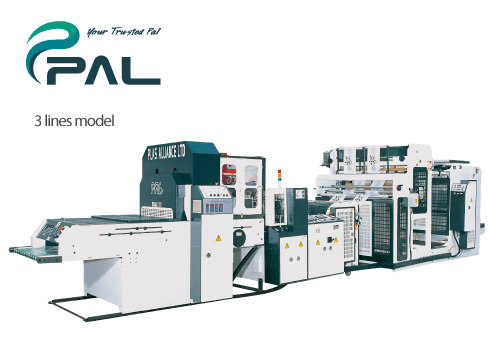

Highspeed T-shirt Bag Making Machine Heat-slitting & Post-gusset System

Model:PFA-V+SLG

Available System

ㆍAvailable production line:2/3/4/5/6 lines

ㆍHighspeed models:200cpm / 250cpm / 300cpm

ㆍAvailable models: 32" / 42" / 50" / 65"

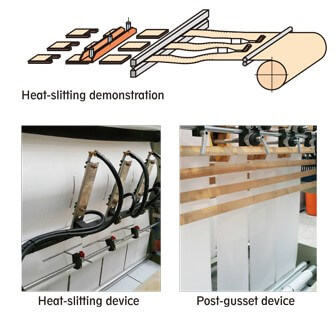

One Time Film Blown & One Time Printing

High production efficiency by blowing up one jumbo film roll instead of several small rolls.

Large film roll, after printed, could supply for multiple lines production

Benefit: Greatly reduce labor cost, production time and energy consumption.

Heat-slitting & Post-gusset System

ㆍHeat-slitting - Heated semi-circular knife slit and seal the edge of passing film

ㆍPost-gusset - Blow up tubic film again and form gusset as film blown machines

PAL offers different types of production system for T-shirt bag, each suitable for different production lines and setup based upon the investment and other existing extruders & printing machines.

Selection for systems listed below based upon the properties:

Economy Off-line Punch System

ㆍ Economy for machine investment ㆍFully automatic inline punch and stack

ㆍSuitable for low labor costs *Suitable with standard 45 & 55 film blown machine

ㆍ Requires labor for punch out off-line ㆍDifferent speed options available

Flexible 2/4 Line System

ㆍFully automatic inline punch and stack ㆍLarge output volume.

ㆍSuitable for large printed bags and small non- printed bags

ㆍMaximize output for small bags

ㆍCompatible with standard 45 & 55 flm blown machine

Standard In-line Punch System

ㆍFully automatic inline punch and stack

ㆍSuitable with standard 45 & 55 film blown machine

ㆍDifferent speed options available

Heat-slitting & Post-gusset System

ㆍ Large output volume.

ㆍLower costs by 1 time film blown & 1 time printing

ㆍCompatible with large film blown & printing machine

ㆍHigher initial machine investment

ㆍMarket must accept heat-slit bag

Auto-packaging Solution

As labour cost becomes increasingly expensive, manufacturers demand better technology which

automate the packaging process and further reduce the labour costs.

Outer Packaging For Individual Packs

Each individual piles packaged with a printed /non-printed film for retail market distribution.

PAL offers customized auto-packaging solutions based on the finished goods packaging styles and transportation packaging.

Carton Loading For Transportation

For delivery to retail store, finished pile are conveyed and loaded in to cartons and later sealed for loading on pallet and delivery.

We are your trusted PAL for auto-packaging solutions.

Innovative Design

Based on customer needs for special packaging type and ideas for higher output setup. PAL is

able to develop upon our existing systems & knowhow to innovate new machines. By discussion and understanding, we could construct an idea and actuate the systems for production of new packaging ideas.

| Model | Bag length (inch) | Bag width (inch) | Cutting speed (strokes/min) | Film thickness (mm) | Tolerance | Power | Machine dimension L x W x H (cm) |

| High Speed T-shirt Bag Making Machine, Off-line Punch System | |||||||

| 24P-V | 10-30 | 6-22 x 1 | 200 / 250 / 300 | 0.01-0.25 | ±1 | 3.8 | 300 x 140 x 130 |

| 32P-V | 10-30 | 6-14 x 2 | 200 / 250 / 300 | 0.01-0.25 | ±1 | 4.0 | 300 x 160 x 130 |

| 42P-V | 10-30 | 6-19 x 2 | 200 / 250 / 300 | 0.01-0.25 | ±1 | 5.0 | 300 x 160 x 130 |

| Twin Servo High Speed T-shirt Bag Making Machine, Off-line Punch System | |||||||

| 32TP-V | 10-30 | 6-14 x 2 | 200 / 250 / 300 | 0.01-0.25 | ±1 | 5.0 | 300 x 160 x 130 |

| 42TP-V | 10-30 | 6-19 x 2 | 200 / 250 / 300 | 0.01-0.25 | ±1 | 6.0 | 300 x 160 x 130 |

| High Speed T-shirt Bag Making Machine, In-line Punch System | |||||||

| 24PFA-V | 10-26 | 6-22 x 1 | 200 / 250 / 300 | 0.01-0.25 | ±1 | 5.6 | 700 x 150 x 200 |

| 32PFA-V | 10-26 | 6-14 x 2 | 200 / 250 / 300 | 0.01-0.25 | ±1 | 6.0 | 700 x 170 x 200 |

| 42PFA-V | 10-26 | 6-19 x 2 | 200/250/300 | 0.01-0.25 | ±1 | 6.7 | 700 x 190 x 200 |

| Twin Servo High Speed T-shirt Bag Making Machine, In-line Punch System | |||||||

| 32TPFA-V | 10-26 | 6-14 x 2 | 200 / 250 / 300 | 0.01-0.25 | ±1 | 7 | 700 x 170 x 200 |

| 42TPFA-V | 10-26 | 6-19 x 2 | 200 / 250 / 300 | 0.01-0.25 | ±1 | 7.7 | 700 x 190 x 200 |

| Fully Automatic High Speed T-shirt Bag Making Machine + Heat-slitting & post-gusseting System | |||||||

| 32PFA-V+SLG2 (2 lines) | 10-26 | 6-14 x 2 | 200 / 250 / 300 | 0.01-0.25 | ±1 | 5.8 | 700 x 190 x 200 |

| 42PFA-V+SLG2 (2 lines) | 10-26 | 6-19 x 2 | 200 / 250 / 300 | 0.01-0.25 | ±1 | 6.5 | 700 x 190 x 200 |

| Fully Automatic High Speed T-shirt Bag Making Machine + Heat-slitting & post-gusseting System | |||||||

| 44PFA-V+SLG3 (3 lines) | 10-26 | 6-13 x 3 | 200 / 250 / 300 | 0.01-0.25 | ±1 | 8 | 700 x 200 x 180 |

| Flexible Twin Servo High Speed T-shirt Bag Making Machine, In-line Punch System (2 & 4 lines) | |||||||

| 46TPFA-V-2/4 | 10-26 | 20 x 2 10 x 4 | 200 / 250 / 300 | 0.01-0.25 | ±1 | 7 | 760 x 210 x 175 |

| 56TPFA-V-2/4 | 10-26 | 24 x 2 12 x 4 | 200 / 250 / 300 | 0.01-0.25 | ±1 | 10.5 | 830 x 235 x 175 |