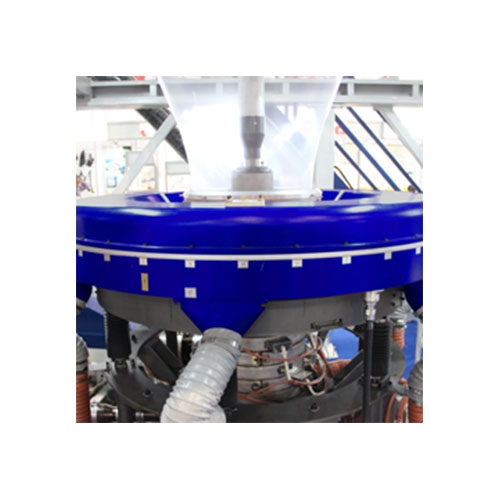

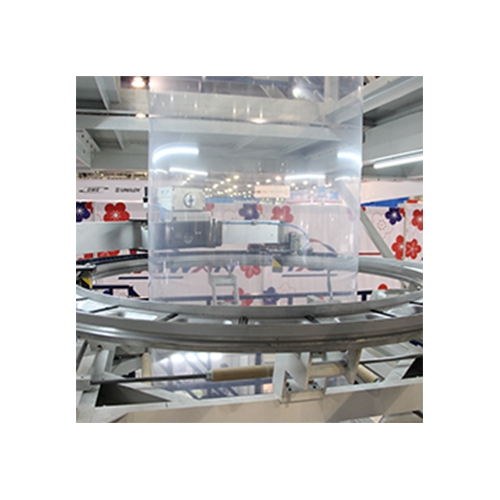

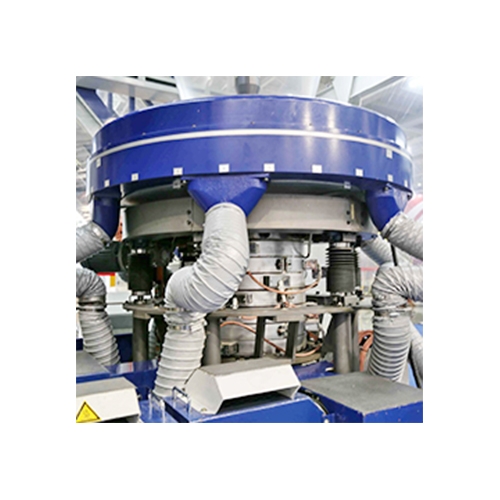

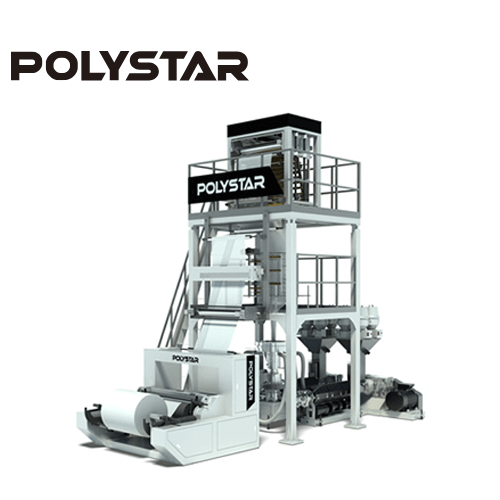

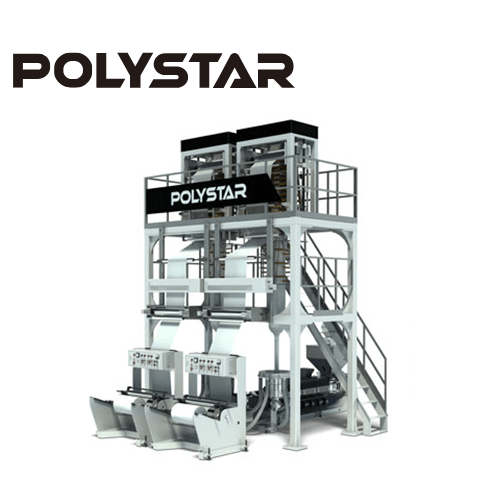

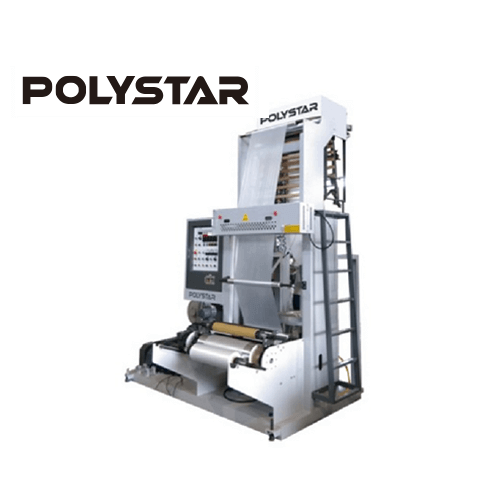

Classification : Multi Layer Film Blowing Line

Country: Taiwan

Phone: 886-2-28011185

Fax: 886-2-28015377

Contact Person: James Chen

Multi layer blown film making line

- Lower production cost/ higher profit margin into the film middle layer UP TO 100% of recycled material or up to 70% of filler CACO3

- Layers Max. idstribution up to 1:3:1

- Excellent quality of outer layer from virgin raw

- Excellent sealing

| Model | META 50-55-50-1300 | META 65-80-65-2100 | META 653-502-1800 |

| EXTRUDER | (B) | (B) | (B+D) |

| Screw Dia. | Ø55 mm | Ø80 mm | Ø50 mm *2 |

| Screw Length L/D | 28/1 (Barrier Screw) | 28/1 (Barrier Screw) | 28/1 (Barrier Screw) |

| Barrel Material | ACM2 | ACM2 | ACM2 |

| Screw Material | ACM2 | ACM2 | ACM2 |

| Gear Material | SNCM 21 | SNCM 21 | SNCM 21 |

| Temperature Control Zones | 3+1 | 4+2 | (3+3) * 2 |

| Barrel Colling System | Air Cooling | Air Cooling | Air Cooling |

| Screen Filter | Standard * 1 | Manual Screen Changer * 1 | Manual Screen Changer * 2 |

| Max. Extrusion | 80 Kgs | 180 Kgs | 55 Kgs * 2 |

| Main Motor | 40 HP A.C Motor with Inverter | 100 HP A.C Motor with Inverter | 30 HP A.C Motor with Inverter * 2 |

| EXTRUDER | (A+C) | (A+C) | (A+C+E) |

| Screw Dia. | Ø50 mm * 2 | Ø65 mm * 2 | Ø65 mm * 3 |

| Screw Length L/D | 28/1 (Barrier Screw) | 28/1 (Barrier Screw) | 28/1 (Barrier Screw) |

| Barrel Material | ACM2 | ACM2 | ACM2 |

| Screw Material | ACM2 | ACM2 | ACM2 |

| Gear Material | SNCM 21 | SNCM 21 | SNCM 21 |

| Temperature Control Zones | (3+1) * 2 | (4+3) * 2 |

(4+3) * 2...A+E (4+2) * 1.....C |

| Barrel Colling System | Air Cooling | Air Cooling | Air Cooling |

| Screen Filter | Standard * 2 | Manual Screen Changer * 2 | Manual Screen Changer * 3 |

| Max. Extrusion | 60 Kgs *2 | 120 Kgs *2 |

110 Kgs * 3...A+C+E 100 Kgs * 2 ...A+E, 50kgs *1...C |

| Main Motor | 20 HP A.C Motor with Inverter * 2 | 60 HP A.C Motor with Inverter * 2 | 60 HP A.C Motor with Inverter * 3 |

| Inflation Spiral Dies | 300 OR 400 Ø MM (A+B+C+D+E) | ||

| Control Zone | 5 | 8 | 6 |

| Thickness of Tube | 0.02-0.15 mm | 0.02-0.15 mm | 0.02-0.15 mm |

| Width of Tube | 1200mm/Max | 2000mm/Max |

1700mm/Max...PE 1300~1600mm/Max...PA |

| COOLING EQUIPMENT | |||

| Aluminum Alloy Air Ring |

Low Pressure High Air Velocity Design Air Ring |

Low Pressure High Air Velocity | Design Air Ring |

| Air Blower | 10 HP A.C with Inverter | 20 HP A.C with Inverter | 20 HP A.C with Inverter |

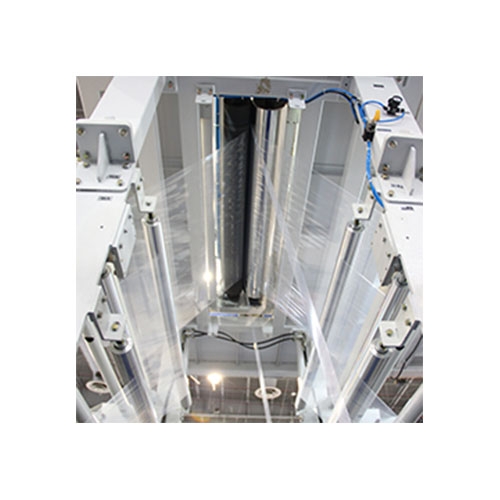

| TAKE-UP MACHINE | |||

| Rubber Roller | Ø160 * 1300 L/mm * 1 | Ø210 * 2100 L/mm * 1 | Ø210 * 1800 L/mm * 1 |

| Hard Chromium Steel Roller | Ø160 * 1300 L/mm * 1 | Ø210 * 1800 L/mm * 1 | Ø210 * 1800 L/mm * 1 |

| Aluminum Guide Roller | Ø75 * 1300 L/mm * 4 | Ø100 * 2100 L/mm * 4 | Ø100 * 1800 L/mm * 4 |

| Take-up Motor | 1 HP A.C with Inverter | 2 HP A.C with Inverter | 2 HP A.C with Inverter |

| Take-up Speed | 8~60 M/Min/Max | 6~40 M/Min/Max | 6~40 M/Min/Max |

| Bubble Stabilizer | 1 Set | 1 Set | 1 Set |

| Expand Roller | 1 pc | 1 pc | 1 pc |

| WINDER | FBW TYPE DOUBLE WINDER | FAW TYPE DOUBLE WINDER | FDW TYPE FULLY AUOT. DOUBLE WINDER (SURFACE JUMBO TYPE) |

| Winder Motor | 1HP DC TORQUE | 2HP DC TORQUE | 2HP AC+INVERTER |

| Winding Rubber Roller Dimensions |

Ø260 * 1300 L/mm Ø110 * 1300 L/mm |

Ø260 * 2100 L/mm Ø110 * 2100 L/mm |

Ø180 * 1800 L/mm |

| Aluminum Roller Dimensions | Ø75 * 1300 L/mm * 1 | Ø100 * 2100 L/mm * 1 | Ø100 * 1800 L/mm * 1 |

| Second Pinch Roller Motor | 1HP DC TORQUE | 2HP DC TORQUE | 2HP DC TORQUE |

| Second Rubber Roller | Ø110 * 1300 L/mm | Ø160 * 2100 L/mm | Ø160 * 1800 L/mm |

| Second Hard Chromium Steel Roller | Ø160 * 1300 L/mm | Ø210 * 2100 L/mm | Ø210 * 1800 L/mm |

| Expand Roller | 1 pc | 1 pc | 1 pc |

| Pneumatic Valves | 1 Package | 1 Package | 1 Package |

| Max. Winding Dia | Ø1000mm | Ø600mm | Ø1000mm |

| Max. Winding Width | 1199mm | 2000mm | 1700mm |

| Machine Height | 7.6~8.6 M/H | 11.6 M/H | 11.6 M/H |