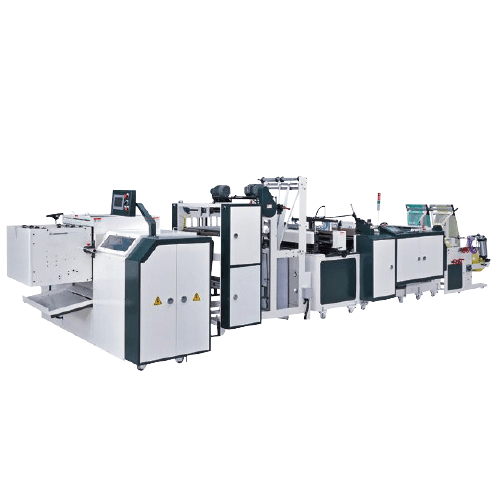

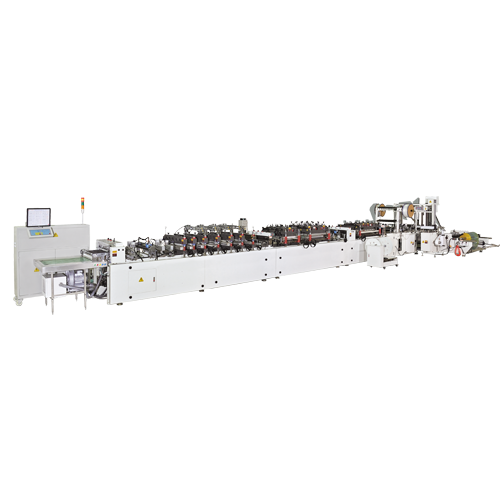

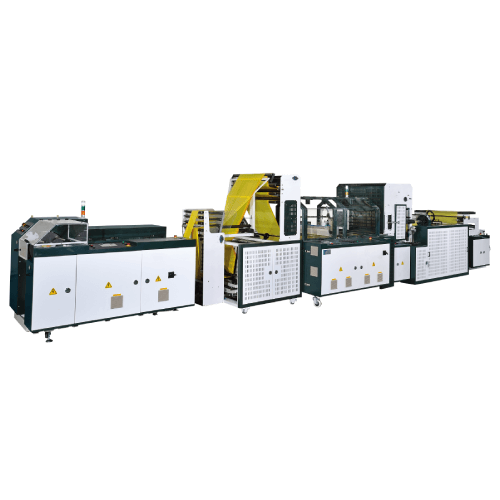

Classification : Bag on roll series

Country: Taiwan

Phone: 886-5-2217005

Fax: 886-5-2211929

Contact Person: Sammuel Chiu

- Up-down die cut - Synchornized up-down die cut & feeding ensures stable & high speed performance. Vacuum waste film removal system for T-shirt bag on rolls.

- Fully automatic rewinder - Fully automatic non-stop system inserts paper core & change finished roll. Coreless rewinder uses 2 sets of forks for automatic non-stop finished roll change.

- High-speed hot-cut system:Upper sealing blade & bottom heating wire makes strong and high-speed sealing. Separate upper and bottom temperature control for easy micro-adjustment.

- Synchronized Feeding and cutting speed:Inverter controlled feeding matching main machine speed for easy operation without manual adjustment.

- German "Sick" photocell registration:Reliable and accurate print registration and positioning

- LCD touch panel:Easily operable human-computer interface to access parameter changes and production monitoring

- Socket type IC circuit control:Automated control system can be easily replaced by socket plugin.

- Malfunction alarm / stop:Alarm & auto-stops for abnormal temperature / No material feed / Photocell tracking miss (3 times)

| 32BFWDFA-V | 42BFWDFA-V |

| Bag Width:3"-30"x1 or 3"-11"x2 Bag Length:10"-30" Film Thickness:0.012mm-0.15mm Capacity (strokes/min):30-70 |

Bag Width:3"-40"x1 or 3"-17"x2 Bag Length:10"-30" Film Thickness:0.012mm-0.15mm Capacity (strokes/min):30-70 |