Screws / Barrels for Extrusion and Injection Molding | NAN YUN

As leading company of Screws and barrels in Taiwan, Nan Yun is able to provide the highest quality screw and barrel for Extruder Machine. We are continually researching new screw and barrel materials that would best fit the needs for pellet extruder or plastic pelletizing machine, which results in better mixing, and critical melt quality. Nan Yun's engineers work with our customers to provide the best possible extruder screw design for extruder machine such as PVC pelletizing machine, PE pelletizing equipment, Plastic pellet extruder.

Exclusive Interview: Jawhari Kamil on the 20th Saudi PPPP and Vision 2030

Join host Jason as he sits down with Jawhari Kamil, chief organizer of the 20th Riyadh Expo, for an insider’s look at this landmark event. In just a few minutes you’ll learn: What makes the 20th Saudi PPPP and how it reflects Saudi Arabia’s rapid industrial momentum Kingdom Vision 2030 in action—why national transformation goals are shaping every corner of the show Sustainability in focus: from low-carbon solutions to green partnerships that matter A surprise reveal: Jawhari hints at a major collaboration with a world-famous exhibition coming in 2026—watch to the end to find out which one! Whether you work in plastics, packaging, or any sector eyeing the Middle East, this interview delivers fresh insights you won’t want to miss.

Assembling Video of Two Platen Injection Molding Machine - 3000TP | CLF

【ASSEMBLING VIDEO】 Two Platen Injection Molding Machine 3000TP from CLF. CLF is specializing in manufacturing plastic injection molding machines with super-large, high precision, and high performance.

International Market Outlook | PRM What to Say EP3

International Market Outlook | PRM What to Say EP3 In this episode, we are talking about Taiwanese stock prices and machinery export. Moreover, the price of raw materials has been rising for many months in accordance with many factors, which will be mentioned as well, such as marine logistics, Texas blackout, and so on. During the tough period of the pandemic, we will go through how Taiwanese manufacturers cope with problems to serve their customers and what they are planning to do. Wish everyone to stay safe and healthy to fight and overcome this circumstance. Know us more on: PRM YouTube: https://www.youtube.com/c/PRMTaiwan PRM Facebook: https://www.facebook.com/PRMMediaChannel PRM LinkedIn: https://www.linkedin.com/company/prm-taiwan/ VIDEO OUTLINE 0:00 Highlights in Episode 3 & Video Intro 0:45 Stock Prices & Machinery Export in Taiwan 2:28 Reasons for Price Change of Raw Materials 5:09 When Raw Materials Prices Come Back to Normal? 7:37 Vaccine & Current Situation in Taiwan

2023 IPF Taiwan Manufacturer Interview | POLYSTAR

It is a great honor to invite Sumit from POLYSTAR to share the changes in Bangladesh's industry after the pandemic and the differences between the Bangladesh market and the India market.

Online and Offline Machinery Information for you! | PRM What To Say EP15

In this episode, we will uncover a series of online and offline information about machines and manufacturers related to the Plastics and Rubber Industry. Due to the pandemic many international exhibitions have been cancelled, postponed or even transformed into a digital exhibition. This has led us to become victims of the ones who attend international exhibitions. Nevertheless, for every challenging time there's always an opportunity to develop and become better. Following this philosophy we have brought a solution for the international companies in the related field who have been affected by the current situation. Check the video above to know more about the solutions we bring to the ones who are passionate about attending international exhibitions!

SIAF 2021 Guangzhou Exhibition Opens Door | PRM-TAIWAN

【 PRM-TAIWAN on SIAF Guangzhou 2021 Exhibition 】 Info: Great news for PRM-TAIWAN, Taiwanese Suppliers, and all the buyers who have put their trust in us! Despite COVID-19, we are glad to announce that thanks to our branch office in China, PRM has come back to the international exhibition ground to do what we do best - Provide professional services to international buyers! PRM-TAIWAN Plastics and Rubber B2B Platform: https://bit.ly/377P7Vv To keep updated about the latest news of the Plastics and Rubber Industry, please follow us on our Social Media Channels: PRM-TAIWAN Facebook: https://www.facebook.com/PRMTAIWAN PRM-TAIWAN LinkedIn page: https://www.linkedin.com/company/prm-taiwan/

Solventless Laminating Machine (LM SF1300T) | WEBCONTROL

Webcontrol develops innovative solventless laminators with driven coating system and automatic turret unwind & rewind for high efficiency, consistent tension & minimum waste during roll changes.

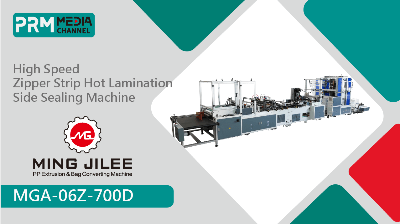

High Speed Zipper Strip Hot Lamination Side Sealing Machine | MING JILEE

【Machine Features】 Taiwan-made and stable PLC controller The size control of Zipper Bag Side Sealing Machine is by servo motor. Made in Japan. Zipper Bag Side Sealing Machine is equipped mark sensor for printed material. For getting the best quality of zipper bag product, unwinding station is mount the auto tension control. The individual zipper strip unwinder with motor control to get the high quality of zipper sealing quality. Ultrasonic welding is design by motor driven for highest speed production. The ultrasonic welding station to crack the zipper on the edge of the bag for easy side sealing cutting. 【Company Intro】 Ming Jilee Enterprise Co., Ltd. is manufacturing film blowing machinery with materials of PP and LD/HDPE; PP thin and thick sheet making machine; waste recycling and pelletizing machine, stationery making machinery- can produce business file/data bag/file clip/photo pocket/name card pocket/index/bubble paper envelope; sealing & cutting machinery-side sealing bag/t-shirt bag.

Triangle Folding Machine, 1 Color Rotogravure Printing | MING JILEE

Triangle Folding Machine, 1 Color Rotogravure Printing, MGA-27B-1000 from MING JILEE Specializes in Triangle folding machine , Ming Jilee Enterprise Co., Ltd. established in 1987 and received ISO-9002 approval for Triangle folding machine and exporter. Our Triangle folding machine products are all as our business policy: high-tech quality, competitive price, best service, on time delivery, and more for sealing and cutting machine services.

MOLD TEMPERATURE CONTROLLER, YANN BANG

YANN BANG, Patented Mold Temperature Controller, Temperature Controlled Unit Our temperature control unit can use water/oil heating system to secure the high quality of plastic production made by injection, extrusion and blow molding machines. Learn more: https://www.yannbang.com/mold-tempera...

2023 IPF On-site Tour | PRM

IPF Bangladesh 2023 Bangladesh Exhibition covers "three main industries", including plastics, packaging and printing industries, creating opportunities for buyers and manufacturers to communicate with each other! Let PRM Alice show you the IPF Bangladesh 2023 exhibition!

2023 IPF Taiwan Manufacturer Interview | HCI

While at the IPF Bangladesh industry fair, we certainly couldn't miss HCI Industry, which has been operating in the Bangladesh market for many years. This time, Jacky from HCI has shared his point of view on Bangladesh's industry and how Taiwan does business in Bangladesh. We have talked about the differences between the markets in other Asian regions. Let's take a look at HCI Jacky's interview.

Best Choice Of PET Extrusion Pelletizing Machine Line From Partico Machinery, Inc | PARTICO

Model no:HF-FTO-135 3 in 1- Flow Channel Pelletizing System Double Filters system: no.1 Double pistons(Back flush) no.2 CPF Spec:The dia of screw 135mm Output:500-600kg/hr Application:PET yarn, flakes, fiber, filament

CHINAPLAS 2021 PRM Trade Show Activities | PRM Media Channel

Throwback to CHINAPLAS 2021 to share the online and offline events of PRM. More Info About PRM Online Exhibition: https://bit.ly/3f1UN8t Let's take a look at PRM Trade Show Activities related to this biggest plastics and rubber industry exhibition in Asia. It was our pleasure to attend CHINAPLAS 2021 this year. Since the pandemic, the foreign visitors and exhibitors have been fewer than in previous years; however, PRM understands our customers' and international buyers' circumstances. In this video, you will find our exhibition activities, including matchmaking buyers and manufacturers of the plastics and rubber industry through our in-time inquiry system. During the exhibition, PRM observed the Chinese market and CHINAPLAS, also we have interviewed exhibitors to gather more profound insight into the market. You can find detailed information on our Youtube Channel, E-newsletter, and social media platforms that are provided below. We also cooperated with Adsale, the organizer of CHINAPLAS, to bring out interview videos and the Livestreams about the current situation of the plastics and rubber industry and their solutions. For more information and videos, please visit our PRM-TAIWAN TechHub@CPRJ at https://bit.ly/3f1UN8t Follow PRM Media Channel on: YouTube: https://www.youtube.com/c/PRMTaiwan Facebook: https://www.facebook.com/PRMTAIWAN Linkedin: https://www.linkedin.com/company/prm-taiwan/

Packaging Industry Trends and Obstacles | PRM What to Say EP5

In the fifth episode of the PRM What to Say program we interview Ms. Wang, the Chairperson of Taiwan Packaging Association. Through the interview that our team member Sunny held, we touched several current topics related to the packaging industry, online and physical trade shows, food food safety, shelf life and modern packaging designs, the association’s support for the members and so on. Since the beginning of the outbreak many machinery industries are facing several common obstacles such as logistics, machinery installation and maintenance. For the many machinery categories, the demands are suspended. However, for the packaging industry, the situation is more specific. Due to the global lock downs, the housing economy has been revived and the needs for food packaging and cargo packaging boomed. On the other hand, the machine manufacturers are still facing the common obstacles of the pandemic to reach out to their customers.

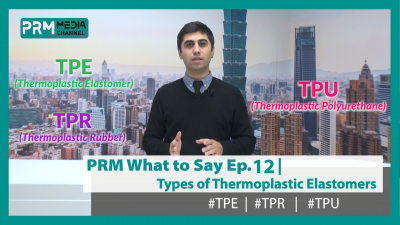

TPE, TPR, TPU Materials Explained | PRM What to Say EP12

In this episode, we will open a special page for TPU and TPE, TPR materials. Because there are several common confusions about them. Then, let’s understand the differences and fields of application of those innovative materials together. 【TPE/TPR】 Both TPE(Thermoplastic Elastomer) and TPR(Thermoplastic Rubber) belong to the family of Thermoplastic Elastomers, and there isn’t a defined industry standard to distinguish them. But, it is certain that TPE is made from SEBS, while TPR is made from SBS block copolymers. [TPE/TPR Applications] TPE/TPRs are great for anywhere that flexibility, comfort, or cost savings are needed. They are a top choice for medical applications like surgical and dental tubing and also tubing used in the food/beverage industry. 【TPU】 TPU(Thermoplastic polyurethane ) is a soft polyether type polyurethane that is available in a range of hardness grades, which gives a diverse application range to TPU. There are two main types based on soft segment chemistry: Polyester-based TPUs, and Polyether-based TPUs. [TPU Applications] With their resistance properties, TPU is superior for use anywhere that ozone, extreme temperatures, and high levels of abrasion are a concern. In addition to medical uses, TPU is also a popular material for sporting goods, tubing, wire, protective coatings, and more. All those materials above are alternatives for natural rubber and are easy to manufacture. Moreover, those materials can be 100% recycled.

Recycling Solutions for Packaging Industry | POLYSTAR Interview

At the recent TAIPEI PACK 2020, the famous packaging machinery exhibition of Taiwan, we have interviewed Ms. June Pei, from POLYSTAR. POLYSTAR is one of the most famous and leading recycling and blown film machines manufacturer from Taiwan, and has sold machinery in many countries around the globe. Ms. Pei shared her opinions and observations about the packaging industry, their recycling solutions related to the packaging industry, and also introduced the machinery they are showcasing at the exhibition. Moreover, she also mentioned the implementations to ease the effects of the pandemic on the business and the solutions they provide to their current and potential customers. Let's watch the interview video together and learn more. Thank you for your opinions and questions that you can leave as a comment. Remember to subscribe to our social media channels for the forthcoming interview videos and similar videos!~

Customization & After-sale Service | GENIUS

More and more countries request all plastic-made products to be fully recycled; therefore, plastic recycling machines have been important. Mr. Peter Tsai, the general manager of Genius, explained the best seller “Single Stage Cutter Compactor Plastic Recycling Machine” as known as KRIEGER series in their product lines. This machine is capable of recycling HDPE drums and films with superior features, such as Italian-made heater, extruder-degassing vents, dual piston filters. With excellent customer satisfaction and customization service, Genius awarded an order from a returning Japanese client again. According to the language and the use habits, the parts of the machine have been installed with many Japanese brands in order to lessen obstacles while Japanese employees operate the machine. Moreover, Peter has expressed how Genius values customer satisfaction, customization service and after-sales service in the interview. Through this video, you will be showcased how Genius is running the testing of Single Cutter Compactor Machine before shipment. 【Brief Intro】 Genius Machinery specializes in the comprehensive plant planning of plastic recycling equipment. With over 40 years of experience in designing and manufacturing plastic recycling equipment. 【Video Outline】 00:00 - Introduction 00:31 - Machine Testing & Superior Features 02:10 - Conveyor Belt 02:19 - Compactor 02:50 - Extruder-degassing 03:19 - Dual Piston Filter 03:40 - Pelletizer 04:18 - Details of customized control panel 05:21 - Materials Process & Applications of Machine 06:27 - After-sale service for installation & maintenance 08:05 - Messages to customers

Twin Head Blown Film Machine for Plastic Bag Manufacturers | POLYSTAR

Introducing POLYSTAR Twin Head Blown Film Machine with the motto of the company: "Extrusion Made Simple". The blown film extruder is specially designed for HDPE and LDPE bag producers. 【HIGHLIGTS OF Twin Head Blown Film Machine】 - Monolayer (1 Layer) - Two Die Heads, Single Screw - Film Width from 150~650mm - Extruder Dia: 45mm, 55mm, 75mm - Material: HDPE, LDPE - Output: 30~140 kg/hr - Works with virgin, recycled materials, Biomaterials, and CaCO3 - Possible end products: T-shirt bags, Bottom sealed flat bags, Shopping bags, Supermarket bags, Garbage bags 【MACHINE PORTFOLIO OF POLYSTAR】 1. BLOWN FILM MACHINES - One Layer Twin Head HDPE LDPE 650mm Machine - Multilayer Blown Film Machines - One Layer HDPE / LDPE 800mm (Mini type) Machine - AB - 2 Layer Co-Extrusion LDPE/LLDPE Machine - One Layer HDPE LDPE LLDPE 1500mm Machine 2. BAG MAKING MACHINES - Bottom Sealing Bag Making Machines - Folded Garbage Bags Machines - Perforated Bag on Roll Machines - Thick Bag Making Machines - Laundry Bags Machines 3. RECYCLING MACHINES - Plastic Recycling Machines - Plastic film recycling Machines - Two stage recycling Machines - Air cooled recycling Machines - Hopper feeding recycling Machines - Shredder integrated recycling Machines 【ABOUT POLYSTAR】 POLYSTAR is a pioneer manufacturer of Plastic Recycling Machines, Blown Film Extruders, and Plastic Bag Making Machines. The company has gained the trust of its customers with 32 years of experience in the industry, today POLYSTAR has been sold over 4,000 machines in 105 countries worldwide.

5 Benefits of Flexo Printing Machines | PRM What to Say EP11

There are several types of printing techniques available for the plastic packaging industry. Such as flexo printing, offset printing, and screen printing. Although flexo printing is not a new technology, it is the most common method for packaging printing. Then let’s take a glimpse of the video to understand what flexo printing is and what makes it most preferable. Flexographic printing is a technique that uses a flexible printing plate. The plates are wrapped around cylinders on a web press. The inked plates have a raised image and rotate at high speeds to transfer the ink through small holes from the anilox roll to the substrate, which is the printed surface. So, what makes flexo printing the most common method? You will find 5 reasons why in the video.

sleeve seaming machine | WEBCONTROL

sleeve seaming machine -K1-SEAM200-Webcontrol - shrink sleeve seamer Webcontrol Machinery Corp has been specializing in manufacture of Seaming Machine since 1988. Webcontrol ceaselessly develop new machine to extend production line for meeting various needs of customers. In additions, we constantly improve our Seaming Machine with new technology, and innovate to enhances its performance, efficiency and reducing waste on production. Our consistently aim is to build high-performance, sophisticated Converting Machinery with inexpensive price as well as providing fast Seaming Machine service ensure our worldwide customers must be satisfied.

Side Entrance Two Stages System | GEOR DING

Side Entrance Two Stages System - Side Entrance Two Stages Die-Face Cutting Recycling & Pelletizing Machine GEOR-DING MACHINERY CO., LTD.. - Manufacturer of Side Entrance Two Stages System and more. We specialize in manufacturing of Side Entrance Two Stages System. The main businesses include: Side Entrance Two Stages System and the planning of the entire plant’s equipment. While the demand for output and quality in Side Entrance Two Stages System worldwide is increasing day by day, our determination for upholding the motto, “Quality is number one. Output comes second. Customer satisfaction. Perfect service”, will never shift. Under your support and encouragement, we will continue to provide quality Side Entrance Two Stages System products and services to higher standards.

Company Introduction | ALFA

Alfa Industrial soul thought - professional quality, put product quality in the first place. Whether it is the procurement of parts in the early stage or the final machine inspection, Alfa Industrial strictly monitors every link, every process and every detail to ensure the stability and performance of each machine. Email: [email protected]

Thermoforming Systems at K 2022 | ILLIG

It was a great honor for PRM to interview the Sales Director — Adam Liang from ILLIG. ILLIG showcased their newest Thermoforming Machine at K 2022. Integrated Sustainability and Digitalization into product applications, including recyclable and biodegradable PP flakes. Mr. Liang also shared his insights for the future in the Plastic & Rubber industry.

Blown Film and Recycling Machines (Chinese Version)- POLYSTAR | CHINAPLAS 2021

PRM Media Channel once again happy to share the great honor of the cooperation with CPRJ, the official media group of CHINAPLAS. Through this cooperation, we aim to provide insights into the Plastics and Rubber industry by the sharing of experts. In this video, we have invited Mr. David Lo, Chief Marketing Officer, to share his knowledge and the overview of Blown Film Extrusion Machines and Plastics Recycling Machines markets. POLYSTAR Machinery is one of the most famous manufacturers especially in recycling machines in Asia with more than 30 years of experience. Besides recycling machinery, the company also well known around the world with its blown film machine lines. Most of the customers of POLYSTAR buy several sets of blown film machines as well as recycling machines together to set a complete line in their factories and contribute to the circular economy. In this video, our PRM Director Alice will be carrying the interview with the CMO Mr. David Lo. During the interview, Mr. David Lo is explaining the advantages for the customers having both blown film machines and recycling machines from POLYSTAR. The following, interview covers several topics including: 1. Advantages of POLYSTAR recycling and blown film machines 2. POLYSTAR contribution to circular economy and examples 3. Simplifying machine design for ease of use 4. Vision and development in 2021

2024 CHINAPLAS Interview | HCI

We are here with Terence from HCI Converting Equipment at the CHINAPLAS. HCI is a specialist in the Converting Equipment and Slitter Rewinder machinery, able to provide from a single machine to whole plant equipment. We heard very valuable information from Terence, thank you so much!

2024 NPE Orlando Interview | ZERMA

In our first interview with Zerma, we had the pleasure of speaking to CEO, Max Paeslack about the innovative shredder they brought to NPE. Significantly, they also reveal the strategic reasons behind the decision to shift their development focus to Shanghai, China.

UHS Turret Slitter Rewinder - UHS-TR | WEBCONTROL

UHS Turret slitter rewinder The UHS-TR model is a proven fully automatic slitter rewinder, offered with many options to fulfill even the most demanding applications: - Cutting-edge slitting systems - Reliable auto cut and transfer - Advanced tension control - Combined with progressive differential winding technology - Precision and capacity at an affordable cost. - UHS-TR a must addition to any plant requiring quality Automatic knife positioning down to 25 mm slit width, double turret unwind, automated finished roll unloading systems are some of the available options to increase productivity, quality and decreasing operator influenced down time. Materials to be processed: Plastic film, paper and laminates Thickness range: -Rigid films: 10 – 200 micron -Soft films: 12 – 300 micron Machine Specification - SLIT UHS TURRET: -Web width:1300 / 1600 mm max -Unwind roll diameter: 1000 mm -Unwind roll weight: 1500 kg -Unwind roll cores: 3” and 6” I.D. -Finished roll diameter: 610 mm max -Finished roll cores: 3” and 6” I.D. -Slit width: 50 mm and up -Machine speed max: 600 m/min (depending on material type/quality) -Winding tension: 0.5 pli to 2.5 pli (11 - 45 kg) standard

【Turnkey】Biodegradable / Compostable Straw Making & Packing Machine | JUMBO STEEL

Jumbo Steel has more than 30 years of experience in manufacturing straw making machines and straw packing machines. Moreover, Jumbo Steel is providing turnkey solutions for your business according to your needs. 【Product Lines】

Plastic Inflation Machine | KANG CHYAU

Plastic Inflation Machine - Twin Head HDPE Plastic Inflation Machine-Kang Chyau Specializes in Plastic Inflation Machine. Since its founding in 1988 Kang Chyau Industry has worked constantly to bring out new and innovative Plastic Inflation Machine products and offer customers a wide range of choices. After more than a decade of work our products are now sold in 62 countries around the globe, a true measure of our success in the Plastic Inflation Machine market.

High Speed Roll To Roll Printing Machine | FOR DAH

The machine is applied for solvent-based ink and direct printing method for woven bag with/without lamination. Available for CMYK color combination to obtain realistic printing quality to enhance packing value. Newly developed printing machine offers max. line speed 250M/Min and “New Type” Auto. Roller Exchanging System for Un-winder & Re-winder.

Sharing Session of Composite Testing and Regulation | PIIF

引言人:ZwickRoell 台灣分公司 潘東生 總經理 報告人:ZwickRoell 德國總部 全球複材產業經理 Dr. Hannes Körber 《塑膠產業創新論壇》定位為 塑膠產業商務交流的平台 塑膠中心本於推動塑膠產業創新的理念,每年辦理一次《塑膠產業創新論壇》活動,透過推動塑膠產業創新,發揮影響力,滿足社會的需求,實踐造福人群的力量。 《塑膠產業創新論壇》每年挑選產業重要關鍵議題,透過主題論壇、研討會、技術展覽…等形式,引領產業最前瞻的趨勢與做法,期盼耕耘成為塑膠產業的年度盛會。 長期展望為透過本論壇匯聚產業夥伴關係成為塑膠產業創新的生態圈。

Sustainability & Development of TPU in Circular Economy | PIIF

引言人:台灣科思創(股)公司 熱塑性聚氨酯事業處 台灣及東南亞區銷售暨市場發展處 楊政遠 處長 報告人:台灣科思創(股)公司 熱塑型聚氨酯事業處 市場發展經理 林祐涵 博士 《塑膠產業創新論壇》定位為 塑膠產業商務交流的平台 塑膠中心本於推動塑膠產業創新的理念,每年辦理一次《塑膠產業創新論壇》活動,透過推動塑膠產業創新,發揮影響力,滿足社會的需求,實踐造福人群的力量。 《塑膠產業創新論壇》每年挑選產業重要關鍵議題,透過主題論壇、研討會、技術展覽…等形式,引領產業最前瞻的趨勢與做法,期盼耕耘成為塑膠產業的年度盛會。 長期展望為透過本論壇匯聚產業夥伴關係成為塑膠產業創新的生態圈。