LATEST UPDATE Subscribe Now

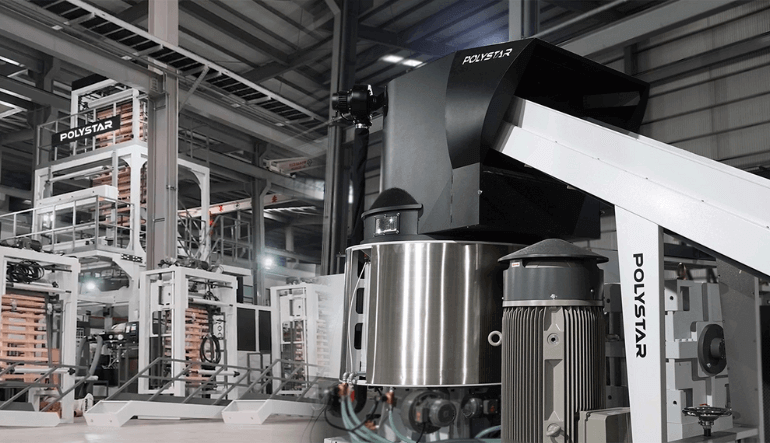

POLYSTAR Co-extrusion & Recycling: Making Plastic Film Sustainable

With the increasing concern over plastic waste and pollution, plastic bag manufacturers are looking for more sustainable production methods to diminish the negative effects of their plastic products. Co-extrusion and recycling are two techniques that are gaining popularity in the plastic film industry. In this blog, we will explore how co-extrusion and recycling can create a circular economy for plastic bag production and minimize waste.

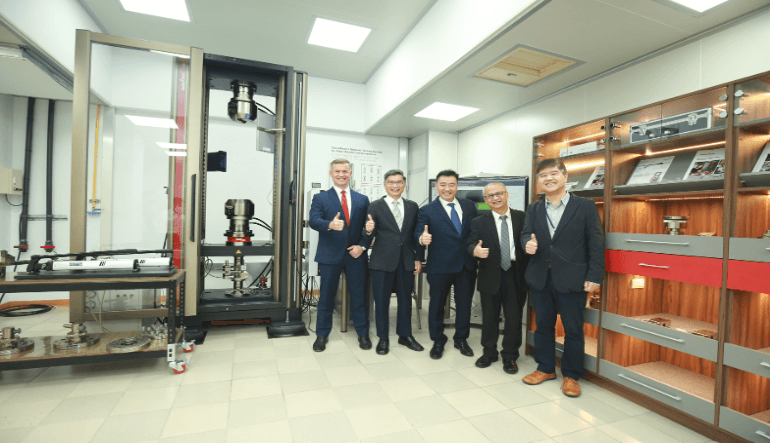

台德合作!塑膠中心促亞太區複材實驗室成立

【新唐人亞太台 2022 年 11 月 24 日訊】 第3屆塑膠產業創新論壇週三(23日)登場,今年以塑膠產業永續發展為題,推出2場論壇及技術研討會系列活動,展出超過100項的焦點技術,吸引塑化業者超過300位出席。 由塑膠中心邱政文副總經理於擔任座談交流會主持人,分享複材產品研發國內已具備技術實力,有賴各界合作,共朝創新高值產品如航太、國防等高階領域開創。天力技術處長王柏棋、塑膠中心博士張修誠,以及虎科大飛機工程系助理教授王正賢,也分享產業技術發展和關鍵人才養成。

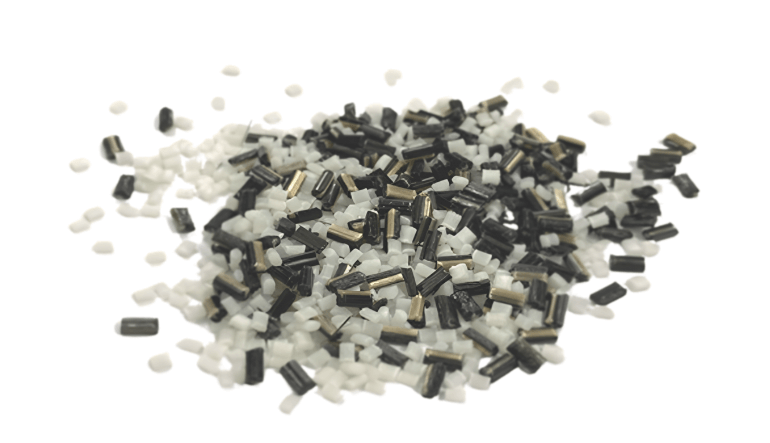

Introduction to ETERPLAST™

ETERNAL ETERPLAST™ thermoplastic composite materials have the characteristics of high strength, high impact resistance, low moisture absorption, high dimensional stability, and repeatable molding. Different temperature-resistant materials can also be provided according to customer needs.

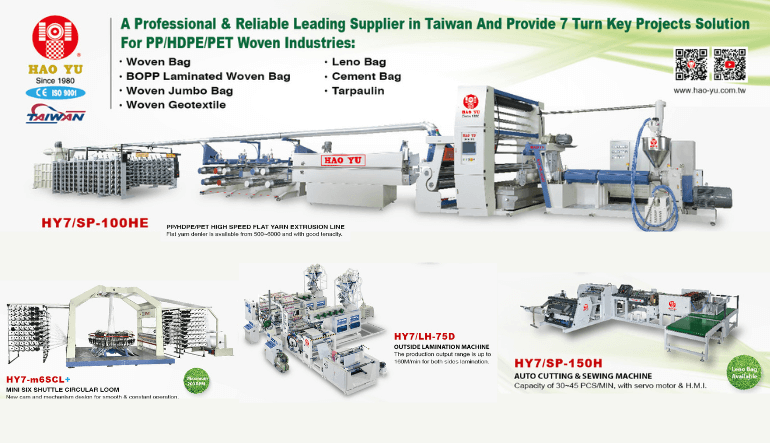

HAO YU: Pioneering Excellence in Woven Bag Machinery Since 1980

HAO YU Precision Machinery Industry Co., Ltd. is a one of the skillful & experienced manufacturers of PP and HDPE woven bag machinery and whole-plant equipment in Taiwan since 1980, HAO YU has been dedicated to the research and development of high performance machinery. Our dedication to continuous research and development is the reason for the excellence.

PRINTPLAS: PRECISION, NO BLUR YOUR BEST PARTNER IN PRINTING BUSINESS!

Printplas Machinery Co., Ltd have been established since 2001 and specialized on the manufacturing of CI & STACK flexographic printing machine in Taiwan. With skilled workers and machine R&D department, we are keeping our efforts to providing precise, stable, high-speed printing machines for our users.

New Productive Forces” to Bring Plastics & Rubber Industries to New Heights CHINAPLAS - Ready to Roll at Shanghai Kick-off Gala

After a 6-year absence, CHINAPLAS, the world‘s leading plastics and rubber trade fair, is ready to make a strong comeback to Shanghai on April 23-26, 2024, at the National Exhibition and Convention Center (NECC), Hongqiao, Shanghai, PR China. To mark this special occasion, CHINAPLAS - Ready to Roll at Shanghai Kick-off Gala was held in Shanghai on March 28. More than 160 industry representatives attended the event in person and over 10,000 industry players participated online to witness the thrilling moment, sailing through high winds toward a brighter future together.

FIMIC at NPE 2024

NPE2024 in Orlando is approaching fast after 6 years of waiting, and preparations are in full swing. FIMIC is returning for the third time to NPE with an array of exciting updates, since 2018 FIMIC has developed technologies offering a wide range of automatic melt filters and has integrated into their product portfolio a screw pump called SPA, available in three different sizes to easily transport the plastic melt without using gears that can be positioned before or after the filter. At NPE2024, FIMIC will display its flagship melt filter, RAS 700 model, showing plastics industry insiders and all other visitors how its technology can be adapted to the application requirements and is designed precisely for filtration processes.

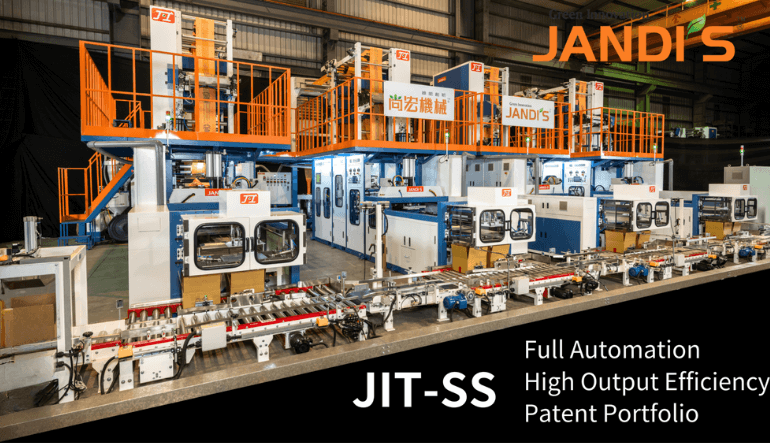

Visit JANDI’S to See the Latest Green Innovation!

Cassava Bag Production : Cassava bag is 100% biodegradable & compostable, also water-dissolved. JANDI’S is working with Avani to offer a Turn-Key Project for production of Cassava bags, including the material supply, marketing strategy, machinery, training and operation skills.

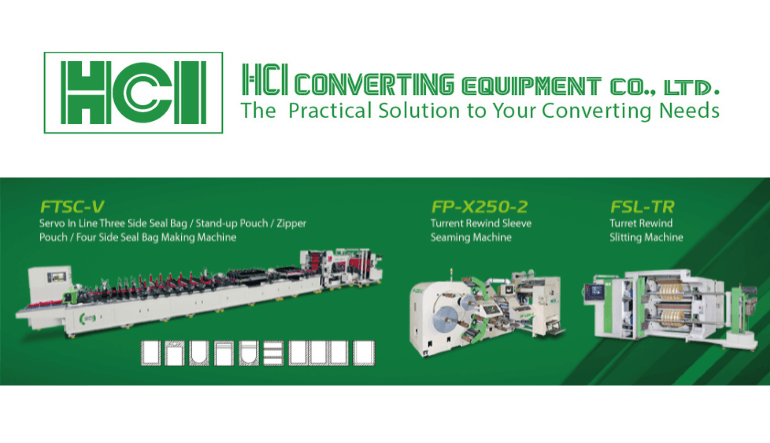

Revolutionizing Flexible Packaging Equipment: HCI's ESG-Focused Innovations

In the dynamic landscape of packaging, HCI is emerging as a transformative force, driving sustainable practices and enhancing user experiences. The integration of HCI into flexible packaging solutions not only adheres to industry standards but also emphasizes a commitment to environmental, social and governance (ESG) principles. HCI principles prioritize user-centric design, enhancing the functionality and accessibility of flexible packaging.

JING DAY: The Strategic Role of Rubber Military Supplies in Modern Warfare

Rubber has long been a crucial material in various industries, and its significance extends to the military domain. From tires to protective gear, rubber plays a pivotal role in enhancing the effectiveness and survivability of armed forces around the world. In this article, we will explore the diverse applications of rubber military supplies and their strategic importance in modern warfare.

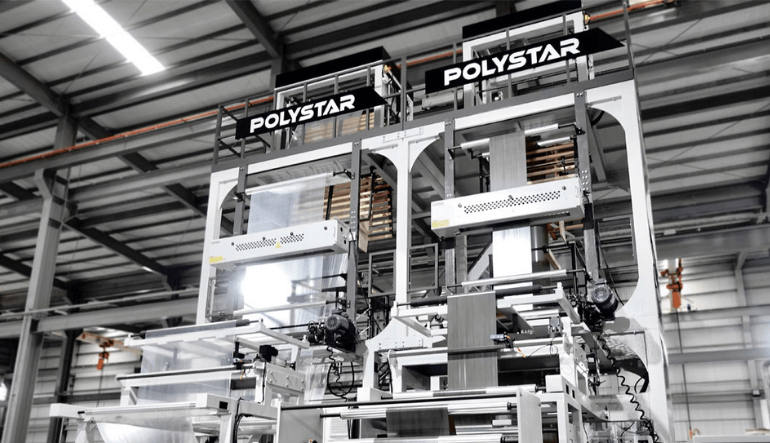

Flexible POLYSTAR Blown Film Extruders for Sustainable Packaging

Eco-friendly packaging is a necessity more than a trend, for both environmental and economic sustainability today. As one of the main carriers of packaging film production, blown film extrusion technology must keep evolving to meet the market requirements. Let's take a closer look into how POLYSTAR develops its blown film extrusion machine technology to better contribute to eco-friendly packaging.

Full Shine Machinery's Expertise in PC Water Bottles Making Machine

Full Shine Machinery has 30 years of experience specializing in Automatic Blow Molding Machines, Multi-layer Co-extrusion Blow Molding Machines (2-6 layers bottle), Accumulator-head Blow Molding Machines, One Stage Injection Blow Molding Machines, and PET Stretch Blow Molding Machines. In addition, we have experience with Molds, Die Heads, and Auxiliary Equipment. Please contact us to learn more about our capabilities.