New Recyclable Hytrel® Foam from DuPont Improves Resilience, Eliminates VOCs

Supercritical fluid (SCF) foaming process applied to Hytrel® creates a new closed-cell foam with lower environmental impact, expanded performance, and greater design freedom.

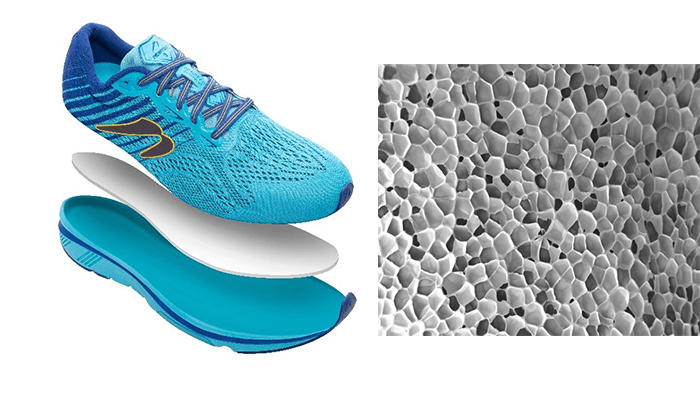

The Newton Gravity 11 running shoe features a full-foot Hytrel® foam insole for cushioning and responsiveness (left). A close-up of Hytrel® foam at 100x magnification (right) shows its closed cell structure.

GENEVA, Switzerland, June 15, 2022 – DuPont Mobility & Materials today announced the commercial availability of new closed-cell Hytrel® foam created via a supercritical fluid (SCF) foaming process. This fully recyclable material is the first foamed product in the Hytrel® product family. It not only reduces environmental impact, but customers already have confirmed that it delivers up to 15% greater resilience and 20% less weight than thermoplastic urethane (TPU, E-TPU), polyurethane (PU), and ethylene vinyl acetate (EVA) foams.

While a wide range of applications can benefit from the greater shock absorption and durability of new Hytrel® foam, manufacturers of footwear, sporting goods, consumer goods, furniture, and wire and cable jacketing are expected to be early adopters of the new solution.

“It’s no secret that brand owners such as Newton Running Company are looking for more sustainable materials and production methods to counter climate change,” said Hilary Wang, marketing manager at DuPont Mobility & Materials. These companies are also actively seeking a more sustainable process than chemical foaming, which is being restricted or even phased out in some countries.

Unlike foamed materials that rely on chemical foaming agents, new Hytrel® foam is produced using CO2 and N2 gases, which are found in the time-tested, proven SCF process. This process offers three benefits:

• There are no residues from chemical foaming agents in the final products

• No VOCs are emitted, so GWP (Global Warming Potential) is reduced

• There are no odors or allergens present, and the resulting foam is skin-contact compatible

Additional fundamental properties of Hytrel® foam include:

• Up to 15% greater resilience than TPU foam (up to 80% resilience vs. 65% for TPU foam)

• Density 0.10-0.16 g/cm3 (up to 20% lighter than EVA, and more durable)

• Hardness 30-45 Shore C (10 points higher than expanded TPU)

DuPont Mobility & Materials will showcase new Hytrel® foam and other cutting-edge solutions and technology innovations in Hall 6, Stand C43 at the upcoming K 2022, the world’s leading trade fair for the plastics and rubber industry. This international event, held once every three years, takes place from 19 to 26 October in Düsseldorf, Germany.

About DuPont Mobility & Materials

DuPont Mobility & Materials (M&M) delivers a broad range of technology-based products and solutions to the automotive, electronics, industrial, consumer, medical, photovoltaic and telecom markets. DuPont M&M partners with customers to drive innovation by utilizing its expertise and knowledge in polymer and materials science. DuPont M&M works with customers throughout the value chain to enable material systems solutions for demanding applications and environments. For additional information about DuPont Mobility & Materials, visit www.dupont.com/mobility.

DuPont (NYSE: DD) is a global innovation leader with technology-based materials and solutions that help transform industries and everyday life. Our employees apply diverse science and expertise to help customers advance their best ideas and deliver essential innovations in key markets including electronics, transportation, construction, water, healthcare and worker safety. More information about the company, its businesses and solutions can be found at www.dupont.com. Investors can access information included on the Investor Relations section of the website at investors.dupont.com.