New DuPont™ eCool Technology Delivers Performance and Sustainability for EV Cooling Lines

Innovative multilayer construction offers significantly improved design freedom and lower Global Warming Potential for xEV cooling lines

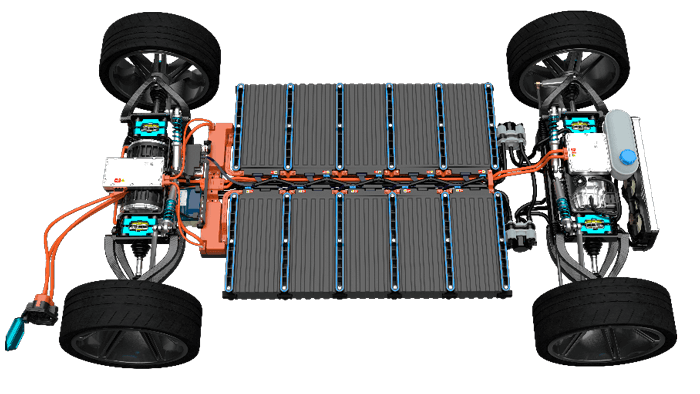

GENEVA, Switzerland, June 15, 2022 – DuPont Mobility & Materials today introduced new eCool technology for extrusion of multilayer cooling lines positioned inside and outside the high voltage battery pack. This solution addresses the challenge posed by increased cooling line requirements in xEVs, a direct result of the vital need to manage heat and energy for maximum battery operation, safety, and range.

“Automotive cooling lines are critical to maintaining the performance of EV batteries. And as a large application, they are an important target for sustainability improvement. With our eCool solution, we offer the industry a high-performance, flexible, and more sustainable solution that is also cost competitive,” said Laurent Lefebvre, global marketing director, Automotive, DuPont Mobility & Materials.

Electric vehicles can require up to three times the length of cooling lines found in ICE systems. For these large components, engineers are challenged with finding a more sustainable solution that will still hold up to cooling fluids. DuPont™ eCool technology, based on the company’s Zytel® LCPA Long Chain Polyamide grades co-extruded with thermoplastic olefin elastomer, presents an attractive alternative to current, heavier options such as thick EPDM rubber hoses and other thermoplastic assemblies. The eCool solution not only removes weight but also better resists a wide range of EV cooling fluids while remaining cost competitive. In addition, DuPont has assessed that its eCool solution can significantly reduce Global Warming Potential (GWP) of these cooling tubes by over half compared to monolayer PA12 tubes.

This new eCool technology can be easily processed via extrusion and thermoforming, and offers:

• Lightweighting: Weight reduction versus thicker EPDM rubber hose reinforced with textiles

• Sustainability: Lower GWP (Global Warming Potential) than some alternative flexible polyamide thermoplastics

• Coolant/Hydrolysis Resistance: Barrier and stress resistance to coolant chemistries

• Customization: Ability to test and customize solutions at DuPont Automotive Electrification Centers of Excellence

• Cost: Cost-effective solution for cooling lines for EVs

• Design Freedom: Positioning of thermoplastic olefin elastomer layer can be customized to improve the flexibility of tubes/pipes

Production-level support for eCool technology is available at DuPont’s Center of Excellence in Geneva, as well as at other application development centers throughout the globe. This includes advanced CAE/FEA simulation, extrusion trials, support for post-processing, welding and testing for burst pressure, mechanical evaluation of properties before and after air and chemical aging, salt stress cracking, cold impact resistance, and bend testing. With its industrial-scale processing equipment, DuPont offers customers the ability to manufacture cooling lines under near-commercial conditions, then do the testing to dial in the process and postprocessing required.

New eCool technology is the latest in a growing line-up of advances and solutions for vehicle electrification from DuPont, including:

• DuPont™ Zytel® HTN hybrid bobbin for e-motors

• Plastic/metal hybrid cooling plate made from DuPont™ Zytel® HTN for improved durability and thermal management performance of battery cells

• DuPont™ Zytel® and DuPont™ Crastin® stable orange materials for high-voltage terminals and connectors, busbars, switches, and relays

• DuPont™ Zytel® and Zytel® HTN for contact with aggressive fluids and low- to high-voltage loads in various temperature and humidity conditions

• DuPont™ Crastin® HR hydrolysis stabilized PBT for switches, connectors, and electronic control units

DuPont Mobility & Materials will showcase these and other cutting-edge solutions and technology innovation in Hall 6, Stand C43 at the upcoming K 2022, the world’s leading trade fair for the plastics and rubber industry. This international event, held once every three years, takes place from 19 to 26 October in Düsseldorf, Germany.

About DuPont Mobility & Materials

DuPont Mobility & Materials (M&M) delivers a broad range of technology-based products and solutions to the automotive, electronics, industrial, consumer, medical, photovoltaic and telecom markets. DuPont M&M partners with customers to drive innovation by utilizing its expertise and knowledge in polymer and materials science. DuPont M&M works with customers throughout the value chain to enable material systems solutions for demanding applications and environments. For additional information about DuPont Mobility & Materials, visit www.dupont.com/mobility.

DuPont (NYSE: DD) is a global innovation leader with technology-based materials and solutions that help transform industries and everyday life. Our employees apply diverse science and expertise to help customers advance their best ideas and deliver essential innovations in key markets including electronics, transportation, construction, water, healthcare and worker safety. More information about the company, its businesses and solutions can be found at www.dupont.com. Investors can access information included on the Investor Relations section of the website at investors.dupont.com.