LIN CHENG: The Automation Trend of Rubber and Silicone Injection Molding Machines

For more than four decades Lin Cheng Technologies has shown its great expertise around the world on creating exclusive services for customers. We stand out in the field for manufacturing rubber injection molding machines, silicon rubber injection molding, vacuum compression molding, thermoforming, thermosetting, carbon fiber molding, powder forming and other types of compression molding machines. The way Lin Cheng pursues its goals is to create automated functions , minimize labor requirements, energy-saving and a much better quality to customers.

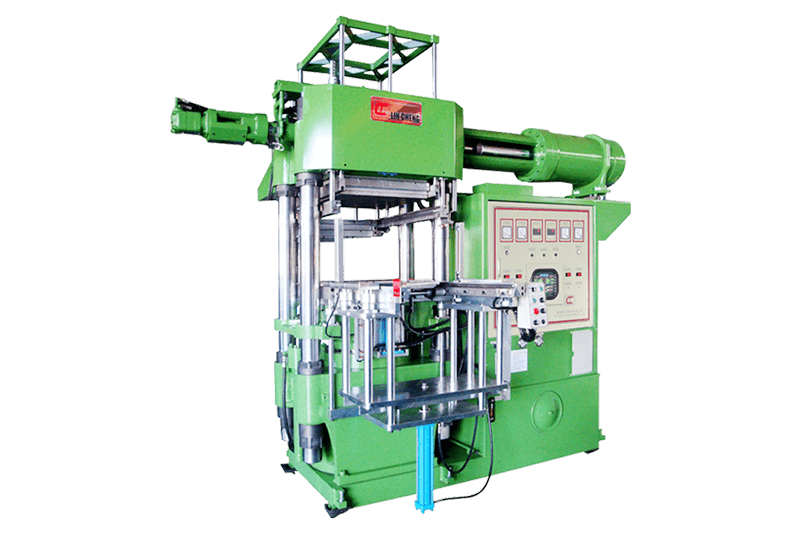

2RT Mold-Open None Runner-Waste Rubber Injection Molding Machine

As we head into the third year of dealing with COVID-19, labor-saving, material energy-saving and automation have all become indispensable advantages. The biggest advantage of Lincheng in 2022 is to improve the efficiency of production by upgrading the functional design of each machine. Among them, the upgrade of "automation" and the development of technology can effectively solve the problem of labor shortage during an epidemic. These upgrades incorporate: Cold-runner injection solution, Auto loading, Auto mold cleaning, Auto material arrange, Auto demoulding, Auto discharging, Auto fetching and other features...

The repeated changes during epidemic have made the rubber industry a with constant changes, and the cost of raw materials has risen exponentially throughout the year, causing Lincheng to fall into an unprecedented predicament.

On a positive note, however, it gradually lifting lockdowns, Lincheng continued to pay attention to the changes in industry and consumer needs, and decided to boost our professional knowledge and technical fields and development to improve efficiency and machinery. Also emphasize in quality, so that customers have higher performance and high efficiency in production. Nevertheless since Lin Cheng has mastered every step needed to follow the automation trend, the expectation for the upcoming year 2022 is to keep providing more diversification machinery models to our customers.

It’s important to highlight that Lin Cheng has stood out in different regions, such as Europe, American countries, Southeast Asia and Japan, resulting in acquiring a good reputation. Strategically, we are not currently planning on any expansion since our goal is to keep strengthening the actual markets.

CE Certificate Rubber Back-Injection Molding Machine

We are sure that in the second half of 2022, we will provide better technical services and promote our high-quality products to all over the world, so that domestic and foreign markets have enough confidence in Lincheng.

We not only provide high-quality and high-reliability machinery but also provide one-stop service for customers, including specification discussions and design, quality pre-sales and after-sales service guaranties, and operation guide. If you are interested in getting in touch and knowing more about what Lin Cheng’s has to offer for the Automated Rubber Silicone Injection Molding Machinery, do not hesitate to visit their website through the links below.

Lin Cheng Technologies Co., Ltd. established in 1978 is a powerful rubber molding machine manufacturer and occupies a space of up to 5000 pings. A strong team works with Lin Cheng, which consists of Sales, Engineering, Management, Production, Electrical Engineering, Quality Control, Research and Development and Maintenance Divisions.

We stand out in the field for manufacturing rubber injection molding, silicon rubber injection molding, vacuum compression molding, thermoforming, thermosetting, carbon fiber molding, powder forming and other types of compression molding machines.