LATEST UPDATE Subscribe Now

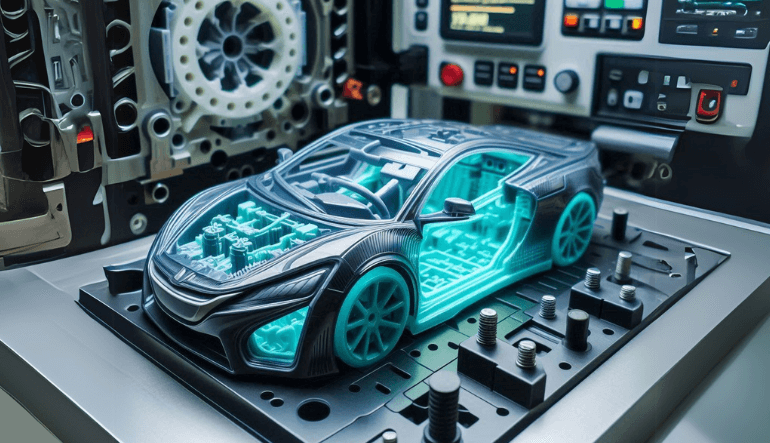

Insert Molding vs. Overmolding: Key Differences & Applications

In the field of plastic product manufacturing, Insert Molding and Overmolding Molding are two widely used techniques, each serving different purposes. Understanding their differences is crucial for selecting the right manufacturing process, especially in OEM car parts, consumer electronics, and medical devices.

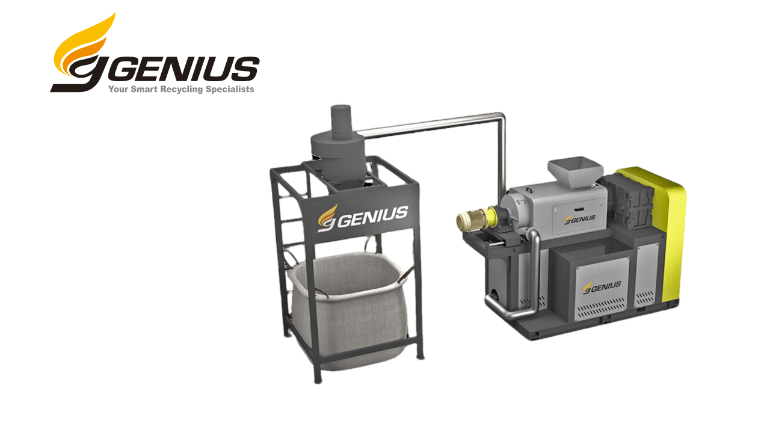

How Screw Press Dewatering Machines Revolutionize Plastic Film Recycling | GENIUS

Plastic waste has become a major environmental challenge, particularly with the growing use of plastic films in agriculture, packaging, and various industries. Recycling plastic films such as agricultural film and stretch film requires efficient dewatering to improve material quality and reduce waste.

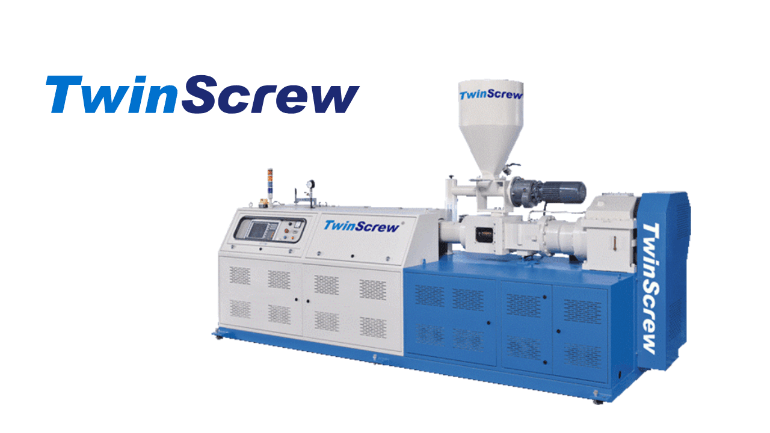

Medical Tube Extrusion Line : Key Insights and Case Studies | Twin Screw

In medical manufacturing, precision, efficiency, and reliability are critical to producing life-saving devices. PVC Medical Tube Extrusion Lines play a pivotal role in manufacturing essential products like IV lines, catheters, and respiratory tubes.

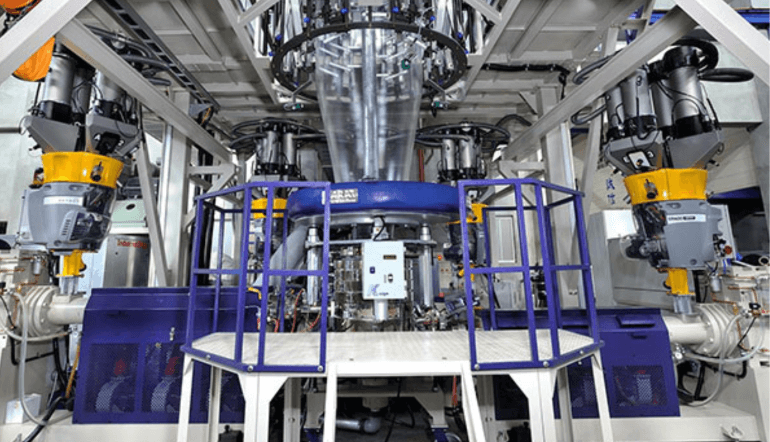

Optimizing Multilayer Blown Film : Key Factors & Advanced Machinery

Blown film technology has undergone significant advancements in recent years, resulting in the development of innovative multilayer blown film designs. These designs offer superior performance in terms of barrier properties, strength, and diversity compared to traditional monolayer films. However, achieving optimal performance requires careful consideration of several key factors during the design process. In this article, we'll explore the key considerations for optimal performance of innovative multilayer blown film designs.

Jumbo Steel: Leading the Next Generation of Straw Manufacturing

Jumbo Steel leads in straw-making machines, offering biodegradable straw solutions and tailored production equipment. Explore sustainable and efficient straw manufacturing technology today!

Leading the Way in Customized Extrusion Solutions: Sino-Alloy’s Highlight at K Show

For the first feature of the new year, we have an exclusive interview with Sino-Alloy Machinery, a company that has gained domestic and international attention in the extrusion field for its excellent technology and rich development experience. We discovered that Sino-Alloy's recent innovations align perfectly with the 2025 K Show theme and meet the latest industry trends.

JANDI'S : THE BRILLIANT EASY WAY OF BAG MAKING

Tackle modern production challenges with JANDI's JIT system for bag-making. Streamline blown film, printing, and bag-making processes while reducing waste, cutting costs, and supporting sustainability. Discover how automation transforms your bag-making operations!

Looking for a High-Value Recycling Machine for 2025? Discover How the Repro-Flex Meets All Your Needs!

POLYSTAR’s Repro-Flex recycling machine produces high-quality, hole-free pellets. Unlike other systems, POLYSTAR’s technology delivers smooth, uniform pellets that enhance the strength and appearance of plastic films. These pellets ensure scratch-free, durable, and visually appealing products.

OEM with Italy Manufacturer for Better 3-layer Co-Extrusion Film Quality

Chyi Yang showed one set 3-Layer Co-Extrusion Blown Film Machine in 2014 Taipeiplas exhibition. We cooperated with Italy SYCRO to produce main parts including IBC, 3-layer co-extrusion die, air ring, automatic width & thickness controller. The internal bubble control (IBC) is available for film cooling & increasing output. Film width is set up by touch screen instead of manual operation. According to the oil price increases & not stable, Chyi Yang uses Automatic Thickness & Width Control to control the difference range between ±5% to save resin cost. The air ring is up-and-down moveable in order to improve the cooling when you run high speed. There are 48 points in air ring to adjust the thickness automatically. The extruders are 65mm & 90mm & 65mm, equipped with motor 75HP & 100HP & 75HP. The max. film width is 1500mm & the capacity is max. 8.4tons per day.

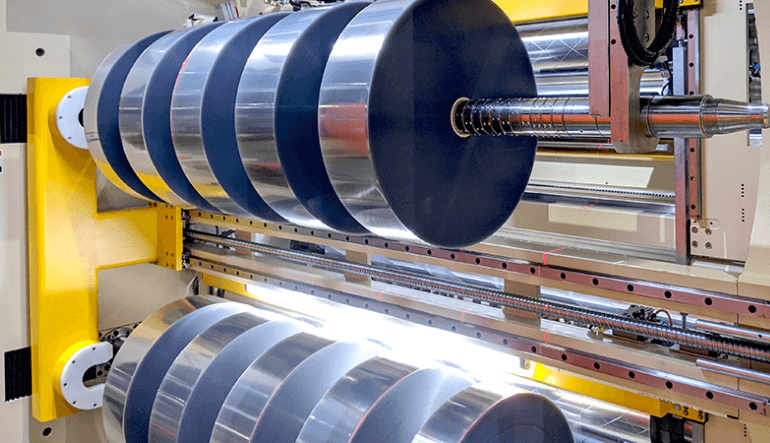

Flexible Packaging Film Slitting : Understanding Process and Select the Right Slitter

Flexible packaging is fundamental in providing protection and enhancing the visual appeal of consumer products. Central to the operations of this industry is the slitting process for flexible plastic films—which is a mechanism that significantly influences the efficiency and quality of the output.

Why KaoLu Proportional Valves Stand Out in Performance and Precision

An efficient fluid pressure and flow control system is key to ensuring the optimal performance and longevity of machinery. KaoLu's proportional pressure and flow control valves have emerged as a leading solution in the market, combining precision, durability, and energy efficiency. These valves are perfectly suited for applications requiring dynamic, rapid, and precise pressure and flow control.

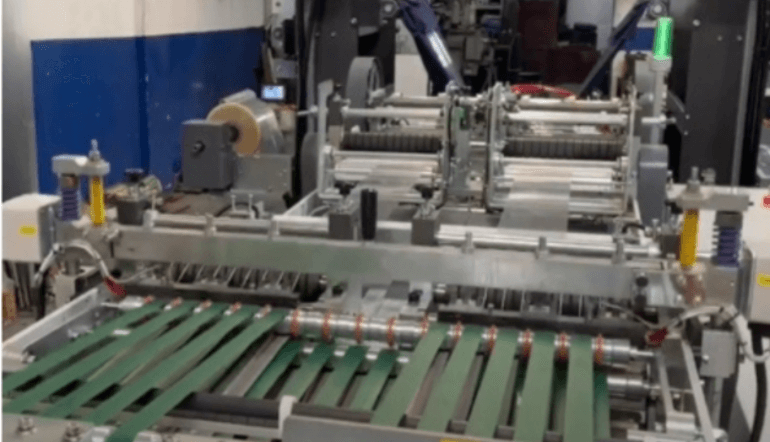

Plastic Bag Folding, Sealing & Cutting Combo Machine : Boost Your Efficiency with This All-in-One Solution

At World Steel Machinery, we understand that innovation drives success in the manufacturing industry. Our Plastic Bag Folding, Sealing & Cutting Combo Machine is an automated bag-making solution designed to streamline production by integrating plastic film folding, sealing, and cutting into one efficient system. This multi-functional packaging machine ensures faster, more efficient bag production, helping businesses reduce costs and increase output.