Which Molding Machine is Best for Your Project?

The process to make rubber and silicone products is including materials preparation, mastication, mixing, preformer, cutting, calendaring, vulcanization and machining step. Each step needs specific equipment and technology to complete.

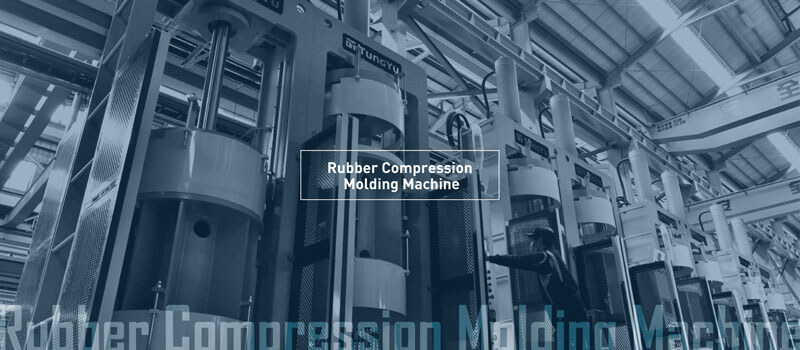

TungYu provide machines with the best control on temperature and pressure which is the critical parameter in curing process. The frame design could be divided into Compression Machine, Injection Machine and Continuous Vulcanization Machine.

As to the needs from varied molding products, TungYu apply total solutions in the material feeding, clamping, moving and demolding design. For simple product with big volume requirement, the compression machine could be the choice of speed and quality in production.

Strength and heat are the main technologies for rubber and silicone vulcanizing. TungYu serves you by various and diverse compression molding machines. We support you the most suitable solution for your need.

Compression molding machines are applied to make rubber gaskets, rubber sheets, water pipes, capacitor’s seals, tennis balls, golf balls, yoga mats, vehicle engine hoods and so on.

Compression molding machines are designed with the Finite Element Analysis and Thermal Fluid Analysis to ensure the safe and smooth production. In addition to this, Tung Yu integrates physical and cyber parts for intelligent production optimizing. We exert ourselves for the best solution and thinking ahead for you.

How to save material and increase productivity simultaneously? Using injection molding machine for rubber or silicone products to helpfully decrease material wasting and automation optimizing.

Injection molding machines are used to make all kind of oil seals, dust seals, o-rings, shaft seals, car window seals, medical syringe pistons, diving mask, and so on. TungYu focuses on compression and injection molding solutions and possesses experience and a superior team.

TungYu keep innovation on the technology for rubber and silicone injection molding solutions and help our customer to find the way and cut the edge.

In addition to this, TungYu integrates physical and cyber parts for intelligent production optimizing. TungYu and our team make our effort to serve the best solution.

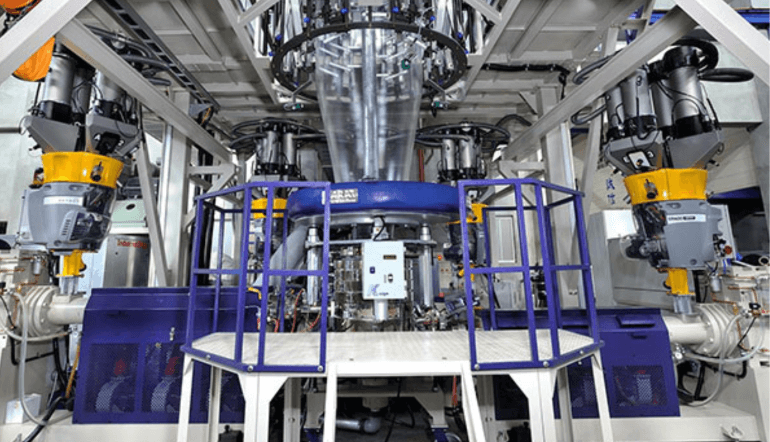

TungYu called vulcanization for rubber parts compression forming process, like the large rubber conveyor belt production process requires uninterrupted compression and heating to support continued curing.

TungYu self-develop and manufacture the unique production tools called it ROTOCURE and Bridge Type Vulcanization Machine which can meet this application.TungYu possess a lot of experience on mechanism designing, software programming, installation and turn-key solutions.

TungYu have confidence that you can own the exclusive competitiveness and serve the best quality parts in the market according to our design.