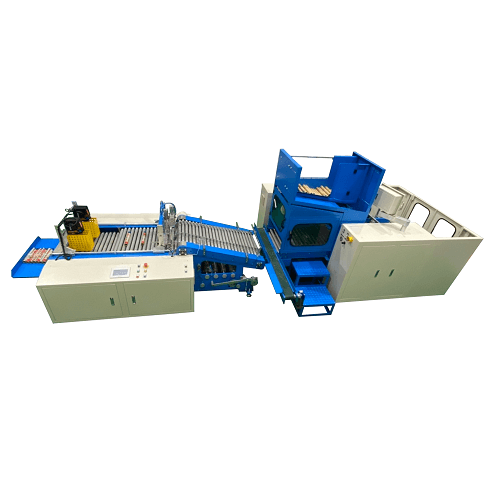

SIX-SHAFT AUTOMATIC ALUMINUM FOIL / CLING FILM REWINDER AUTOMATIC REWINDING & SHRINK FILM PACKAGING MACHINE (AH-6S + TPG50)

Categories : Slitters and Rewinders

AH-6S connected to TPG 50, the fully automatic production line, fully automatic operation system. Use a conveyor to combine two models for manufacture. Machine will automatically rewind material after input paper core. When the roll is finished and unloaded, it is carried to the packing area for automatic packing process. If the packing function is not used temporarily, TPG50 can be switched to delivery mode. Or use the conveyor which connects 2 machines to unload products from the side. This production line achieves automated manufacture. It saves time and manpower of moving materials and rolls from machine to machine. TRU-BRUTE Machinery always provides the beneficial collocation of machine for you. Welcome to consult machine with us. We will at your service.

Overload Protector

Categories : Mold Protection Devices

FUNCTION Overload Protector is equipped in Press machine to check hydraulic pressure of cylinder inside the slider. If happen overload, the hydraulic pressure of cylinder will be released immediately within 3/1000 seconds. When happen overload, in order to protect the press and die, the press will stop working immediately after receiving the signal from limit switch. After happen overload, the air will drive hydraulic pump to supply normal working pressure immediately and the press can work normal. It has pressure control valve inside of overload protector, which can adjust hydraulic pressure automatically and eliminate the impact of rising pressure (which cause by oil temperature rise) in pressing process. May select different types of components and control units base on the different types and specifications of press machines.

In-Mold Label

Categories : Films

In-Mold label (IML) is widely used in food container because the ink is between two layers of film and normally produce in dust-free fab or air conditioning clean room to minimize the human touch. Using IML can do the injection and labeling the product at the time. So it is suitable for mass production and standardization.

Megaflex-The exclusive pre-print press

Categories : Flexographic Printing Machines

Megaflex (The exclusive pre-print press) The Megaflex inline flexo printing press has an enormous print repeat capability, allowing the press to handle the widest range of pre-print corrugated box demand. If you are looking for wide web printing with the widest range of folding cartons, pre-print and board, this is the press for you to customize

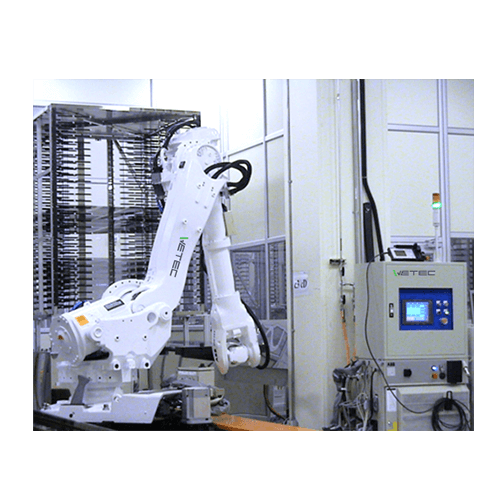

TFT-LCD Transporting System

Categories : Industrial Robots

Multi-axis robot and automation system work on line / off line with TFT-LCD production system. Multi-station unloading & loading function is applicable to quality inspection.

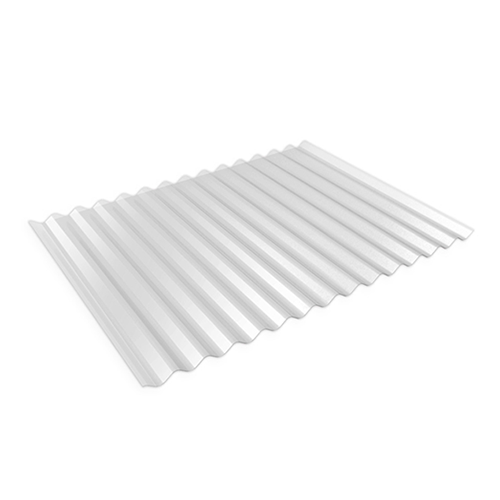

POLYCARBONATE CORRUGATED SHEET - L5

Polycarbonate Sheet (PC Sheet) is a high polymer with excellent impact resistance, transparency and light transmission. The PC sheets are widely used in factories, buildings(corridors and windows, etc.)

Batch Off Machine (Hanger Type & Net Type & Hanger Carriage Type)

Categories : Rubber Cooling Machines

This Machine For Rolls To Sheet Cooling Equipment, We Have 「Hanger Type」「Net Type」「Hanger Carriage Type」 Three Kind, The Cooling Type Have 「Water Cooling」「Fan Cooling」「Air Cooling」 Three Style, The Machine Have Three Area 「Sheet Inlet Section」「Sheet Storage Section」「Sheet Output Section」 The Sheet First Into Inlet Section Powder Water Tank To Soak, Then Into Sheet Storage Section To Hang Or Place Dry And Cooling, Then Into Sheet Output Section Automatic Cut Strip Or Pile Up To Collect, And Continuity Produce Supply Equipment The Best Automation Produce Effect.

OPTIONAL DEVICES FOR PLASTIC BLOWN FILM

Categories : Assembly Systems

FEATURES Full range of equipment will meet your machine requirement, we also provide machine parts selling individually (Die head and air ring upgrade, screen changer upgrade, winder upgrade etc.).

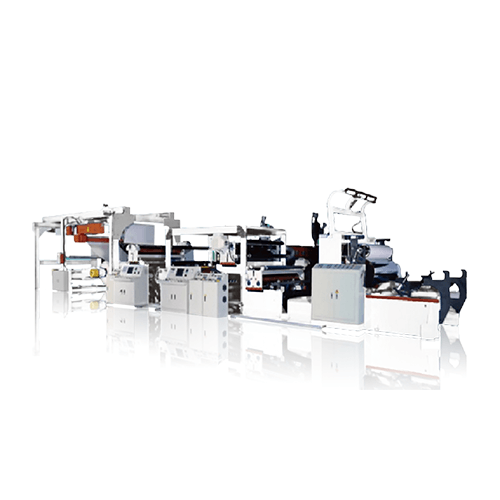

Extrusion Lamination Machine For Food Paper

● This machine is applicable for thick food type paper. ● It adopts shaftless unwinder and surface friction type winder. ● Coron treater is listed as standard equipment. ● It’s also available for setting 2 extruders as double side lamination. ● Whole machine is synchronously controlled by PLC programmable, and easily operated through human machine interface.

TH Series-850/950/1100w

Categories : Industrial Robots

‧3Asix servo drive ‧Pick up time :0.5sec,Cycle time:2.9 sec ‧Huge traverse chain ensure cable/tubing durability ‧Motor thermal design long durable life ‧Full colour touch screen controlle

POLYCARBONATE CORRUGATED SHEET - L4

Polycarbonate Sheet (PC Sheet) is a high polymer with excellent impact resistance, transparency and light transmission. The PC sheets are widely used in factories, buildings(corridors and windows, etc.)

High-accuracy Mini-sized Automatic Cutting Machine-APL-300

Categories : Foaming Machinery

●Well-designed and Stabilized Bottom Dead-point Accuracy: Specially designed machine structure and basic machining method, which provides extremely high cutting accuracy and stability. ●User Friendly Operation Interface: Digitalized parameter setting to facilitate the SOP management, while saving lengthy education and training time. ●Automatic Lubrication System: With Automatic Lubrication System, it simplifies the procedure of daily maintenance. ●Cutting Depth Adjusting Mechanism: Totally digitalized depth adjustment in achieving convenient and fast adjusting. ●Full-cut and Semi-cut Machining Effect: The cutting depth can be adjusted to the minimal 0.003mm in providing high accuracy for easier full-cut and semi-cut machining effect. ●Secondary Machining Flexibility: It is flexible for carrying out inter-station alignment cutting. ●Steel Form Cutting Flexibility: It supports steel form punching and cutting.