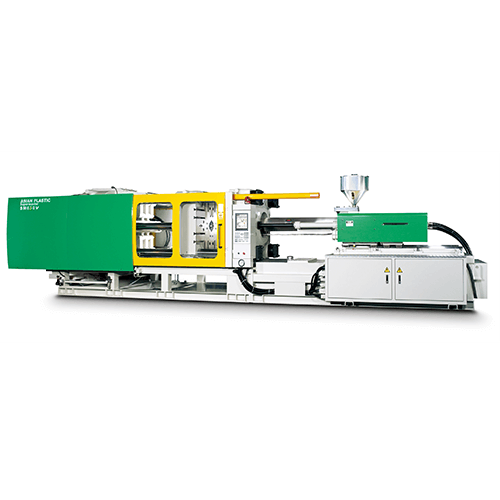

Heavy Duty Double Toggle Injection Molding Machine

Categories : Horizontal Injection Molding Machines

The new design has ensured maximum space between tie bars, as well as a large daylight area. The fixed and moving platens are designed in such a way that the yensure complete accuracy and precision. The injection carriage uses a balanced double hydraulic cylinder to provide a secure hold between the mould and the nozzle to eliminate nozzle leakage. Linear guide ways reduce mechanical friction, decrease machine wear and increases accuracy over back pressure providing better control of the injection sequence. Bosch proportional valves are equipped with LVDT positional feedback and pressure transducer. The speed of the proportional valves is more precise resulting in more accurate control.

Dual Platen Injection Molding Machine

Categories : Injection Molding Machines by Platen

As a large tonnage injection molding machine, it can saves up to 20% of the machine floor space. (foot print) • Automatic mould adjustment saves on mould-changing time.

High Speed Precision Vertical Injection Molding Machine-YQ Series

Categories : Vertical Injection Molding Machines

• Vertical four-pillar vertical clamping, with vertical injection. • The square pillar design comes with large mold size. The space within the column allows customers to install devices of automatic embedding and removing products. This allows automation for the whole machinery. • Big L / D ratio of screw, plasticizing evenly, suitable for injection molding of engineering plastics. • High standard computer control system with high precision injection pressure and high response injection speed. The quality is more stable for high-precision embedded injection molding products. • 1S single sliding: After mold opening, the lower mold will automatically slip in front of the operator for facilitating embedded molding operation. • 2S double sliding (Alternating double sliding): One mold for injection molding, another mold for taking out and putting on embedded parts operation. • 2SL double sliding (90°Alternating double sliding): One operator can operate independently. One mold for injection molding, another mold for material taking and putting on embedded parts. The two slidings are intersecting at 90 degrees, which can lower the production cost, and enhance the performance. • Able to combine automation and the high-speed injection can effectively enhance the production capacity. • A variety of circuit design (half closed servo hydraulic or high speed injection) to meet the customer’s requirements.