AUTOMATIC SHUTTLE SEALING MACHINE +VACUUM/M.A.P.-ET600

Categories : Sealing Machines

1. Sturdy construction with stainless steel cover 2. Vacuum with Gas Flushing /Gas Flushing funciton selection

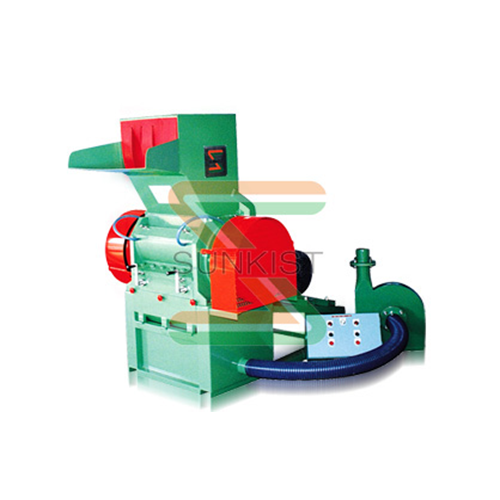

H Type Chipping Machine

Categories : Foaming Machinery

For chipping all kinds PU foam waste and quilting mattress cover waste. The SA-4A chipping machine is suitable for chipping all kinds of flexible PU foam waste, such as hr molding as well as the material waste from foam quilting mattress cover. The machine consists of rotary and stationary cutter with a water cooling system built inside the machine and also with an additional powerful fan blower, blowing the foam chips out of the machine into the silo or storage room. The particle size can be changed by changing the net mesh.

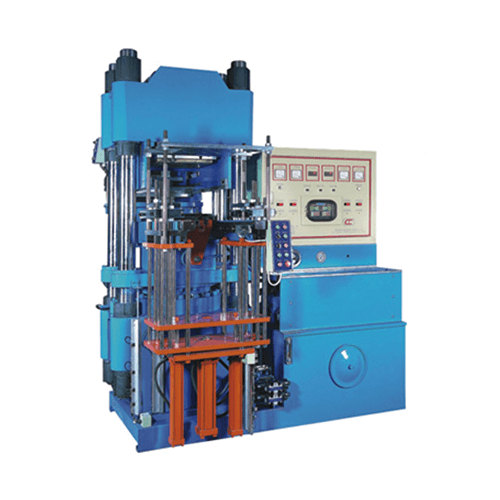

3RT Mold-Open Rubber/Silicon Continuous Transfer Injection Molding Machine-TCC-S3

Categories : Compression Molding Machines

●Nature rubber ●Rubber of metal boned parts ●Oil resistance rubber ●NBR+PVC concoction ●Synthetic rubber ●Medical/Pharmaceutical usage rubber ●Heat resistance rubber

Auto Laminating Machine ALM-800

Categories : Cutting Machines

Synchronized automatic glass handling mechanism to speed up operational efficiency. Unique, special, patented pattern film laminating mechanism, to ensure no air bubbles after lamination process. Automatic cutting and partitioning mechanism to cut and partition laminated work pieces. Laminating length and speed can be programmed and adjusted to suit actual requirements. Optional single-side or double-side protective films can be laminated to suit actual requirements. With pattern paper recoil function to automatically recoil the pattern paper. Compatible with glass automatic feeding and automatic material take-up system.

JS Series-Double Station

Categories : Automatic Blow Molding Machines

●Hydraulic type Plastic Blow Molding Machine. ●Automatic production design. ●Mold Open/Close/Move by cylinder. ●Gearbox drive extruder system. ●PLC control with Touch Screen for function, time, pressure...etc. ●Diversified parison knifes and multihead choices depend on the requirement. ●Proportional pressure hydraulic system. ●Especially for 2 liter bottle and 5 liter bottle.

KW-F2 SEMI-AUTO CAPSULE FILLING MACHINE

Categories : Capsule / Tablet Packaging Machines

KW will further improve the design of the original machine type vertical semi-automatic capsule filling machine KW-F2 to introduce the improved horizontal type of semi-automatic capsule filling machine

Mold Flip Device For Press

Categories : Mold Changing Systems

Mold Flip device using electric hydraulic motor, move up-down and flip mold through hydraulic power. Using the Mold Flip device can raise work efficiency and also reach zero accident happens. If power shut during mold flip, each hydraulic circuit is designed with the function of checking and avoiding oil leakage and the device will stop at the final stage. Shorten the operation time of mold repair. Mold Flip device helps the die to be flip. It has the inspection function of die loading and die mov-in position.

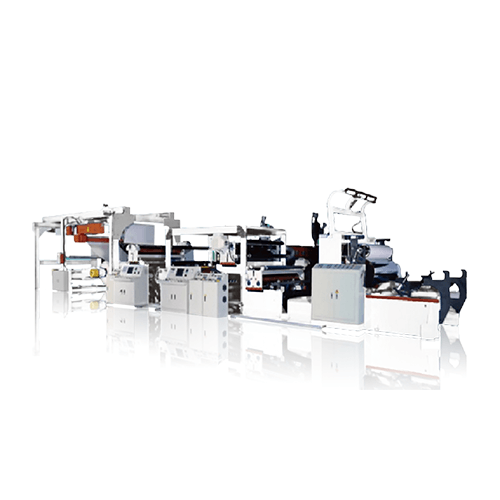

Extrusion Lamination Machine For Food Paper

● This machine is applicable for thick food type paper. ● It adopts shaftless unwinder and surface friction type winder. ● Coron treater is listed as standard equipment. ● It’s also available for setting 2 extruders as double side lamination. ● Whole machine is synchronously controlled by PLC programmable, and easily operated through human machine interface.

Induction Motor

Categories : Motors

2IK / 3IK / 4IK / 5IK 【IK Type-K Series】 AC induction motor is the suitable model for operating continuously in one direction. AC induction motors come in 6W up to 150W and can choose a gear box with a parallel shaft to reducer the output speed and increase the toruqe. AC induction motors are classified into single-phase motors or three-phase motors, which are simple and easy to install. AC induction motors can be installed in conveyor system, packaging machines, food machines, pharmaceutical machines, automated machinery, and other equipment. You can also choose motors certified by UL or CE standards.

Primary Packaging-General Filling-AF-80S

AF-80S liquid filling equipment common application is for above 60mL high viscosity liquid products such as shampoo, honey etc. The filling procedure applies piston filling method with pneumatic check valves and nozzles to minimize liquid leaking after filling procedure is completed.

PET Stretch Blow Molding Machine - TEM06M1

Categories : Automatic Blow Molding Machines

FEATURE Adopt the touch screen control system with 64K color and friendly PLC operation. Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system. The preforms are automaticalFEATURE Adopt the touch screen control system with 64K color and friendly PLC operation. Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system. The preforms are automatically arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste. Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly. The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating. Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method. With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems. Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp. The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution. Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.ly arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste. Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly. The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating. Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method. With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems. Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp. The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution. Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.