Single Layer Extruder is a commonly used type which HSIN LONG has rich manufacturing experiences. It is available for customers to choose the suitable collocation of components to meet their requirements. In addition, it allows to add recycled materials for saving the cost. There is a wide range of the application for HDPE and LDPE film products which applied with this Die Head in our daily life. Despite there are lots of advantages in other types of Die Head, Single Layer Extruder is still a great choice for use of many applications.

Plastic Film Blowing Machine is used to make the raw materials into the plastic film. Putting the raw material into the hopper, the material presents a granular type at first. When the extrusion starts working, the drive system prompts the screw to start whirling. In order to let raw material melt and mix completely, the heater which installed along the barrel with the electric control is available to adjust its temperature. Also, the air ring device will drop the temperature down and keep the air bubble with a stable situation in case of an overheat situation happen. By the pressure extruding, all the components will be pushed forward to the filter. Cleaning the impurities out, the molten polymer is then forced into the Extrusion Die Head where the film comes out and shapes like an air bubble. The temperature keeps heat at this part until film arrives at the air ring to cool down.

- Customized services for blown film machine with different film width

- Easy operation

- Use immediately without assembling

- Hopper

The feeding system which stores the raw materials inside before entering the barrel for next processing. It mainly stores the unused polymer before the device start working. (Available to option the Hopper/Dosing Hopper and choose the material of it.)

- Screw & barrel

The raw material will be completely mixing through the interaction of screw and barrel. Squeezing and pressurizing by them, the molten material be transported to the Extruder Filter for next process. (Choosing the suitable design for different materials.)

- Extruder Filter

Keeping the impurity out from the film which includes the pollution and molten material such as metal, wood and paper. Bringing the clean film without impurity and improves the quality of film as well. (Available to choose the Extruder Filter, Manual Screen Changer and Durable Screen Changer.)

- Adapter

To connect the barrel and the filter, adapter is available for different types and requirements which include L-type tube, long straight tube and short joints for different using. (Collocating various types of Adapter for different machine setting.)

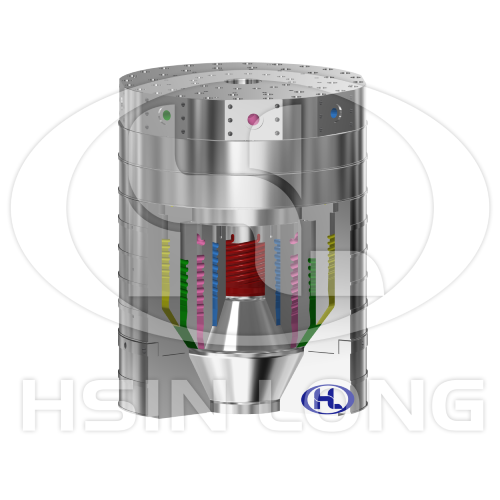

- Extrusion Die Head

The main function of Die Head is to distribute the melted polymer evenly so that the thickness measured around the circumference of the tube being produced is uniform. It is the key factor to ensure a quality film. (According the final application of products to collocate HDPE&LDPE Single Layer / ABA / ABC / Multi-Layers Extrusion Die Head.)

- Air Ring

Blown Film Air Ring used to cool down the temperature of molten material and stabilize air bubble. Besides, with the installation of IBC system can increase the overall capacity as well. (Available to adjust the size of air bubble and the height of cooling wire.)

Model |

HL45 EXTRUDER |

HL55 EXTRUDER |

HL65 EXTRUDER |

| a) Material To Be Used: | HDPE/LDPE/LLDPE | HDPE/LDPE/LLDPE | HDPE/LDPE/LLDPE |

| b) Layflat Film Width: | MAX:550mm | MAX:900mm | MAX:1100mm |

| c) Extrusion Output: | MAX:38~45Kg/Hr | MAX:60~80Kg/Hr | MAX:120~140Kg/Hr |

| d) Film Thickness: |

HDPE

0.015mm~0.15mm LDPE: 0.02-0.2mm |

HDPE

0.015mm~0.15mm LDPE: 0.02-0.2mm |

HDPE

0.015mm~0.15mm LDPE: 0.02-0.2mm |

|

|

EXTRUDER |

||

| a) Screw Dia.: | 45mm, L/D=30:1 | 55mm, L/D=30:1 | 65mm, L/D=30:1 |

| b) Gear Box: | 20HP | 30HP | 50HP |

| c) Driving Motor: | 20HP | 30HP | 50HP |

| d) Air Cooling Fan: | 2pcs | 3pcs | 4pcs |

EXTRUSION DIE & COOLING EQUIPMENT |

|||

| a) Die Head: | HDPE50~80mm | HDPE90~120mm | HDPE150~180mm |

| c) Filter: | 45mm | 55mm | 65mm |

| d) Air Blower: | 3HP | 5HP | 7.5HP |

|

|

CONTROL PANEL |

||

| a) Type: | Individual Box | Individual Box | Individual Box |

| b) Heating Zone: | 5 Point Temperature Control | 6 Point Temperature Control | 7 Point Temperature Control |