LATEST UPDATE

Three Systems for Thermoforming Machines - CHUDONG | CHINAPLAS 2021

PRM Media Channel continues with this great cooperation we began with CPRJ, the official media group of CHINAPLAS, providing insights about Taiwanese experts in the Plastic and Rubber Industry. In this specific case, we had the great opportunity to interview one of our special actors in the Thermoforming Machinery Industry who will give us some great insights into the related industry. CHUDONG Machinery is a professional manufacturer with more than 35 years of experience in manufacturing & developing thermoforming technology and services in forming, cutting, and stacking in one place. The core for growth and success according to CHUDONG is having a strong R&D that can create specific systems for different markets. In this video, our PRM Director Alice will be carrying this interview with President Chester Chen & Vice-President Sophie Lu from CHUDONG Machinery Company. In the following President Chester Chen & V.P. Sophie Lu will be covering more about the three systems for air pressure thermoforming machines for the European, Japanese, and Asian markets: 1. Three Systems for Thermoforming Machines 2. Key Factors for Product Development 3. Differences between these Three Thermoforming Machine Systems 4. 2021 Innovations and Developments 5. CHINAPLAS Exhibition 2021

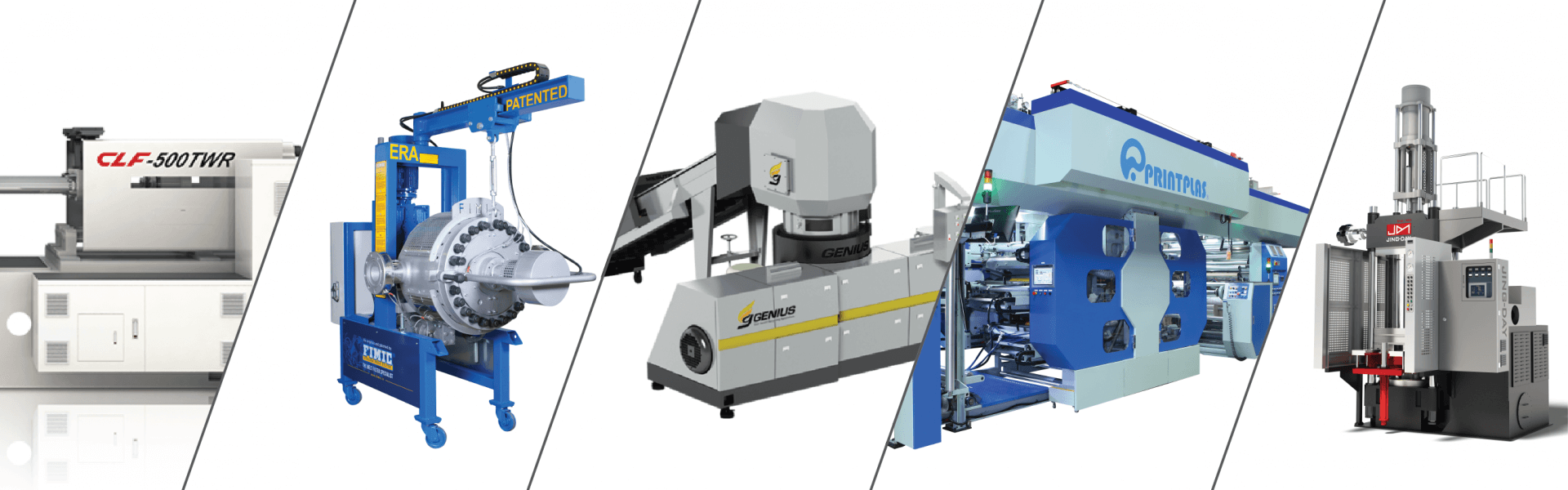

Plastic Continuous Thermoforming Machine - Automatic Cup Lids Machine | CHUDONG

Continuous Plastic Thermoforming Machine For Cup Lids | SL-1220A from CHUDONG MACHINERY High-rigidity design of machine bed: Integral casting design combined with high-tension steel plate structure offers steady and low noise operation. 4-column high-rigidity guide-rod mechanism: Guide-rods are made of top-grade steel, offering high repetitivity of mold clamping in combination with the 4-column mold structure for steady forming. Servo chain feeding system: Japanese chain operated by servo-controller ensures exact precision of high-speed feeding. Precision Temperature Control System: Independent temperature control with the respective settings for each temperature zone uses SSR with PID calculus for controlling the temperature, combined with high-speed transmission and control, offers precision adjustment, and is convenient for elevated yield. Upper and Lower Heating Oven: German-made ceramic heater, temperature accuracy can be controlled very well. Automatic Lubrication System: Automatic oil feed for slide parts, eliminating any failure resulting from insufficient lubrication. Applications: Disposable Sushi box, egg tray, Various types of lids, Cooked food coverings, Strawberry box, Salad box, Plastic containers, Transparent salad containers, Fruit box, Vegetable box, Fresh fruit packaging, All types of food packaging, Takeout box, Instant noodle bowl, Lunch box, and so on

Plastic Thermoforming Machine - Fruit Container Box Machine | CHUDONG

Plastic Thermoforming Machine for Fruit Container Box - RMD 800from CHUDONG MACHINERY European design, intelligent control, lightweight. Convenient mold change, quick, suitable for smaller quantities and diverse production line manufacturing. High rate of movement, low failure rate, reducing the costs associated with machine errors. Innovative intelligent system, which gives the operator an easy to use interactive interface which reduces the opportunity for human error. Remote obstacle monitoring and instantaneous data processing allow rapid problem correction. High-precision cutting technology, allowing high-speed control, low machinery wear, and exceptional cutting performance. Adjustable, automatic stacking technology, which remembers your last production needs. Applications: Disposable Sushi box, egg tray, Various types of lids, Cooked food coverings, Strawberry box, Salad box, Plastic containers, Transparent salad containers, Fruit box, Vegetable box, Fresh fruit packaging, All types of food packaging, Takeout box, Instant noodle bowl, Lunch box, and so on