Plastics & Rubber Machinery Videos

With PRM professional matching services, we labeled 15 Machinery Categories and more than 600 videos, for you to conveniently find a supplier that best suits your business.

ALL STYLES

AUXILIARY EQUIPMENT AND INTEGRATED AUTOMATION

BLOW MOLDING MACHINES

EXTRUDERS AND EXTRUSION LINES

FINISHED/SEMI-FINISHED PRODUCTS

INJECTION MOLDING MACHINES

MOLDS AND DIES

PACKAGING MACHINERY

PARTS AND COMPONENTS

PLASTIC CONVERTING MACHINES

PLASTIC RECYCLING & MATERIAL PROCESSING MACHINERY

PRINTING MACHINERY

RAW MATERIALS & ADDITIVES

RUBBER PROCESSING MACHINERY

SHOE MAKING MACHINERY

THERMOFORMING MACHINES

PLASCO's JC-ABA Series of 3-layer co-extrusion blown film lines are the ultimate economic and environmental solutions for multi-layer blown film production.

【Machine Spec】

Applicable Material: LDPE / LLDPE / MDPE / HDPE

Screw Diameter (mm): "45/55", "50/55", "55/75"

Film Layflat Width (mm): 800 / 1000 / 1200

Film Thickness (mm): 0.015-0.10

Extrusion Capacity (kg/hr): 100 / 160 / 250

【Application】

Express Bag

Plant Bag

Shopping Bag

T-shirt Bag

Laundry Bag

Garbage Bag

【Company Intro】 PLASCO is a global industry leader in the design, manufacture, and supply of innovative plastic extrusion lines. They specialize in applying innovative engineering concepts to the design and manufacture of plastic extrusion lines with more than 30 year experiences.

PLASCO's JC-FYB Series of extrusion lines are designed to produce either standard or heavy-duty fibrillated tape for technical end-use applications, such as baler twine, insulated cable filler, carpet backing, synthetic grass, and more!

【Machine Spec】

Applicable Materials: PP / HDPE

Screw Diameter (mm): 85 / 100 / 110

Denier (D): 3000-25000 / 3000-30000 / 3000-35000

Working Width (mm): 800 / 1000 / 1200

Extrusion Capacity (kg/hr): 120 / 200 /250

【Application】

Rope

Cable filler

Baler twine

【Company Intro】

PLASCO is a global industry leader in the design, manufacture, and supply of innovative plastic extrusion lines. They specialize in applying innovative engineering concepts to the design and manufacture of plastic extrusion lines with more than 30 year experiences.

PLASCO's JC-SPP Series of extrusion lines are designed to produce PP strapping bands, which are commonly used for light- and medium-duty applications, such as for securing newspapers and magazines, carton boxes, and pallet freight shipments.

【Machine Spec】

Applicable Material: PP

Screw Diameter (mm): 90 / 100 / 120

Strap Width (mm): 5-19 / 12-19

Extrusion Capacity (kg/hr): 180 / 250 / 380

Straps Produced: 4-2 / 8-4 / 8-6

【Application】

Newspaper strap

Carton box strap

【Company Intro】

PLASCO is a global industry leader in the design, manufacture, and supply of innovative plastic extrusion lines. They specialize in applying innovative engineering concepts to the design and manufacture of plastic extrusion lines with more than 30 year experiences.

PLASCO's JC-MNN series of extrusion lines utilize a dual-stage drawing/single-stage heating process to produce high quality PA6, PA66, PET or PP monofilament extrusion line.

【Product Spec】

Applicable Materials: PA/PET

Screw Diameter (mm): 50 / 55 / 65 / 80

Filament Diameter (mm): 0.12-1.00 / 0.12-3.50 / 0.50-3.50

Extrusion Capacity (kg/hr): 35 / 50 / 75 / 120

【Application】

Rope

Toothbrush

Longline monofilament

Fishing line

Tennis strings

Fishing net

【Company Intro】

PLASCO is a global industry leader in the design, manufacture, and supply of innovative plastic extrusion lines. They specialize in applying innovative engineering concepts to the design and manufacture of plastic extrusion lines with more than 30 year experiences.

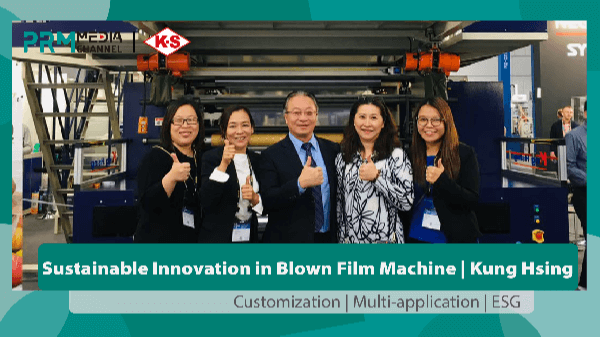

The latest innovation of Three Layer Blown Film Machine is featured with 3 in 1 Gap Winder that combines Surface Type, Contact Drive Type and Gap Winding.

We are pleased to invite Kung Hsing Machinery to share the insight of the Blow Film Industry with us, which includes application, ESG and the effect of geopolitic to the economy.

【Product Features】

● Five layers co-extrusion blown film line

● Φ300 mm Die : Production output 600 kg / hr

● Gain in weight gravimetric dosing unit ( Italy made)

● Profile measurement & auto thickness control (Auto Air Ring-Height Adjustable, High Efficiency Cooling and High Output Rate, Germany made)

● IBC computer control system (U.S.A Made)

● Horizontal oscillating take-up unit

● 3 in 1 Gap winder ( Surface type, Contact Drive Type and Gap Winding)

【Video Outline】

0:00 Welcome to K 2022

0:24 Introduction of Kung Hsing Machinery

0:53 Highlights of Kung Hsing at K 2022

1:54 Applications of KS Blown Film Machines

2:34 Upgrade of Three Layer Blown Film Machine

5:38 Strategy and Implementation to ESG

6:51 Customer Oriented Service

7:54 Advantages of Taiwanese Supply Chain

8:54 Occurrences affect Global Market

10:04 Development Trends of KS Blown Film Machine

11:07 More information on PRM B2

JANDI'S INDUSTRIAL CO., LTD. is committed to developing blown film machines combined with bag making, printing, and recycling machines. Until 2018, they obtained more than 30 patents of plastic machinery in China and Taiwan.

With the concept of plastic reduction raising, JANDI'S proposes an idea about green innovation. The company develops JIT series integrated plastic bag making machines that are 100% suitable with biodegradable and compost materials such as PBAT and PLA. Moreover, JANDI'S added the automatic packaging part to JIT series.

The extrusion line has maximum PP melting output.

Capacity is 160 ~ 520 kg/h and the unit is equipped with a screen filter changer and rotary blade slitting system.

The machine has less down time and prevents production loss.

The pressure rollers of the take-off unit are pneumatically controlled, and have synchronized control electronic system.

Available to meet special requirements.

【Company Introduction】

Hao Yu Precision Machinery Industry Co., Ltd. is a leading manufacturing of PP and PE woven bag machinery and whole-plant equipment. Since its establishment 1980, HAO YU has been dedicated to the research and development of high performance machinery.

Jumbo Steel has more than 30 years of experience in manufacturing straw making machines and straw packing machines. Moreover, Jumbo Steel is providing turnkey solutions for your business according to your needs.

【Product Lines】

HAO YU Raffia Tape Stretching Line is designed for producing PP/HDPE raffia tape and flat yarn.

【Equipment Features】

- Capacity: 160 ~ 520 kg/h

- Designed for making 500-1500 denier

- Working speed 100-270 meter/minute

- A screen filter changer

- Rotary blade slitting system

- Synchronized control electronic system

- Low energy consumption

- Less downtime

- Reduce production loss

【Additional Features】

- European-made gearbox

- T-die

- Melt pump

- Tape winder

- Designed for making 2000-6000 denier upon special request

【Finished Products】

- Woven bag

- Geotextile

- Artificial grass

- Carpet backing production

【ABOUT HAO YU】

Hao Yu has been dedicated to manufacturing PP/PE/PET woven bag machinery and whole-plant equipment since its establishment in 1980. Enhancing present machinery and developing new models are Hao Yu’s objectives in order to improve the efficiency, product quality, and profitability for their customers.

Introducing POLYSTAR Twin Head Blown Film Machine with the motto of the company: "Extrusion Made Simple". The blown film extruder is specially designed for HDPE and LDPE bag producers.

【HIGHLIGTS OF Twin Head Blown Film Machine】

- Monolayer (1 Layer)

- Two Die Heads, Single Screw

- Film Width from 150~650mm

- Extruder Dia: 45mm, 55mm, 75mm

- Material: HDPE, LDPE

- Output: 30~140 kg/hr

- Works with virgin, recycled materials, Biomaterials, and CaCO3

- Possible end products: T-shirt bags, Bottom sealed flat bags, Shopping bags, Supermarket bags, Garbage bags

【MACHINE PORTFOLIO OF POLYSTAR】

1. BLOWN FILM MACHINES

- One Layer Twin Head HDPE LDPE 650mm Machine

- Multilayer Blown Film Machines

- One Layer HDPE / LDPE 800mm (Mini type) Machine

- AB - 2 Layer Co-Extrusion LDPE/LLDPE Machine

- One Layer HDPE LDPE LLDPE 1500mm Machine

2. BAG MAKING MACHINES

- Bottom Sealing Bag Making Machines

- Folded Garbage Bags Machines

- Perforated Bag on Roll Machines

- Thick Bag Making Machines

- Laundry Bags Machines

3. RECYCLING MACHINES

- Plastic Recycling Machines

- Plastic film recycling Machines

- Two stage recycling Machines

- Air cooled recycling Machines

- Hopper feeding recycling Machines

- Shredder integrated recycling Machines

【ABOUT POLYSTAR】

POLYSTAR is a pioneer manufacturer of Plastic Recycling Machines, Blown Film Extruders, and Plastic Bag Making Machines. The company has gained the trust of its customers with 32 years of experience in the industry, today POLYSTAR has been sold over 4,000 machines in 105 countries worldwide.

Introducing Blown Film Machine from one of the pioneering blown film extruder manufacturers in Taiwan, KANG CHYAU.

For more information and/or inquiry, please directly contact the manufacturer at the link given above. For any assistance,

PRM will be more than happy to assist, please just leave a comment below. Then we will reply and contact you asap.

Machinery in the Video: HDPE LDPE LLDPE (ABA) Two Layer Blown Film Machine from KANG CHYAU MODEL: KMTL-50S

SUITABLE MATERIAL: HDPE / LDPE / LLDPE

APPLICATIONS: Car Film, Food Packaging, Courier Bag, and so on.

FILM THICKNESS: 0.010-0.15 mm

FILM WIDTH RANGE: 1200 mm

FILM OUTPUT: 90-140 kgs/hr

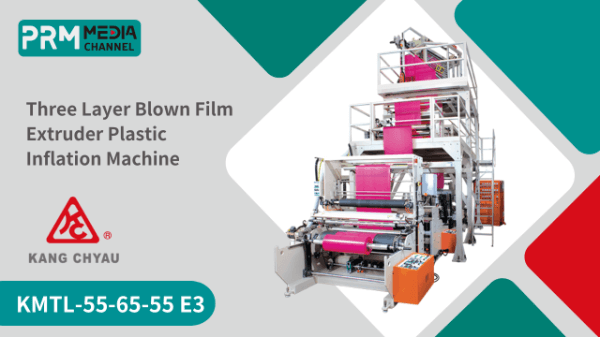

Introducing three-layer blown film extruder machine, in another name called three-layer plastic film inflation machine. From one of the pioneering blown film extruder manufacturers in Taiwan, KANG CHYAU. For more information and/or inquiry, please directly contact the manufacturer at the contact button. For any assistance, PRM will be more than happy to assist, please use CONTACT PRM button to leave a comment below. Then we will reply and contact you asap.

Machinery in the video: THREE LAYER BLOWN FILM EXTRUDER PLASTIC INFLATION MACHINE | Model No: KMTL-55-65-55 E3

Film Width: 500-1800 mm

Screw Diameter: Ø 40-45-40/45-55-45/55-56-55 mm

Suitable Materials: HDPE/LDPE/LLDPE/mLDPE