Pioneering Sustainability: Taiwan Kinki Machinery Eco-Friendly Vertical Injection Molding Machines

Toward the 1970s, the backbone of the Taiwan Miracle such as agricultural and light industrial goods exportation took some massive hits. First, the American military ceased support of the war in Vietnam, meaning Taiwan may soon lose American financial support once the US shifted their attention away from Asia to the Middle East. Second, the 1973 Oil Crisis and the later 1979 Oil Crisis further devastated the Taiwanese economy. By 1979, the government decided to support significantly heavy industry like electrical engineering and machinery manufacture, with the support and the excellent foundation of Taiwanese craftsmanship, plastic and rubbery machinery took a significant leap in the 1980s. Many well-known Taiwanese manufacturers began their business around this time, including Taiwan Kinki Machinery.

Taiwan Kinki Machinery (TKC) is a professional and experienced Taiwanese manufacturer dedicated to all kinds of vertical injection moulding machines, that service thousands of factories and enterprises across the globe, producing various equipment and consumer goods. TKC’s machines have supported their customers manufacture goods for decades, and will continuously make their business booming for the next coming decades with TKC’s innovative, expertise, and environmentally friendly machines. TKC is the first Taiwanese vertical injection moulding machinery manufacturer to propose and achieve ESG (Environmental, social, and governance) set by the UN. Now the future has come, the damages and impacts of people’s ignorance have concretised into natural disasters, devouring innocent lives and cities across the globe. Within the recent five years serval laws have been established globally to respond to the environmental crisis, making the trend of the future straightforward, the task of implementing ESG is now inevitable for everyone, a task that TKC is well prepared for years.

Environmental: Plastic And Pollution

Plastic seems to be the destroyer of the environment, the monster that polluted our lands and ocean, and the entire plastic industry seems to be the enemy of the earth. However, let’s not forget it is our systematic misusage of plastic products, taking plastics as single-use materials that cause the devastation of our environment. Moreover, according to American Chemistry Council, plastics help us protect the environment by reducing waste and lowering greenhouse gas emissions. Therefore, plastic is not our enemy but an ally to fight the environmental issue and overconsumption embedded in our society.

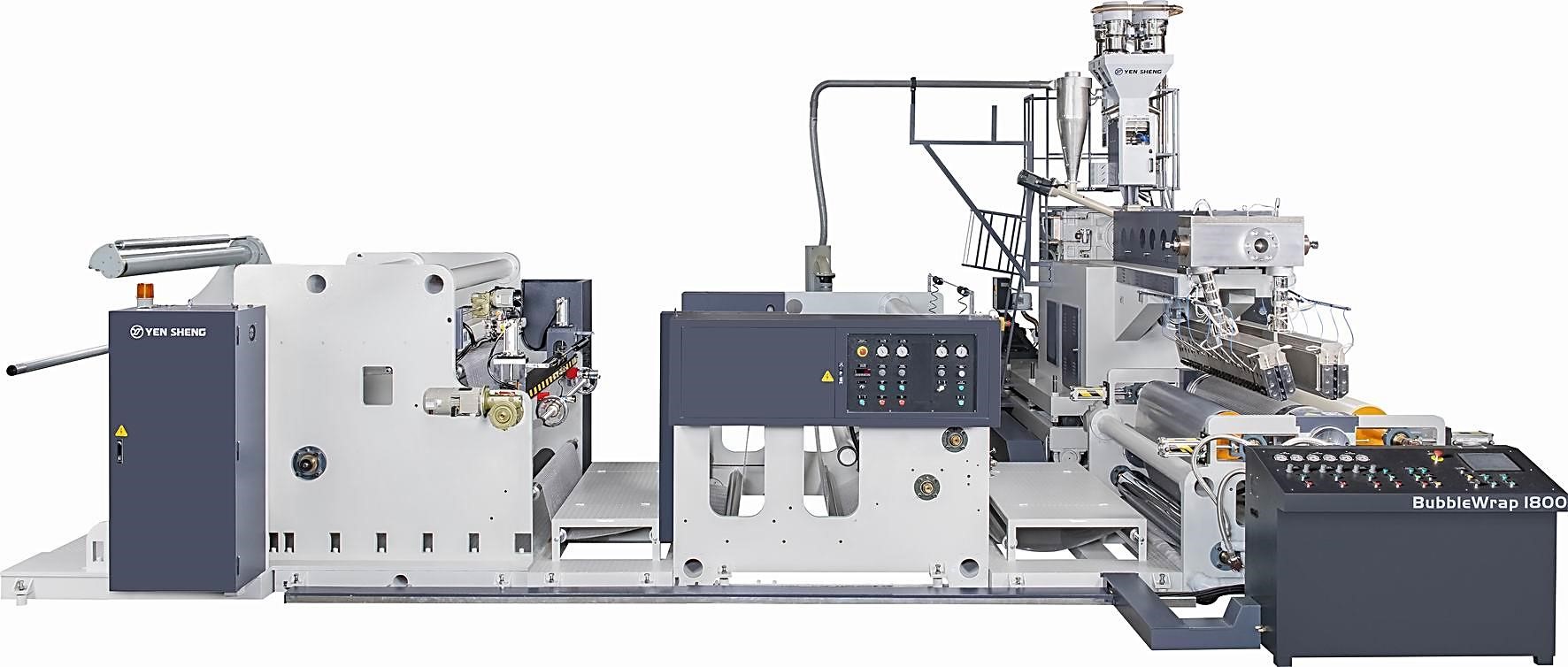

We all know that a large portion of pollution originated from the industrial production phase, the wasted materials, the oily fume and greenhouse gas emission into the air, and the secondary heat for machines are all part of the prime culprit for the environmental crisis. Thus, TKC aims to reduce the co2 emission, secondary heat, and waste of materials during the production phase. For the factory owners that have been troubled by any one of these issues or wish to reduce their pollution, TKC has developed an incredible All Electric Vertical Injection Molding Machine as a solution to resolve all three challenges. Contrary to the traditional injection machine, which will waste materials for imprecise injection and produce waste heat and oily fume that may cause deteriorating health for surrounding personnel. The TKC’s All Electric Vertical Injection Molding Machines are powered solely by electricity, which is arguably more energy-efficient and environmentally friendly, no hazardous waste would be produced during the entire procedure of production with their machine. Fulfilling not only their promise on environmental issues but also helping their customers to achieve carbon neutrality before 2035.

Social: Safe Work Environment Brings Healthy Employees

TKC has committed to building a safe, healthy, and secure environment for both employees and customers. The safety of the natural environment is crucial, but the safety of the work environment for employees and the people surrounding the factory can not be neglected. When TKC decided to reform their general policies, to achieve sustainable development and later goal of carbon neutrality, they have invested greatly not only in saving the natural environment but also set the goal of improving its work environment, minimising the possibility of accidents and ensuring a hazard-free environment for the employee. Ensuring the personnel’s health and safety is one of their top priority, TKC has further expanded their vision from securing only their employees’ health to the safety of their customers' factories.

Therefore, TKC has considered their social aims and designed its All Electric Vertical Injection Molding Machine accordingly, which is also designed to minimise all the possibility of accidents and factors that may cause long-term damages, specifically, the hazardous oily fume, oil splash, secondary heat, and noise pollution.

Governance: NO SERVICE NO BUSINESS

In the past, the TKC relies on traditional supply chain management, where the suppliers have to be within 20 kilometres and TKC have to order a large amount of stock for the best production efficiency in price and time control. However, they realised the traditional method of supply chain management would waste space for storage and drastically increase the cost of the wrong prediction of the future. For instance, the pandemic and the Russo-Ukrainian War led to a shortage of steel causing the price to go sky-high. Therefore, the reform of supply chain management is one of TKC’s focuses, they plan to gradually shift the traditional supply chain model to a digital core and AI-supported model that best fits the trend of industrial 4.0 and sustainable development.

Moreover, TKC believes in “NO SERVICE NO BUSINESS” meaning the service of everyone is just as important as the innovation of their machines, they are known for their persistence to protect the right of every employee, customer, and member of the board, ensuring that no one in the relationship with TKC will be on the losing side. This is the reason why over 70% of TKC’s employees choose to continue their careers in TKC, even after 17 years or above in this company. That’s also why over four decades of business, so many customers choose to maintain a good business relationship with TKC. In addition to their excellent service and persistence in customers’ rights, TKC’s professional advice and more importantly their privacy policy that dedicated to securing customers’ intellectual property.

A Clean Environment For Employee And The Future

As the future has come, the pressing issue of environmental and social problems requires all of us to make changes in the present business and production model, and quickly make our way to a more sustainable and socially responsible model. Despite TKC being ahead of most other manufacturers and business owners, TKC believes that there’s a lot more for them to do and improve. Their All Electric Vertical Injection Molding Machine is just the first step in helping manufacturers to catch up with the trend of sustainable development and carbon neutrality. It’s capable of reducing the waste of materials with high accuracy, and minimising the side product of hazardous oily fume, oil splash, secondary heat, and noise pollution while saving more energy than traditional injection machines. Not to mention, their NO SERVICE NO BUSINESS guarantees you the best service you deserve, TKC maintains a quick reaction team dedicated to factory service, allowing you not to pause production for a long time just for some minor repair.

TKC hope by publishing such a futural and environmentally friendly injection machine may remind the plastic industry that, the plastic industry is not against the wave of environmental friendliness, and that the plastic industry can be just eco-friendly as other industries. Their employees trust TKC to continue leading them and caring for them in the future because TKC has truly considered almost every aspect to protect everyone’s safety, health, and rights. Perhaps, you should give TKC a chance and trust them will take your business to the next level and to the future.