LATEST UPDATE Subscribe Now

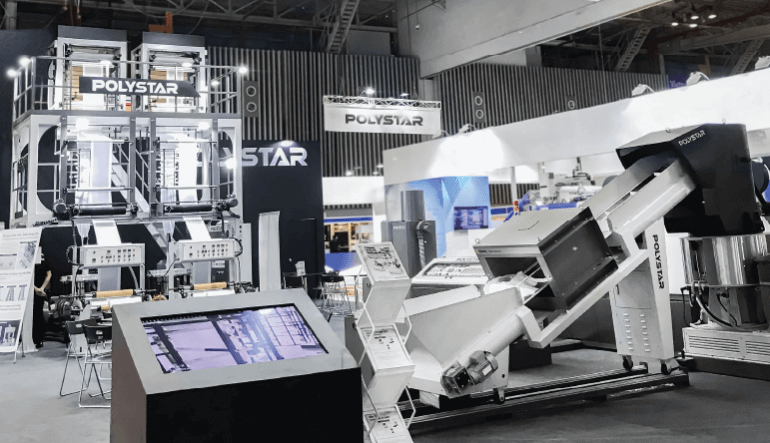

Find the Latest POLYSTAR Solutions at These Upcoming Plastic Exhibitions of the Year

Having the advantage of attending over 20 global exhibitions annually, in the last quarter of 2023, we sustain the excitement of meeting you at one of the upcoming exhibitions in your region. As a leading plastic recycling machine and blown film machine manufacturer from Taiwan, we can’t wait to share POLYSTAR solutions with you, that would make your plastic business simpler.

CHEN WAY : How to Select the Correct Blow Molding Material for Your Products

Extrusion blow molding machines can produce a wide variety of hollow plastic products. It is important to keep in mind that in order to produce exceptional products, besides purchasing high-quality Blow Molding Machines, it is also crucial to choose the correct blow molding material for each project. This ensures that the end products will have the desired properties and will also be able to withstand the environment(s) that they will be exposed to.

VietnamPlas Returned in its Largest Scale Ever with Innovations in the Plastics and Rubber Industry

Over the years, VietnamPlas has been known as a reliable trade platform where domestic and international businesses have exchanged knowledge and technical advancements in the industry and have engaged in procurement. This year, the exhibition has attracted the participation of 18,507 visitors and 625 exhibitors from 22 countries and regions.

Global plastic industry actors gather at the Plast Eurasia Istanbul

The Plast Eurasia Istanbul Fair, a significant annual exhibition for the plastic industry, will bring together market actors from November 22 to 25, 2023. The 32nd iteration of the event will take place at the Tüyap Fair and Congress Center, providing industry representatives with a comprehensive overview of the latest advancements and technologies in the plastic industry, all under one roof.

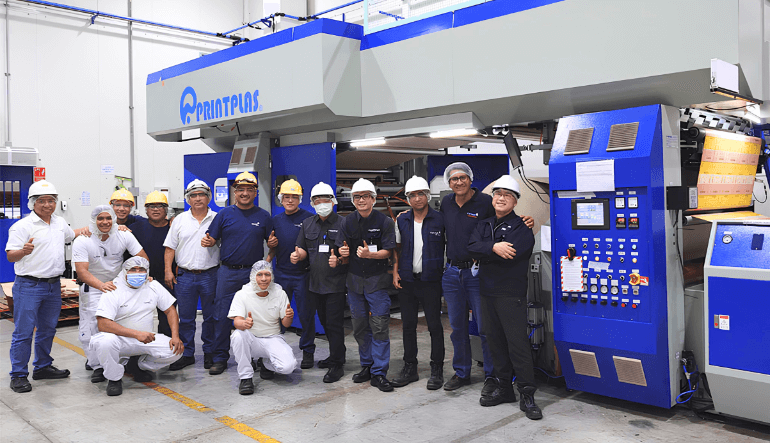

PRINTPLAS: PRECISION, NO BLUR YOUR BEST PARTNER IN PRINTING BUSINESS!

Printplas Machinery Co., Ltd have been established since 2001 and specialized on the manufacturing of CI & STACK flexographic printing machine in Taiwan. With skilled workers and machine R&D department, we are keeping our efforts to providing precise, stable, high-speed printing machines for our users.

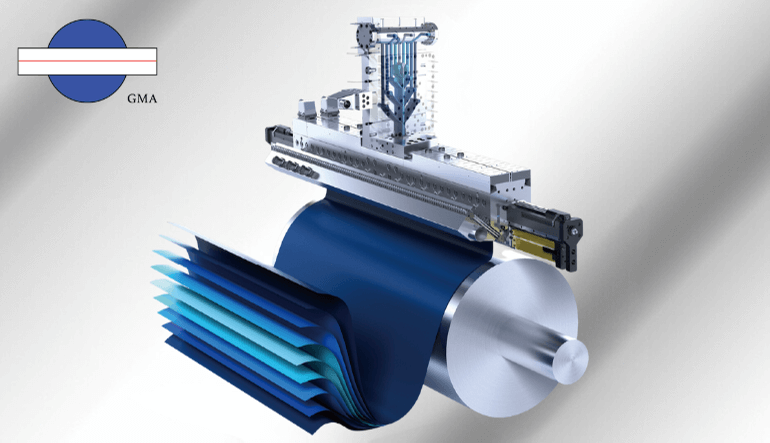

Here are 10 key points to understand extrusion dies.

This article explores extrusion dies, a vital component in the plastics industry. It focuses on "flat extrusion dies," which create uniform sheets and films by guiding polymer material through a chamber. The die's structure includes a body, width, and thickness adjustment systems. Extrusion dies find applications in various industries, from stationery boards to automotive films. The manufacturing process involves precise machining and finishing.

PRM-TAIWAN : Navigating Challenges, Uncovering Prospects: Plastic and Rubber Industry in Turkey

Turkey, nestled at the crossroads of Europe and Asia, boasts a rich cultural and historical heritage and has recently emerged as a formidable economic force in the Middle East and Eurasia. As Turkey approaches its centennial in 2023, the government has embarked on an ambitious journey to propel the nation to new heights, setting forth a series of formidable goals. These targets include achieving a colossal gross domestic product of $2 trillion, elevating per capita income to $25,000, increasing exports to $500 billion, expanding total import-export trade to $1 trillion, slashing unemployment rate to a mere 5%, enticing 50 million tourists, and striving to be ranked among the world's top 10 economies.

Tung Yu Hydraulic Group Celebrates 40th Anniversary

Tung Yu Hydraulic Machinery Co., Ltd., established in 1983, is a major hydraulic machinery manufacturer in Taiwan. We are dedicated to the research and development of high-quality hydraulic mechanical equipment and provide customers with a wide range of molding solutions. Tung Yu has successfully built a wide customer base in the international market, and our products are sold to more than 70 countries around the world.

Key Point of Lithium-Ion Battery: Coating Technique

The rapid growth of the lithium-ion battery industry is driven by increased usage of 3C products and electric vehicles. Lithium-ion batteries offer high energy density, environmental friendliness, and a booming market exceeding $50 billion by 2025. Coating techniques are vital for uniform electrode slurry application, with slot die technology providing advanced solutions.

JANDI’S: Cassava Bag Coopration with AVANI

Introducing cassava bags: eco-friendly, fully biodegradable, and compostable packaging made from renewable cassava starch. Exciting news: we've partnered with AVANI, a sustainability leader, to reduce plastic waste and promote responsible choices.

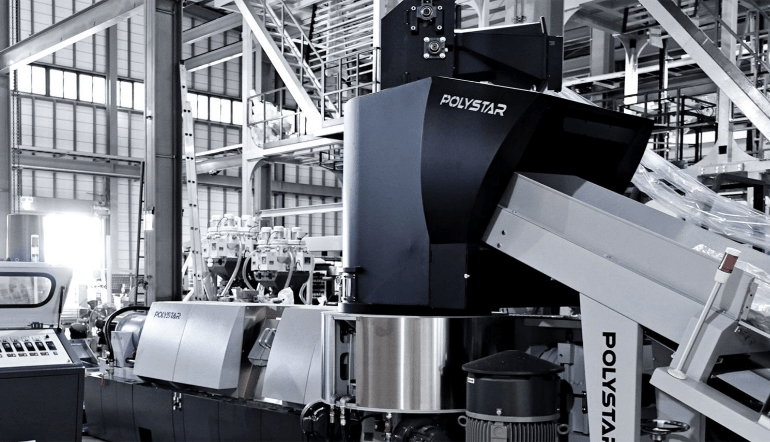

How to Boost Your Plastic Business Sustainability with POLYSTAR Recycling Machines?

Operating in the plastic industry requires consciousness of economic and environmental sustainability in favor of your business and the globe. Whether you are a professional recycler or plastic manufacturer investing in a stable plastic recycling machine can carry your business to a greener future. Read more to see which POLYSTAR recycling machine solution is the best fit for you.

JING-DAY: Customized Rubber Injection Machines for Highly Specialized Applications

Research, mold making, and production can be considered as critical processes in rubber molding technology. Jing-Day Machinery, originating from Taiwan, has accumulated over 40 years of knowledge and expertise in rubber and silicone molding since its establishment in 1983. This expertise allows them to excel in crucial technologies, enabling them to develop various specialized machinery and equipment for clients across a wide spectrum of industries.