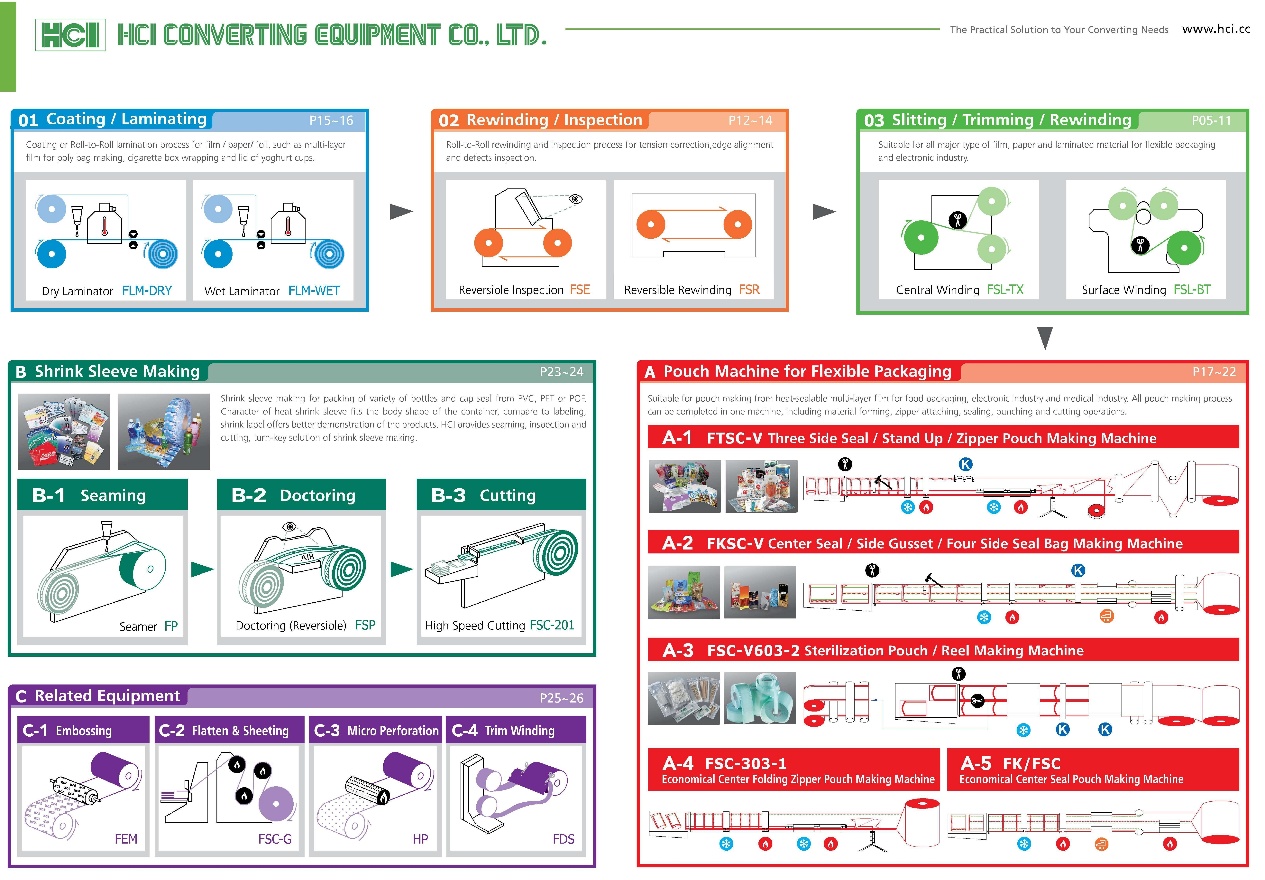

HCI: Optimizing Process and Creating Advantages

HCI, a solution provider of converting equipment in the flexible packaging supply chain, assisting customers in streamlining processes to convert products specification with upstream and downstream processing.

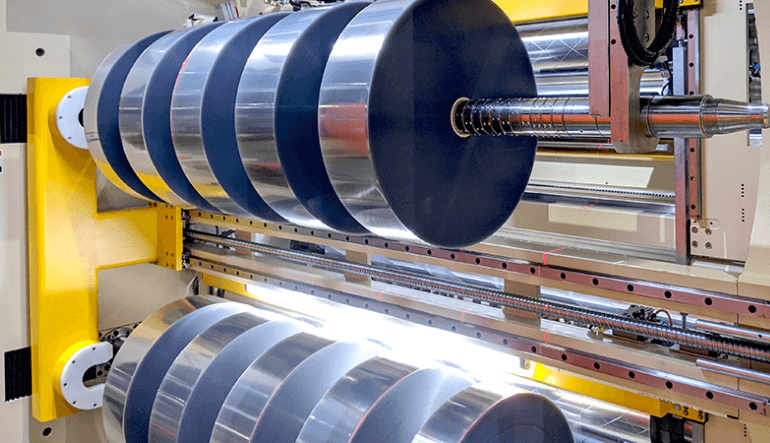

The latest FSL-TR1300 Turret Rewind Slitting Machine is designed for automatic slitting and rewinding operations, with automatic splicing and roll changing, stand-by paper cores auto positioning, finished rolls pusher and unloading device.

Turret Rewind Slitting Machine FSL-TR1300

And the FP-X250-2 Turret Rewind Seaming Machine for shrink sleeve making is equipped with rewind auto splicing, in-line lay flat and solvent auto detection capabilities, combining seaming and doctoring processes into one.

FP-X Turret Rewind Shrink Sleeve Seaming Machine

Those optimizations improve automation efficiency, reducing manual roll changing downtime, increasing efficiency, and enhancing production capacity. Also detecting and preventing defective products from entering subsequent processes, thus enhancing yield and reducing carbon emissions and waste generation. Through modular design and turnkey solutions, HCI supports customers in collecting process data and integrating it into a database to overcome bottlenecks and creating competitive advantages compared to their competitors.

HCI's core value is based on its 40 years of experience, which allows us to undertake customized equipment design and manufacturing. Acts as a "Box Cutter" for precise cutting (converting), assisting customers to overcome the bottle-neck encountered in its production and entering the blue ocean market competition together.

Within his work experience he has been involved in the strategic planning and launching in new products, also working close with customers for better understanding of their needs and also responsible of marketing strategies, branding and image of the company.