CORONA TREATER on H.L. RELEASE PAPER INDUSTRY

CUSTOMER

HL release paper industry has been in business for more than 35 years. It has had five production lines in Taiwan and Zhuhai Industrial Zone in Mainland China. With the concept of sustainable operation, it implements green product policies, sets up a toluene recovery device, and converts heavy oil to natural gas for improving resource usage. Products have passed SGS testing and certification.

PRODUCT

The major products are double-sided tape, foam tape, transfer tape and other types of adhesive tape backing paper, as well as a variety of self-adhesive trademarks, advertising version and special-purpose release paper. Process and formula are specially designed by each project process to meet the different requirement of peeling strength for various paper.

PROBLEM

European manufactured Corona technology was not reliable enough to meet the harsh working environment of daily commercial operation in Asia. Overpriced spare part and maintenance cost are also concerned.

PREVIOUS MANUFACTURING PRACTICES

H.L. release paper industry has not only low downed the power output of its European manufactured CORONA surface treater but also reduces the production speed to ensure that the quality of the final product can meet the requirements of its customers. This situation led to a drop in the production and efficiency.

SOLUTION

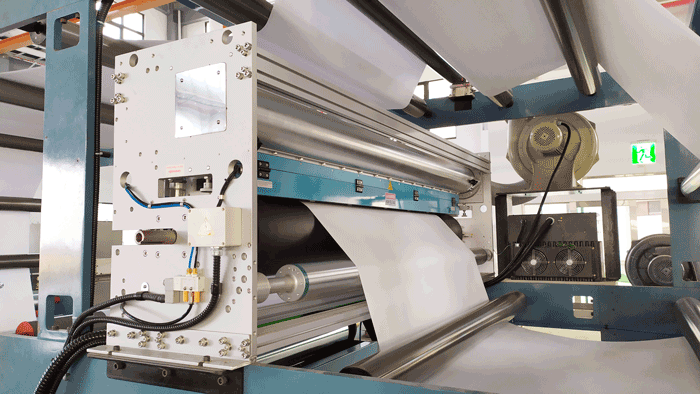

In January 2018, H.L. Release Paper Industry installed CHAANG HORNG - CORONA TREATER(MODEL: THH) into its coating lamination line as a replacement for the European manufactured CORONA surface treater.

The new CH’s CORONA surface treating system gave the company the ability to run at speeds 250 meter per minute with higher adhesion and product yield.

In December 2019, it installed a SECOND Chang Hong - Corona Treater (Model: THH ) as a replacement for another production line.

Chaang Horng - Corona Treater(Model: THH)

Author:CHAANG HORNG ELECTRONIC CO., LTD.

CHAANG HORNG ELECTRONIC is a leading manufacturer of CORONA & PLASMA systems used to increase the surface adhesion on plastic and metalized films.is dedicated to offering new and better solutions on surface adhesion treatment.

For 30 years, we’ve been the driving force behind technology innovation. We’ve engineered the most versatile series CORONA & PLASMA treating equipment to serve your needs and requirements.

With more than 12,000 installations in the field of film extrusion, printing and converting, we’ve globally offered solutions, solved problems, minimized down time and provided consistent adhesion and improved efficiency for customers.

Founded in 1988 and became a pioneer of corona technology. As a market and technology leader, we have used many customers’ experience to improve on designs utilizing corona and plasma technology and to obtain this technology’s success in the market.

Our CORONA & PLASMA treatment was constantly refined and increased to, always one step ahead of our customers’ demands.

For 30 years, we’ve been the driving force behind technology innovation. We’ve engineered the most versatile series CORONA & PLASMA treating equipment to serve your needs and requirements.

With more than 12,000 installations in the field of film extrusion, printing and converting, we’ve globally offered solutions, solved problems, minimized down time and provided consistent adhesion and improved efficiency for customers.

Founded in 1988 and became a pioneer of corona technology. As a market and technology leader, we have used many customers’ experience to improve on designs utilizing corona and plasma technology and to obtain this technology’s success in the market.

Our CORONA & PLASMA treatment was constantly refined and increased to, always one step ahead of our customers’ demands.