Polyamid 6 - NAH7200G20

Categories : PA(Polyamide) /Nylon

Glass fiber 20% reinforced, super high impact, black colored. Applications: Hand tools, Power tools, Gardening tools, Automobiles, motorbikes, bicycle parts and components, Spare parts of sports equipment, Electronics, Electrical cases and components, OA office components, Water supplies, Medical rehabilitation equipment.

Polyamid 6 - NA1200GK35

Categories : PA(Polyamide) /Nylon

Glass fiber 35% reinforced, high modulus, high impact. Applications: Hand tools, Power tools, Gardening tools, Automobiles, motorbikes, bicycle parts and components, Spare parts of sports equipment, Electronics, Electrical cases and components, OA office components, Water supplies, Medical rehabilitation equipment.

Polypropylene - PP1200G30

Categories : PP Resin

Glass fiber 30% reinforced. Application: Fan blades, Hand tools, Gardening tools, Sports equipment, Home appliances parts, Medical rehabilitation equipment, O.A. Office components.

Rubber Cutting Machine CRS

Categories : Rubber Cutting Machines

Nature rubber Rubber of metal bonded parts Oil-resistance rubber NBR+PVC concoction Synthetic rubber Medical/Pharmaceutical usage rubber Heat resistance rubber

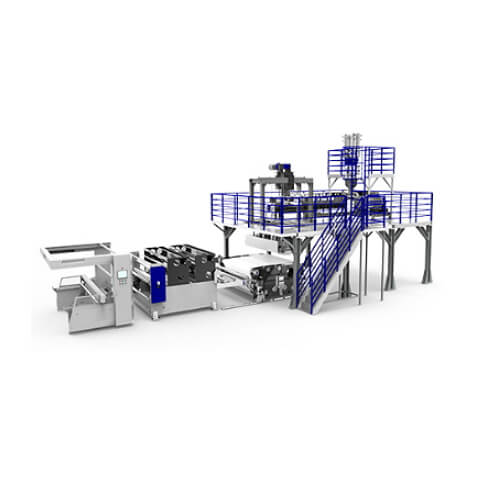

PP Meltblown Nonwoven Lines

Categories : Extrusion Lines For Filaments and Yarn

The JC-MB Series incorporates PLASCO signature innovation, quality, and efficiency to produce medical-grade nonwoven polypropylene fabric. This technologically-advanced fabric, possesing unique filtration properties, is one of the most in-demand textiles in the world. With the capacity to generate more than 1.5 tons of medical-grade fabric per day, the SCP-MB seris an invaluable addition to any business in the indurstry. Wheterh your business is expanding its current meltblown nonwonven polypropylene fabric entering the indurstyr, we are ready to develop your meltblown solution today!

Polyamid 6 - NAT1200

Categories : PA(Polyamide) /Nylon

High impact at low temperature. Applications: Hand tools, Power tools, Gardening tools, Automobiles, motorbikes, bicycle parts and components, Spare parts of sports equipment, Electronics, Electrical cases and components, OA office components, Water supplies, Medical rehabilitation equipment.

Polyamid 66 - NB1200G33

Categories : PA(Polyamide) /Nylon

Glass fiber 33% reinforced, high flow. Applications: Hand tools, Power tools, Gardening tools, Automobiles, motorbikes, bicycle parts and components, Spare parts of sports equipment, Electronics, Electrical cases and components, OA office components, Water supplies, Medical rehabilitation equipment.

Polyamid 6 - NA1100G45

Categories : PA(Polyamide) /Nylon

Glass fiber 45% reinforced, high flow. Applications: Hand tools, Power tools, Gardening tools, Automobiles, motorbikes, bicycle parts and components, Spare parts of sports equipment, Electronics, Electrical cases and components, OA office components, Water supplies, Medical rehabilitation equipment.

INSERT INJECTION MOLD

Categories : Injection Molds

INSERT MOLDING TECHNOLOGY: When a metal, plastic or ceramic part needs to be embedded in plastic to improve product structure it is called Insert Molding. It is a widely used process and one that YOMURA TECHNOLOGIES specializes in. With Insert Molding, a part is placed in a mold cavity then a selected plastic material is injected directly over it resulting is a single part with the insert(s) encapsulated by the material. This process normally uses engineering plastics for improved wear resistance, tensile strength and weight reduction. Insert Molding can be a highly efficient alternative to the assembly of discrete parts using soldering, connectors, fasteners, or adhesives. It also expands plastic capabilities and can reduce final product cost by limiting the amount of costly metal needed to create a part. And importantly, because we can use conventional single shot injection machines for Insert Molding, tooling costs are lower than with a multi-shot processing. Benefits: Reduced assembly and labor costs Because insert molding joins numerous components with thermoplastic, assembly and labor costs are greatly minimized. For example, a single stamping can be overmolded, then perforated to create multiple circuit paths. Reduced size and weight By eliminating fasteners and connectors, and by combining the physical strength of resin and metal inserts, insert molding yields smaller and lighter components. Increased reliability With every part tightly secured in thermoplastic, an insert molded component prevents part loosening, misalignment, improper terminations, and other problems. The thermoplastic resin also provides improved resistance to shock and vibration. Increased design flexibility Designers appreciate the virtually unlimited configurations that insert molding allows. For example, in creating a 3D circuit board, overmolding permits circuitry to move freely through the part, from inside to outside, up walls, down in holes-and the plastic ties it all together. Materials: Engineering plastic or Thermo Plastic Rubber (TPR) inserted with metal frame die casting, plated copper pin, sockets, wire frames, etc. Applications: TPR + Metal Frame(3C Mechanical Parts) ABS + Al. Die Cast (Sports/ Medical) Eng. Plastic + Patting Pin/Eng. Plastic + Wireframe (Connector) Eng. Plastic + Copper Pin/Contact (Precision Electronic Component)

Polyamid 6 - NA1100G33

Categories : PA(Polyamide) /Nylon

Glass fiber 33% reinforced, high flow. Applications: Hand tools, Power tools, Gardening tools, Automobiles, motorbikes, bicycle parts and components, Spare parts of sports equipment, Electronics, Electrical cases and components, OA office components, Water supplies, Medical rehabilitation equipment.

Polypropylene - PP1100G40H

Categories : PP Resin

Glass fiber 40% reinforced, high modulus. Application: Fan blades, Hand tools, Gardening tools, Sports equipment, Home appliances parts, Medical rehabilitation equipment, O.A. Office components.

CONTRACT ASSEMBLY

Our Electronic Manufacturing Service (EMS) is used to Co- design, test, manufacture, distribute and provide repair services for electronic components and assemblies for Original Equipment Manufacturers. We have provided Co- design engineering and contract EMS for the consumer electronics, industrial, medical, military and telecommunications markets. We specialize in a variety of contract assembly levels from high volume, complex electro-mechanical assembly & testing to small volume, conceptual prototype runs. For small to medium device assembly, we utilize a cost savings system of mobile workstations and conveyors that can be quickly grouped into private and secure assembly cells. MANUFACTURING CAPABILITIES Electromechanical Assembly Subassembly and/or Final Product Assembly RoHS Compliant Assembly Lean Manufacturing PLM, MES, QMS, System Dedicated Program Management Functional and Post-Assembly Test Verification Material Procurement and Consigned Management FACILITIES 10,000 & 100,000 class clean rooms Flexible cell production system Mass management with Manufacturing Execution System (MES) 30,000 sq ft floor space with room for expansion Large, medium or small minimum order quantity (MOQ) HR expertise to maintain qualified production workers 24/7 operations SUPPLY CHAIN MANAGEMENT SERVICES YOMURA TECHNOLOGIES has many years of material & component sourcing experience and has direct relationships with factories around the world. Our office has been designed to coordinate quick quotes, provide constant updates and track all data needed to communicate with and expedite all client orders. This ensures a smooth transition from placement of orders to delivery. We understand our clients need to keep inventory levels low to control costs, yet still need to respond quickly for new orders to satisfy your customer demand. Clients can leverage our supply chain management expertise to receive volume quality products without high inventory risk. By customizing our stocking and logistics programs to meet your production needs we can reduce your material inventory during all stages of development from prototypes all the way through high volume production orders. TEST ENGINEERING Our Test Engineering department is staffed with experienced engineers and technicians who excel at working with customers to develop methodologies and design fixtures to reduce overall manufacturing costs, improve production yields, identify failures early, support root cause analysis, and assist design engineering with test analysis. Yomura has more than15 years waterproof IP68 test. REWORK SERVICES Sometimes rework of existing product assemblies is necessary to fix a design flaw, upgrade an assembly with a new components, or simply to find a cost down solution. Our rework specialists assure that resulting assemblies will meet the highest quality standards. CERTIFICATIONS QUALITY SYSTEM AS9100 / ISO 9001 / ISO 14001 / ISO 13485 / TS 16949 / UL Compliant / FDA / MFi