Instant Recycling System

Categories : Plastic Waste Recycling Machines

In the past, operators throw away the sprues or waste material in small amount or wait for collecting them in big amount to reuse. However, that may be stuck dust by static electricity become too bade to be reused for a while. That not only occupies your space but also costs your time to assort, break plastic nature and regenerate in such long process. Yann Bang “Instant recycling system” use a crusher immediately granulate the sprues, waste material or NG product into small pieces as recycled material that be mixed with virgin material by a proportional valve in right proportion. The recycling process helps you cost down material outlay without effected quality. Small size with low noise and low power consumption is great for long hour operation. A small automatic peripheral instant recycling system for you molding machine combine with four individual equipments: crusher, automatic vacuum loader, hopper dryer and proportional valve. Also can be used with a robot or belt conveyor. The main function is to mix the granulated waste directly from the injection molding machine and the virgin material with a right proportion. Benefit you with less material ware and pollution for your standard productions. 1. Auto instant recycling system can recycle, convey and dry the granulated material sequentially. 2. Less noise and less dust to keep your working area clean. 3. Compact size, light weight and easy-to move. 4. Accurate mixing proportion for good quality. 5. Instant recycling provides the high-efficient productivity and save material cost.

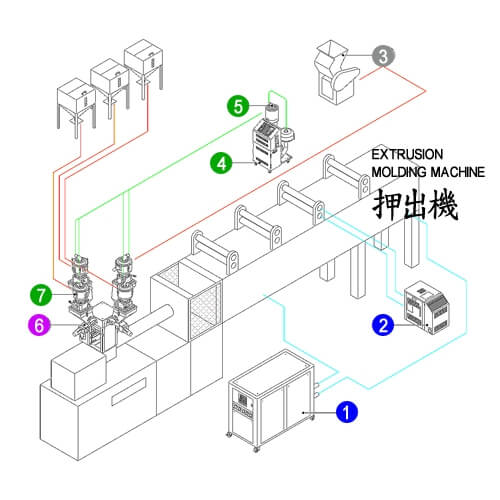

Extrusion Molding Machine Plastic Auxiliary Solutions

Categories : Assembly Systems

We are capable of offerring a wide range of auxiliary equipment specificaly for extrusion molding mechines, like hopper dryers, dehumidifying dryers, chillers, PET crystallizers, vacuum loaders, mold temperature controllers, master-bacth feeders and auto dosing and mixing systems. Better company image Greater productivity Lower cost Better energy efficiency Less material waste and pollution during the conveying process Better working environment Less noise due to the separation of the blowers from the working place