Control by computer automated process during the whole production

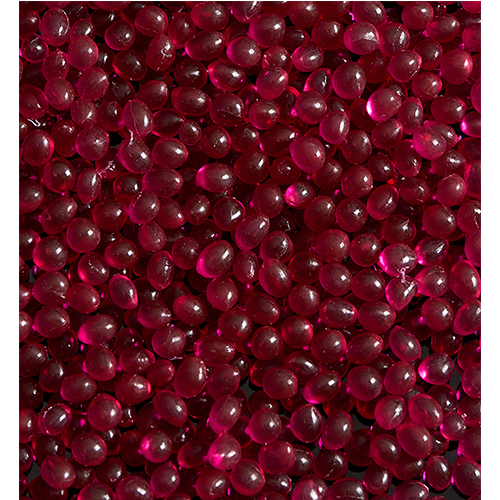

TPU resin, Thermoplastic polyurethane possesses the high toughness, mechanical strength, bio-compatibility, and resistance against oil, chemical, hydrolysis, and bacteria. It is perfectly suitable for injection, extrusion, blow film, and other sporting footwear application. ISOTHANE, TPU Resins Series are applied to EU chemicals policy (REACH regulation).

1. 1000 series Poly(adipate)ester based General Purpose Grade:

Suitable for Seals, Gaskets, Shoe Applications, Sporting Equipments and Mechanical Goods.

2. 1000E series Poly(adipate)ester based Elite Grade with High Transparency:

Suitable for Sheets, Film, Tube, Shoe Sole, and Shoe Upper.

3. 1000F series Poly(adipate)ester based FDA Grade:

Suitable for Sheets, Film, Tube, and Conveyor Belts.

4. 1100 series Poly(adipate)ester General Purpose Transparent Grade:

Suitable for Seals, Gaskets, Sheets, Tube, Cable, Shoe Sole, Sporting Equipments and Mechanical Goods.

● High Tensile Strength

● High Mechanical Property

● High Fuel & Oil Resistance

● Good Chemical Resistance

● Low Temperature Resistance

● Excellent Hydrolytic Stability

● Bio-compatibility

● Resistance To Micro-organism

ISOTHANE 1000 Series - General Purpose Grade

| Item Name | Poly(adipate)ester TPU resins General Purpose Grade |

|---|---|

| Characteristics | ISOTHANE 1000 series products are poly(adipate)ester based thermoplastic polyurethanes, thermoforming TPU. They exhibit excellent toughness, abrasive resistance, and solvent resistance. These products can be injection molded, blow molded, and extruded. |

| Suggested Applications | Seals, Gaskets, Sheets, Film, Tube, Cable, Shoe Sole, Sporting Equipment and Mechanical Goods. |

| Items | Units | ASTM | 1065A | 1070A | 1075A | 1080A | 1085A | 1090A |

|---|---|---|---|---|---|---|---|---|

| Specific Gravity | D-792 | 1.18 | 1.18 | 1.18 | 1.18 | 1.18 | 1.21 | |

| Hardness | Shore A | D-2240 | 65A | 70A | 75A | 80A | 85A | 90A |

| Tensile Strength |

MPa psi |

D-412 |

21 3500 |

21 3500 |

31 4500 |

34 5000 |

36 5300 |

55 8000 |

| @ 50% elongation |

MPa psi |

2 300 |

3 350 |

4 600 |

4 600 |

5 700 |

10 1500 |

|

| @ 100% elongation |

MPa psi |

3 500 |

7 950 |

5 700 |

6 900 |

7 1000 |

11 1600 |

|

| @ 300% elongation |

MPa psi |

5 800 |

7 950 |

9 1300 |

11 1600 |

14 2000 |

21 3000 |

|

| Elongation @ Break | % |

850 |

850 | 800 | 600 | 600 | 560 | |

| Tear Strength |

N/mm lb/in |

D-624 DIE C |

80 460 |

90 530 |

100 570 |

90 520 |

140 800 |

170 1000 |

| Items | Units | ASTM | B1095A | B1098A | 1055D | 1065D | 1160D | 1170D |

|---|---|---|---|---|---|---|---|---|

| Specific Gravity | D-792 | 1.22 | 1.22 | 1.21 | 1.21 | 1.21 | 1.23 | |

| Hardness | Shore A | D-2240 | 95A | 98A | 55D | 65D | 60D | 70D |

| Tensile Strength |

MPa psi |

D-412 |

60 8700 |

54 7800 |

43 6300 |

41 6000 |

40 5800 |

40 5800 |

| @ 50% elongation |

MPa psi |

13 1900 |

17 2400 |

15 2200 |

19 2700 |

15 2200 |

13 1900 |

|

| @ 100% elongation |

MPa psi |

15 2200 |

18 2600 |

19 2700 |

21 3000 |

19 2700 |

17 2500 |

|

| @ 300% elongation |

MPa psi |

25 3600 |

32 4700 |

33 4800 |

33 4800 |

33 4800 |

25 3700 |

|

| Elongation @ Break | % | 600 | 550 | 450 | 440 | 480 | 310 | |

| Tear Strength |

N/mm lb/in |

D-624 DIE C |

180 1100 |

220 1300 |

120 60 |

240 1400 |

200 1200 |

220 1200 |

ISOTHANE 1100 Series-General Purpose Transparent Grade

| Item Name | Poly(adipate)ester TPU Resins General Purpose Transparent Grade |

|---|---|

| Characteristics | ISOTHANE 1100series products are polyester poly(adipate)ester based thermoplastic polyurethanes. They exhibit good toughness, solvent resistance, easy processing, and high transparency. These products can be injection molded, and extruded. |

| Suggested Applications | Seals, Gaskets, Sheets, Tube, Cable, Shoe Sole, Sporting Equipments and Mechanical Goods. |