Classification : Industrial software products

Country: Taiwan

Phone: 886-3-5553111

Fax: 886-3-5555339

Contact Person: Yvonne

Products

Instant monitoring

|

Device Management

|

Molding Process Management

|

staff management

|

Production management

|

|

Product Advantages

Real-time monitoring capabilities can complete record machine production and personnel operating conditions. automated management workshop can be practiced. Recording not only machine operation state but also the production status and the non-productive status. makes managers understand the reasons why the machine is not in production, in order to develop appropriate management practices, enforce workshop management, and improve production efficiency and the effective use of the machine rate.

In addition to the normal product records, defect management functions allow users to choose the defective reason and number in the HMI defective screen when detect products are found, so that HMI will automatically send defective data to iNet. Through the defective management function, the operation of machines can be reviewed and corrected to increase the excellent product rate and production efficiency.

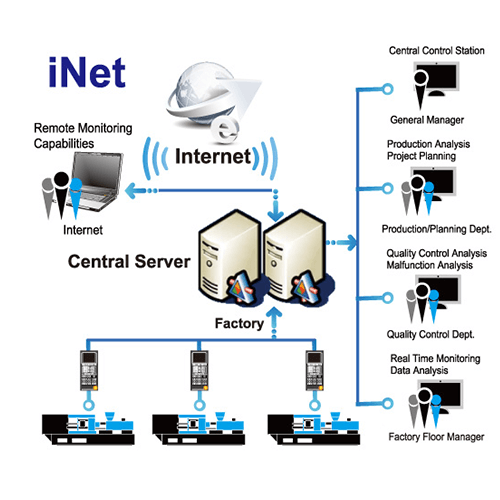

iNet is tailored specifically for managers as a "process management" tool, breaking the old management model and leading managers to enter the E management era.

Changes on the workshop management model allow managers to promptly and accurately understand the situation of on-site production and overall plan, to achieve networked production scheduling, device status, and automatically collect usage information. Standardized management of molding parameters greatly reduces production costs and improves productivity.

Product Features

1.Rapid and stable

|

2.Efficient management

|

3.Rich content

|

4.Unlimited freedom

|

5.Safe and reliable

|

6.Instant synchronization

|