Classification : Hydraulic Molding Machine

Country: Taiwan

Phone: 886-6-2320999

Fax: 886-6-2325333

Contact Person: Louis Tsai

- This series of machines is suitable for molding many different plastic related materials. Such as rubber, melon dishes, bakelite, urea powder, foaming, brakes, etc.

- PLC and HMI functional control as standard specification.

- Integrated hydraulic circuit provides various pipe functions on the circuit boards, reducing piping to a minimum. The oil cooler ensures long service life of the circuit valve.

- The motion time, and a number of other parameters can be conveniently set on the control panel to meet product variations, ensuring production quality.

- Combines two molding units in one machine, which can be operated separately.

- While in vulcanization molding operations, the hydraulic pump motor can be set for running, or stopped for power saving.

- The electric system is controlled by the PLC controller, allowing for easy operation and accurate adjustment. An emergency switch provides added safety for the mold and the operator.

| MODEL | JD-H50T | JD-H65T | JD-H80T | JD-H100T | JD-H150T | JD-H200T | JD-H300T | JD-H400T | JD-H700T | |

|---|---|---|---|---|---|---|---|---|---|---|

| Clamping Force | Ton | 50 | 65 | 80 | 100 | 150 | 200 | 300 | 400 | 700 |

| Plate Size | mm | 350 x 380 | 350 x 380 | 430 x 490 | 500 x 560 | 510 x 510 | 600 x 620 | 730 x 730 | 900 x 900 | 1200 x 1200 |

| Piston Diameter | mm | 180 | 200 | 230 | 270 | 310 | 355 | 430 | 500 | 660 |

| Piston Stroke | mm | 380 | 380 | 380 | 380 | 420 | 480 | 600 | 630 | 760 |

| Space Between Tie Bar | mm | 395 x 220 | 430 x 200 | 475 x 300 | 575 x 345 | 550 x 300 | 675 x 365 | 795 x 455 | 970 x 580 | 1360 x 800 |

| Oil Hydraulic System | HP | 5 | 5 | 5 | 7.5 | 7.5 | 7.5 | 10 | 10 | 25 |

| Platen Heating Capacity | kw | 4.8 | 4.8 | 9.6 | 12 | 12 | 13.5 | 20 | 30 | 43 |

| System Pressure | kg / cm² | 210 | 210 | 210 | 210 | 210 | 210 | 210 | 210 | 210 |

| Oil Tank Capacity | liters | 150 | 250 | 300 | 320 | 340 | 420 | 600 | 650 | 920 |

| Machine Dimensions | mm | 1300 x 700 x 1830 | 1300 x 900 x 2850 | 1680 x 980 x 1930 | 1770 x 980 x 2100 | 1800 x 1000 x 2000 | 2100 x 1200 x 2390 | 2200 x 140 x 280 | 2395 x 1590 x 2800 | 2800 x 2000 x 345 |

| Machine Weight (Approx) | kg | 2400 | 2600 | 2900 | 3600 | 3700 | 5100 | 7000 | 11500 | 14000 |

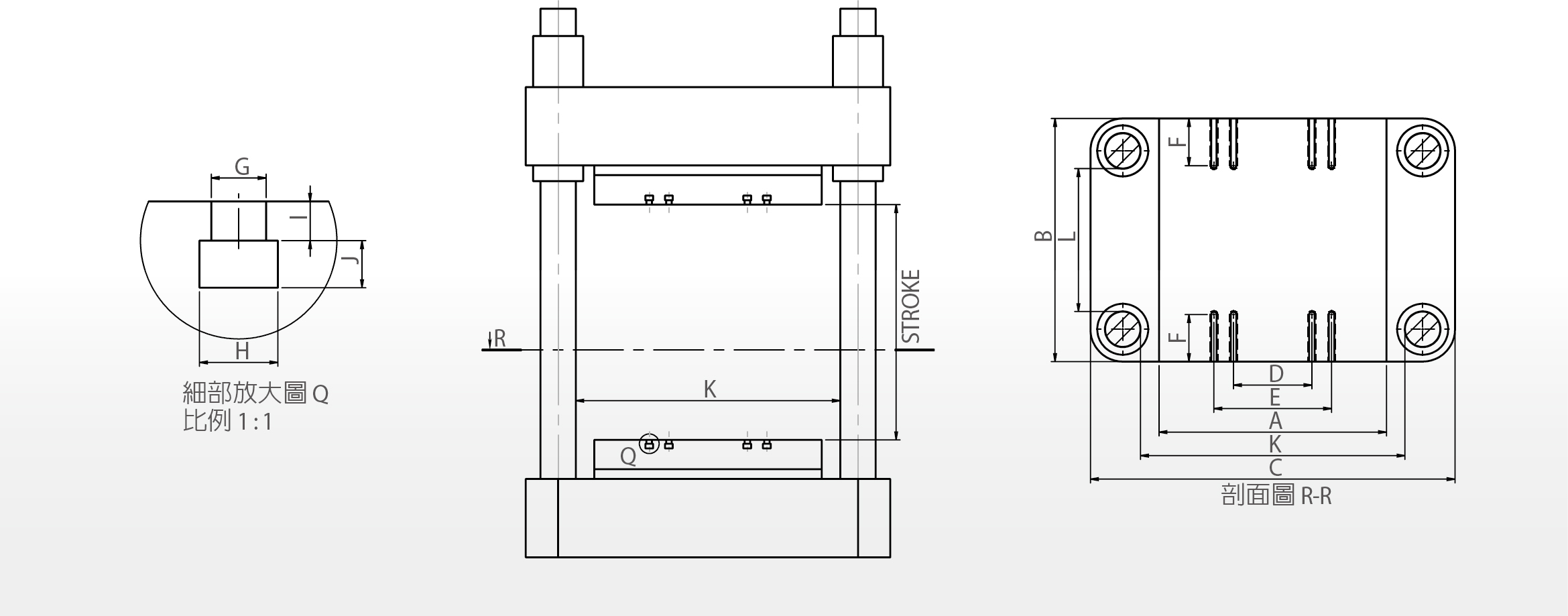

MOLD INSTALLATION & HEATING PLATE DIMENSION

| MODEL | JD-H50T | JD-H65T | JD-H80T | JD-H100T | JD-H150T | JD-H200T | JD-H300T | JD-H400T | JD-H700T | |

|---|---|---|---|---|---|---|---|---|---|---|

| STROKE | 380 | 380 | 380 | 380 | 420 | 480 | 600 | 630 | 760 | |

| DIMENSION | ||||||||||

| A | mm | 350 | 350 | 430 | 550 | 510 | 600 | 730 | 900 | 1200 |

| B | mm | 380 | 380 | 490 | 560 | 510 | 620 | 730 | 900 | 1200 |

| C | mm | 560 | 610 | 670 | 780 | 780 | 930 | 1060 | 1290 | 1760 |

| D | mm | - | - | - | 200 | 200 | 200 | 300 | 300 | 500 |

| E | mm | 200 | 200 | 200 | 300 | 300 | 400 | 500 | 700 | 1000 |

| F | mm | 135 | 135 | 135 | 135 | 135 | 200 | 200 | 250 | 350 |

| G | mm | 18 | 18 | 18 | 18 | 18 | 18 | 18 | 18 | 18 |

| H | mm | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| I | mm | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| J | mm | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 |

| K | mm | 395 | 430 | 475 | 575 | 550 | 675 | 795 | 970 | 1360 |

| L | mm | 220 | 200 | 300 | 345 | 300 | 365 | 455 | 580 | 800 |