PIRANHA-45, Mini recycling machine | Lung Meng

PIRANHA-45, Mini recycling machine | Lung Meng

5 Benefits of Flexo Printing Machines | PRM What to Say EP11

There are several types of printing techniques available for the plastic packaging industry. Such as flexo printing, offset printing, and screen printing. Although flexo printing is not a new technology, it is the most common method for packaging printing. Then let’s take a glimpse of the video to understand what flexo printing is and what makes it most preferable. Flexographic printing is a technique that uses a flexible printing plate. The plates are wrapped around cylinders on a web press. The inked plates have a raised image and rotate at high speeds to transfer the ink through small holes from the anilox roll to the substrate, which is the printed surface. So, what makes flexo printing the most common method? You will find 5 reasons why in the video.

2024 NPE Orlando Interview | ISI

I had the pleasure of meeting Mr. Joe Whann at NPE Orlando. Joe is not only brilliant but also incredibly friendly! He provided an insightful introduction to the wide range of services offered by ISI and shared how they have become a leading agent in the USA. Don't miss out on learning about their impressive journey and expertise!

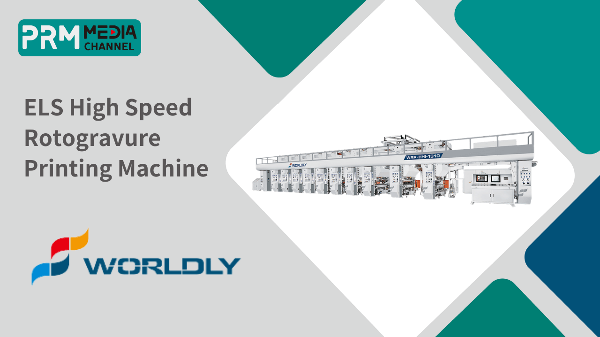

ELS High Speed Rotogravure Printing Machine | WORLDLY-

High-Speed ELS Rotogravure Printing Machine WRP-HHI-1300-10C series | WORLDLY Machine Specifications - Max machine speed: 350 m/min - Web width: 1000 / 1200 / 1300 mm - Printing cylinder circumference: 350 - 900 mm - Material diameter: 800 / 1000 mm - No. Color: 10 colors

Practical Solutions & Plastic Converting Equipment | HCI

【SPECIALTIES OF HCI】 Slitting Machines Rewinding / Inspection Machines Pouch Making Machines Medical Sterilization Pouch / Reel Making Machines Shrink Sleeve Seaming / Cutting / Doctoring Machines Embossing Machines 【ABOUT HCI】 Established in 1982, HCI Converting Equipment Co., Ltd. is a specialist in the design and manufacture of a full range of Roll-to-Roll and Roll-to-Sheet Converting Equipment and machinery for Flexible Packaging and Semi-Conductor, TFT-LCD, optoelectronics, Medical Industry (Sterilization Pouch/Reel Making Machine、Meltblown Fabric) and relative industries.

Ultrasonic Metal Welding Machine-ULTRA6200-M-WT | MING JILEE

ULTRA6200-M-WT Ultrasonic Metal Welding Machine

Bag on Roll Making Machine | COSMO

COSMO has many years of experience in bag making machines. We are still willing to have much more improvement and all the consumers are satisfied with the quality of machines offered to you. 【Machine Features】 2 lines coreless star sealed bag on roll making machine Oscillation film feeding & sealing system for stability and high out put Automatically reel changing system High production efficiency to save manpower and time Servo motor, as standard attachment, makes it easy to adjust the bag length and the production speed Computer control over the entire process From film roll to final bag, non-stop, one process flow Automatically stop when running out of film/ film feeding blocks or bags jam/ color scanning misses 【Company Introduction】 COSMO Machinery Co., Ltd. established in March 2001, is well-known for Taiwan manufacturing plastic bag making machinery with servo driving systems. The product from COSMO has the servo motor as standard attachment, makes it easy to adjust the bag length and the production speed, computer control over the entire process, component self-testing function available, high production efficiency to save manpower and time. Up to now, COSMO products are extensively exported to 100 countries spreading all over the world.

2024 CHINAPLAS Interview | Shubham Extrusion

We were delighted to have CHINAPLAS at the ETERLONG booth and meet their largest buyer in India for an interview with us. Mr. Nirav Shah shared that 15 years ago, TAIPEIPas found their trusted partner through PRM-TAIWAN

Quick Die Change | FORWELL

Quick Die Change - Quick Die Change System-qdcs-en-Forwell Features : • Decreased die change time • Designed for hydraulic and pneumatic presses • Increased efficiency • Reduced labor costs • Safer operations System Introduction : Forwell’s Quick Die Change System is an automatic die changing system that can be specifically designed for hydraulic and mechanical power presses and press production lines. This system automates the die changing process and provides increased speed, efficiency and productivity to a workshop. The Quick Die Change System not only reduces die change time, but also promotes diverse small batch production runs and streamlines production management. Quick Die Change Systems are becoming a standard for large manufacturers as they not only increase production efficiency, but also improve the overall working environment. The Automatic Die Change System can be built specifically for your machining requirements and will drastically reduce machine idle time during die changes, boosting your competitiveness. There are also a number of indirect benefits of installing a Quick Die Change System for your hydraulic and mechanical type press machines. Firstly, automated operations reduce labor expenses, but also reduce workshop accidents and the physical stresses on operators, making them more productive. Secondly, all dies can be changed without any modification allowing for the use of standardized die and press equipment, saving costs. Lastly, multiple presses can share a single Quick Die Change System, further economizing on costs and resulting in higher efficiency and productivity.

Best Choice Of PET Extrusion Pelletizing Machine Line From Partico Machinery, Inc | PARTICO

Model no:HF-FTO-135 3 in 1- Flow Channel Pelletizing System Double Filters system: no.1 Double pistons(Back flush) no.2 CPF Spec:The dia of screw 135mm Output:500-600kg/hr Application:PET yarn, flakes, fiber, filament

Slitting Machine SLIT-HSI 1600 | WEBCONTROL

Inspection Rewinding Machine-Inspection Machine-I1-Inspect J300-Webcontrol Webcontrol Machinery Corp has been specializing in manufacture of Inspection Rewinding Machine since 1988. Webcontrol ceaselessly develop new machine to extend production line for meeting various needs of customers. In additions, we constantly improve our Inspection Rewinding Machine with new technology, and innovate to enhances its performance, efficiency and reducing waste on production. Our consistently aim is to build high-performance, sophisticated Converting Machinery with inexpensive price as well as providing fast Inspection Rewinding Machine service ensure our worldwide customers must be satisfied.

Calcium Carbonate Compounding Pelletizing Plant | GENIUS

Calcium Carbonate Compounding Pelletizing Plant-Genius Specializes in CALCIUM CARBONATE (CACO3) COMPOUNDING Pelletizing Plant, GENIUS MACHINERY CO., LTD. was established in 1992, professional in CALCIUM CARBONATE (CACO3) COMPOUNDING Pelletizing Plant production line equipment design and planning. It also has the best credential and experience in shredder machine, waste cleaning line, film recycling machine. We are not only selling our CALCIUM CARBONATE (CACO3) COMPOUNDING Pelletizing Plant products in Taiwan, but also we export our product to China, Indonesia, Philippines, and Saudi-Arabia, in order to promote the excellent technology, reputation and quality which are exclusive features of Taiwan to the whole world. Product Feature Applicable materials For PP、LDPE、PS. For adding in plastic product production; maximum caco3 up to 80%~90%. • Save cost, reduce expenditure, strengthen competition. • Pellet is round and flat in shape, smooth feeling, well plastified, good dispersibility. • Easy operation

2023 VietnamPlas Interview | Chan Chao

It's our great honor to interview Tracy from Chan Chao. Tracy also introduced their services in holding worldwide exhibitions.

Live stream on 2022 Taichung Industrial Automation Exhibition

This year we are attending Taichung Industrial Automation Exhibition and we are excited to share with you by hosting a Live stream. Let PRM show you an online tour of the exhibition and you will have a quick look and receive industrial news, and the latest machines and equipment. Date & Time: July 16th, 2022 15:00 (GMT+8) Location: Taichung International Exhibition Center (TCIEC), Taiwan The exhibition includes: Plastic packaging manufacturing machinery Hardware & Accessory Equipment Area Cutting Tools Area Machine Tools Area Industrial Machinery Area Warehousing & Handling Equipment Area Inspecting Measuring & Testing Equipment Area Surface Finishing Are

CHINAPLAS On-site Tour Hall No.1-6 | PRM-TAIWAN

Hello everyone! It's been a long time since last CHINAPLAS Let one of partner from PRM—— Joey Show you all the fantastic things at CHINAPLAS Welcome to PRM's booth if you are interested in the first-hand marketing and trade news of the Plastic and Rubber industry.

Paper Bubble Mailer Making Machine, MGA 47P 1000 | MING JILEE

Paper Bubble Mailer Making Machine, MGA-47P-1000 Learn More:https://www.mingjilee.com/tw/product/... MING JILEE: PP Extrusion Line and Bag Converting Machine Since 1987 Made In Taiwan, Best Quality and Global Support Website: https://www.mingjilee.com/ E-mail: [email protected] Whatsapp: +886 934 081 955 Complete Address: No.76-8, Ming-Ho, Ming-Ho Vil., Shan-Shang Dist., Tainan City, 74342, Taiwan

How 2025 U.S. Tariffs Will Reshape the Plastics Industry | PRM What To Say EP20

In this episode of PRM What To Say (EP20), we dive into the latest developments of the 2025 U.S. tariff policy and its profound impact on the plastics industry. What do the new 245% tariffs on China mean for global supply chains? How will Taiwan, Japan, Korea, and Europe be affected? Join us as we analyze the key changes, challenges, and future opportunities for plastics manufacturers worldwide. Topics Covered: U.S. reciprocal tariffs overview Strategic moves for manufacturers in 2025 Don't forget to subscribe for more insights on global trade, plastics machinery, and industry trends!

2024 CHINAPLAS Interview | ARBURG

I'm honor to meet Dr. Christoph Schumacher, the vice president Global Marketing from Arburg. Let's hear about what's his thoughts on Chinaplas! And their new type machine launched in China.

Core Objects for Plastic & Rubber Machines | NAN YUN

Do you know SCREWS and BARRELS? Those are dispensable parts to injection molding machines, extruders and relevant machines in the plastic and rubber industry. Nan Yun Industrial Co., LTD., an expert who specializes in designing and manufacturing a full range of screws and barrels. With more than 30 years of experience, Nan Yun’s team provides customization services to meet customer’s special applications. By interviewing Mr. Kuo-Feng Huang, Assistant Manager of ST Dept., we also discussed an important engineering technology concept “Reverse Engineering” and how Nan Yun applied it into their business. Moreover, after-sales service is one of Nan Yun’s values. By Gathering feedback and reviewing consultation forms in past years, they could provide accurate solutions to their customers. 【Video Outline】 00:00 - Introduction 00:45 - The role of Nan Yun 01:22 - The specialty of Nan Yun 03:03 - Service during the pandemic 03:37 - Solutions to customer’s problems 04:25 - Future plans and messages to customers 05:23 - Closing

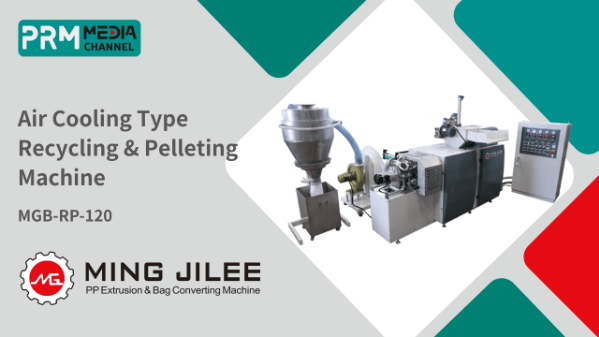

Air Cooling LD/HDPE Recycling Machine, MGB-RP-120 - MING JILEE

Air Cooling LD/HDPE Recycling machine is designs for re-pelletizing PE plastic waste material / t shirt bag die cut wasteThe material can be PE blown film waste, T shirt bag handle die cut waste, etc... Air Cooling Type Plastic Recycling Machine is equipped the power save, the SCR power regulator control. The real power consumption is around 15~20 kg. 1. Machine Specification: (1) Machine dimension a. Main machine : 2,770 (L) × 2,530 (W) × 2,060 (H) mm b. control box : 920 (L) × 420 (W) × 1,660 (H) mm (2) Machine weight : 2,430 kg (3) Power preparation : 45 kg (4) Power consumption : 20 kw 2. Machine Performance: (1) Applicable resin : LDPE / LLDPE / HDPE Waste Film (2) Output a. LD/LLD PE : 50 - 60 kg/hr b. HD/ PE : 40 - 50 kg/hr Air Cooling LD/HDPE Recycling Machine Features: (1) SCR power regular for saving power (2) Rotating die cutting head to get good quality of cutting shape (3) Less space required (4) Extra Cooling fan to cool down the PE material. Air Cooling Type Plastic Recycling Machine Further information: https://www.mingjilee.com/en/product/...

Water Transfer Printing Dipping Machine | YHT

Since 1990, YHT has been a manufacturer for Printing High Definition Water Transfer Films, leading the way with short new pattern development time, quick lead time to turn around on film printing orders, and providing many solutions to qualify customers demands. We have been supplying films to many famous brand companies all around the world, and these work experiences have made us irreplaceable on Water Transfer Printing (WTP) business. We not only do printing films, but we also make relevant dipping and wash machines to supply a completed chain of product. 【Advantages of our Water Transfer Printing】 Color and design of the pattern through water pressure Decoration is possible for many sizes, shapes, and flexible products 【Applied Products】 Ski goggles, EVA shoes, electric switches, rifle scope, firearm, crossbows, dog leashes, home appliances, car panels, and steering wheels are all in the scope of WTP process.

Business Tips of Choosing Plastic Recycling Machine | PRM What To Say EP17

Do you understand different kind of plastic recycling machines? Each type of plastic could be processed by certain type of machine. If you are still confused in choosing machines for your business, you must watch this video.

High Speed Zipper Bag Making Machine With In-Line Zipper Lamination | MGA-06Z-800D

High Speed Zipper Strip Hot Lamination Side Sealing Machine, MGA-06Z-800D Zipper bag side sealing machine is latest design to produce zipper bag / Ziploc bag / IKEA zipper bag/ grape bag/ slider zipper bag. The zipper bag side sealing machine is equipped 3 sets of servo motors to control the best tension and high speed production. The zipper bag side sealing machine is equipped in-line zipper strip sealing station. MACHINE PERFORMANCE (1) Feed material : LDPE, HDPE, PP, EVA (2) Single layer film thickness a. Side sealing bag : 0.02 - 0.08 mm b. zipper bag : 0.04 - 0.08 mm (3) Effective bag width (feeding length) : 85 - 600 mm (4) Effective bag length (sealing width) : 150 - 650 mm (5) Output : 40 - 200 pcs /min (depend on size and thickness) FEATURES (1) The PLC controller is made in Taiwan and very stable. (2) The size control of Zipper Bag Side Sealing Machine is by servo motor. Made in Japan (3) Zipper Bag Side Sealing Machine is equipped mark sensor for printed material (4) For getting the best quality of zipper bag product, unwinding station is mount the auto tension control (5) The individual zipper strip unwinder with motor control to get the high quality of zipper sealing quality. (6) Ultrasonic welding is design by motor driven for highest speed production (7) The ultrasonic welding station to crack the zipper on the edge of the bag for easy side sealing cutting. (8) the best design of zipper bag side sealing machine, made in Taiwan