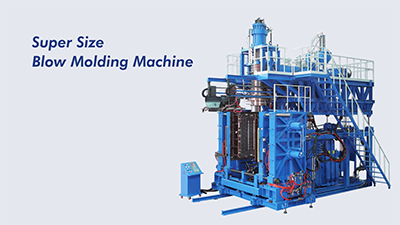

Blow Molding Machine | CHEN WAY

CHEN WAY machinery is a specialized manufacturer in Taiwan that keeps focusing on the customized R & D for blow molding machines since 1990. Our blow molding machine produces mainly hollow plastic vessels ranging from 20ML to 2000L. Every machine is tested rigorously according to the customer production requirement, this process ensures that every machine can run with its maximum effectiveness. [Products List] + Small Blow Molding Machine + Medium Blow Molding Machine + Medium Co-extrusion Blow Molding Machine + Large Blow Molding Machine + Supersize Blow Molding Machine + Double L-Ring Drum Blow Molding Machine + Semi-auto Stretching Blow Molding Machine

5G PET Preform Turnkey | KING'S SOLUTION

5G PET Preform Turnkey - 5 Gallon PET Preform Injection Molding Machines & Whole Plant Turn-Key Solution-pet-King's Machinery. FEATURES Select from 2, 4 or 8 cavities mold specifications. Single mold, 4 cavities design. The 2 stage material feed system raises the repeatability rate, lowers the cycle time, and boosts performance. When combined with a secondary cooling system, performance can be doubled. Temperature control via TSR raises temperature accuracy and, working with the accumulator, increases injection speed. Unique economical design is twice as energy efficient as comparable commercial units. we offer a complete set of 5 gallon PET bottle manufacturing equipment: raw material dehumidification and drying system; fixed-volume color additive; quickly stabilizing PET bottle preform molding machine; 4 cavity, hot runner mold; rapid cooling robot; and bottle blowing machine. From raw material to finished product stages, this all-inclusive system promotes high productivity, low cost, and superior quality-the bottle blowing defect rate is kept to a minuscule 0.5%. When water is shortage and lack of quality sanitary sewer, therefore, water container or bottle is convenience to filling in clean water and to carry with to the public. Moreover, bottle is not only for water-use but also oil-use even other liquid-use. King's gallon-size pre-form is one of the best choices in worldwide. Not only does save 20% of shipping cost but also decrease defect of blowing rate down to less 0.5%. And the most critical point is that any color is so clear by King's latest technology and 20 years PET knowledge.

Single-stage Injection Stretch Blow Molding Machine | GOLFANG-

Golfang treasures what have been entrusted... customizing special machine with molds for each customer. Golfang specializes in the development and manufacture of " single-stage injection stretch blow molding machine". Provide customers with a whole set of production equipment which includes customized machine and mold. Strictly control the quality and reliability of all assembly parts. Do the test runs repeatedly including mold testing and material testing before delivery. Obtain the most stable molding parameters based on the molding characteristics of the plastic specified by the customer and the adjustment during the bottle production. Meet the customer’s quality and production capacity requirements. Finally, after the machine acceptance, transfer the molding technique to the equipment user and do the personnel training. The equipment ca be run in full-time production with durability, high-efficiency, and high-stability, which creates the best return on investment for the customer. It is also the first choice for producing high-end plastic packaging containers when small quantities, varieties, and high quality are required at an early development stage. The Golfang team has accumulated many years of experience in the field of plastic product: PPSU baby bottles, PC/PMMA lampshades (LED light bulbs), HIPS yogurt bottles, PP/PE/PET medicine bottles, TRITAN water bottles, PET/PETG cosmetic bottles, household product bottles, etc... exquisite packaging containers. Also cooperated with the customers in developing products for well-known brands, include Pigeon, AVENT, Nuby, Yakult, Unilever, LOREAL, AVON, SHISEIDO, Pfizer, etc. Mold development is nothing more than a solution to product market demand. In the field of injection blow molding, Golfang insists on research, design, and manufacture of exclusive molds, and never relies on others, because we know that molds are designed and developed in response to the equipment. When customers evaluate and launch new product according to the market trend, what they need is stable quality and the chance to get ahead of the game. Therefore, with Golfang’s established and mature molding technique, whether it is the mold’s durability (2 million cycles guaranteed) or the delivery time, Golfang is always the most reliable choice for the customer. The common design of mold bases and mold parts is able to save mold costs and improve competitiveness for the customers. It provides them with the most economical solution. Golfang would communicate on product sizes beforehand and suggest for minor alteration. In such a way, Golfang gains good recognition from the customers.

Plastic Injection Molding Innovations and Green Solutions | KING'S SOLUTION

Livestream time: November 20th at 19: 00 (GMT +8, Taipei) The Livestream that PRM Media Channel held with KING'S SOLUTION CORP. with the title of Plastic Injection Molding Innovations and Green Solutions brings you new insight into the injection molding machine industry. Remember to direct your questions in the live chat section, KING'S SOLUTION and PRM Media Channel will be replying to your questions. What are the challenges, trends, and innovations in the injection molding industry? How to sustain after-sales services during post-pandemic? What advantages LPM (Low-Pressure Molding) brings to the manufacturers compared to Epoxy Injection Molding? Do you also have similar questions like that or would like to learn more? Then we welcome you to watch the Livestream video on November 20th at 19: 00 (GMT +8, Taipei) 【VIDEO OUTLINE】 00:00 Opening 00:59 KING'S SOLUTION CORPORATION 02:00 "Green Solution, Machine Soulmate" Slogan 03:04 Why to customize the machines? 05:00 Customized Machine Series 06:00 Market Challenges and Successful Cases 10:38 5 Gallon PET Preform Injection Molding Solutions 12:35 Advantages of KING’S in 5 Gallon PET Preforms 16:16 Trends in Injection Molding Market 18:40 LPM Application Examples 23:00 LPM Method vs Epoxy Method 26:00 After Sales Services and Customer Relations 28:55 Message to Current and Potential Customers Know PRM Media Channel more on: PRM Media Channel Website: https://bit.ly/3uqdubs PRM Facebook: https://www.facebook.com/PRMMediaChannel PRM LinkedIn: https://www.linkedin.com/company/prm-taiwan/

Waste Material Recycling Equipment at K 2022 | GENOX

It was a great honor for PRM-Taiwan to invite Jamie Jiang — the Marketing Director from GENOX. In the interview, we talked about the macro economic market during the pandemic, and the forecast for the future. In the end, Jamie also mentioned that the K Show is a worldwide exhibition for partners from the Plastic & Rubber industry, people can gain the newest industry information at the show.

Liquid, Solid and Granule Food Packaging Machine Solutions | SAN TUNG Interview

At the last version of the TAIPEI PACK exhibition, PRM Media Channel had an interview with SAN TUNG MACHINERY. We invite you to take a look at the food packaging machine solutions and industry observation of SAN TUNG. In the video, you will find the on-site machine introduction of - Liquid Food Packaging Machine Solutions - Solid Food Packaging Machine Solutions - Granule Food Packaging Machine Solutions by the demonstration of Mr. Yao & Ms. Cathy. Moreover, Ms. Cathy is also sharing her insights into the current situations in the packaging industry, and her expectations of future cooperation with their clients.

Fibrillated Tape Extrusion Line (JC-FYB) | PLASCO

PLASCO's JC-FYB Series of extrusion lines are designed to produce either standard or heavy-duty fibrillated tape for technical end-use applications, such as baler twine, insulated cable filler, carpet backing, synthetic grass, and more! 【Machine Spec】 Applicable Materials: PP / HDPE Screw Diameter (mm): 85 / 100 / 110 Denier (D): 3000-25000 / 3000-30000 / 3000-35000 Working Width (mm): 800 / 1000 / 1200 Extrusion Capacity (kg/hr): 120 / 200 /250 【Application】 Rope Cable filler Baler twine 【Company Intro】 PLASCO is a global industry leader in the design, manufacture, and supply of innovative plastic extrusion lines. They specialize in applying innovative engineering concepts to the design and manufacture of plastic extrusion lines with more than 30 year experiences.

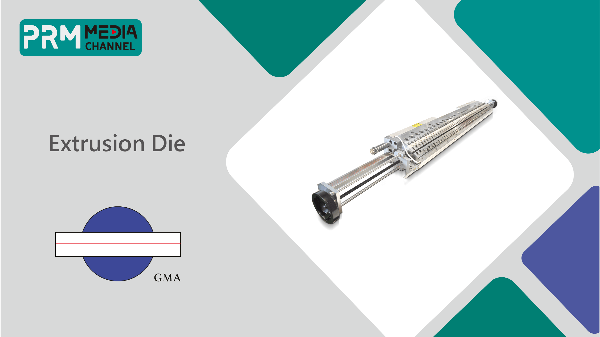

Extrusion die and peripherals manufacturer | GMA

Founded in 1989, the GMA Machinery Enterprise Co., Ltd. (GMA), an R&D team composed of senior design engineers and technicians with decade’s strong experience in sheet and film extrusion equipment and auxiliary parts, has been devoted to providing custom products based on customer requirements. With 30 years of continuous efforts, it is the one of the best manufacturer in the world. Based on comprehensive processing equipment, GMA is able to exercise strict quality control throughout the whole in-house process from product design, manufacturing, assembling and inspection which, in turn, has earned customers’ continuous recognition and praise.

Automatic Rotary Sealing machine(Bowl/Cup) Manufacturer | ET-80L3D8 | YF-SUPER SEALER | Y-FANG

Y-Fang Automatic Rotary Sealing Machine (ET-80) is designed to provide seamless and efficient sealing for bowls and cups. This advanced machine offers a fully automated process, from product loading to precise sealing, ensuring a secure and airtight finish every time. Its compact design is ideal for businesses seeking to maximize efficiency while maintaining high standards of hygiene and product quality. With easy operation and robust construction, the ET-80 is the perfect solution for streamlined packaging in the food and beverage industry. Application ✔️Suitable for beverages, Pudding, Jelly, Fast-food, Snacks, Various prepared foods for the microwave, Seasoned frozen food, Pickled foods, Seafood, processed agricultural products, etc. Which load into the cup and tray. ✔️Sealable material: PP, PE, PS, PET, HDPE, EPS, PSP, Aluminum foil, Paper box, etc. ✔️For smaller working spaces but higher capacity. Y-fang Group was established in 1985, specialize in the design and manufacture of sealing machines for various industrial applications. With over years of manufacturing experience, we are able to produce a wide range of tray sealing machines with a capacity of 450 to 600 pieces per hour. Our machines can perform a variety of different functions such as auto-dropping, piston filling, date printing, vacuuming, and gas flushing (MAP: Modified Atmosphere Packaging). Furthermore, we are also able to provide our customers with OEM, ODM, and OBM manufacturing solutions. Our products have been exported to countries over the world, including Europe, Asia, Africa, and America.

Thermoforming Machine | CHULIING

Thermoforming Machine-Continuous Thermoforming Machine Chuliing Machinery Co., Ltd was established in 1985 and is now an expert in manufacturing Thermoforming Machine. Our products are sold worldwide and we are well-known die cutting machine manufacturer. Chuliing Machinery has a commitment to technological innovation so as to benefit his customers and agents from all aspects. We also dedicate ourselves to develop automatic equipment and to train our employees to further enhance our Thermoforming Machine product quality.

TungYu Energy Efficiency Servo Press(CE) | Tung Yu

⚫Servo motor drive:Servo press use servo motor as the power source, with transmission mechanism and pressure sensing element to provide the required power for the press, and link the guide screw straight joint press head (or center base) to directly provide the required load for the workpiece. ⚫Planetary roller screw:Planetary screw uses a roller instead of a ball between the screw and the nut to greatly improve the rigidity and increase the contact area. The roller rotates around the screw in the same way as the earth orbits the sun, and the loading capacity is three times that of a ball screw, which improves stability and thus extends the life of the screw. ⚫Independent heating platen temperature control system:Provide preheating function before the mold waiting for hot press molding, shorten the hot press molding time and improve the production efficiency. ⚫Energy saving and environment cleaning:The power consumption rate of the servo motor is more economical than traditional motor with pump design.Without hydraulic system there is no oil leakage and low maintenance.It is suitable for working environments with low pollutions, such as electronics industry, biotechnology industry, etc. ⚫Precise movement:Control parameters can be input from HMI, and action commands can be issued to driver through PLC and implement servo motor actuation to achieve high-precision control on working force, speed or position performance. The servo motor is directly connected to the lead screw head (or moveable traverse) through the transmission to have direct required load.The features are to precisely provide key parameters of working force, speed and position in production. ⚫Complete process setting function:It is convenient for the user to set up process parameters and save portable files as backup. ⚫Convenient data tracking and statistical result output:The data and graphs of each cycle could be presented as batch statistical information for tracking by operator easily. ⚫Real-time monitoring of press status:Display of cycle graph and monitoring of press status, sensors and statistics. Real-time production information such as quantity and yield rate to improve the control efficiency and accuracy.

Plastic Bag Making Machine | WorldSteel

Suitable for a range of shapes folds and pockets, interlinking with other equipment to be able to make even more types of bags for easy exchange. Pattern types include: punching equipment for round holes, butterfly holes, utilizes handheld punching equipment for accuracy and can produce perforations for letter and packaging tear off strips. Using a vertical up and down heat sealing system and supersonic sealing line device. Provide extra parts for improved production accuracy and quality, including EPC edge sensor, servo motor to drive the machinery and an automatic conveyor to get your finished products to the packing section as soon as possible. Suitable for already perforated and/or folded films. 【Company Introduction】 World Steel Machinery Company is dedicated to making technological innovations and manufacturing packaging machines.They have the best engineering crew in the industry to provide total solutions which include design, customization and development. If you are looking for machines that produce, flower sleeves, diaper bags, book sleeves, self adhesive bags, handle bags, sandwich bags or more, then World Steel is the best choice for you.