Bag Making Machines for Multiple Applications | WORLD STEEL

World Steel Machinery Company is located in Taichung City, Taiwan. With over 35 years of experience, World Steel is dedicated to making technological innovations and manufacturing packaging machines. The company has one of the best engineering crews in the industry to provide total solutions which include design, customization, and development. If you are looking for machines that produce, flower sleeves, diaper bags, book sleeves, self-adhesive bags, handle bags, sandwich bags, or more, then World Steel is one of the best choices for you.

Full Electric PK-95CD-E (PE) (Toggle) Single Station Double Heads Blow Molding Machine | PARKER

PARKER PK-95CD-E (PE) (Toggle) Single Station Double Heads Blow Molding Machine

Fibrillated Tape Extrusion Line (JC-FYB) | PLASCO

PLASCO's JC-FYB Series of extrusion lines are designed to produce either standard or heavy-duty fibrillated tape for technical end-use applications, such as baler twine, insulated cable filler, carpet backing, synthetic grass, and more! 【Machine Spec】 Applicable Materials: PP / HDPE Screw Diameter (mm): 85 / 100 / 110 Denier (D): 3000-25000 / 3000-30000 / 3000-35000 Working Width (mm): 800 / 1000 / 1200 Extrusion Capacity (kg/hr): 120 / 200 /250 【Application】 Rope Cable filler Baler twine 【Company Intro】 PLASCO is a global industry leader in the design, manufacture, and supply of innovative plastic extrusion lines. They specialize in applying innovative engineering concepts to the design and manufacture of plastic extrusion lines with more than 30 year experiences.

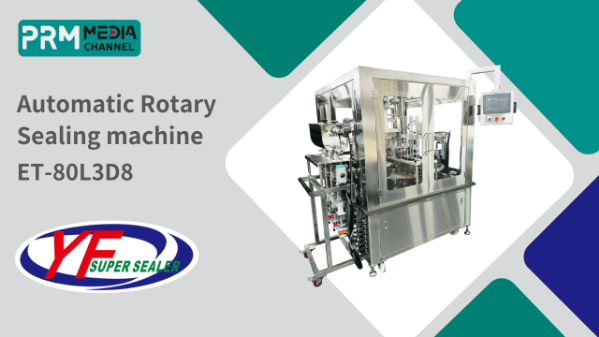

Automatic Rotary Sealing machine(Bowl/Cup) Manufacturer | ET-80L3D8 | YF-SUPER SEALER | Y-FANG

Y-Fang Automatic Rotary Sealing Machine (ET-80) is designed to provide seamless and efficient sealing for bowls and cups. This advanced machine offers a fully automated process, from product loading to precise sealing, ensuring a secure and airtight finish every time. Its compact design is ideal for businesses seeking to maximize efficiency while maintaining high standards of hygiene and product quality. With easy operation and robust construction, the ET-80 is the perfect solution for streamlined packaging in the food and beverage industry. Application ✔️Suitable for beverages, Pudding, Jelly, Fast-food, Snacks, Various prepared foods for the microwave, Seasoned frozen food, Pickled foods, Seafood, processed agricultural products, etc. Which load into the cup and tray. ✔️Sealable material: PP, PE, PS, PET, HDPE, EPS, PSP, Aluminum foil, Paper box, etc. ✔️For smaller working spaces but higher capacity. Y-fang Group was established in 1985, specialize in the design and manufacture of sealing machines for various industrial applications. With over years of manufacturing experience, we are able to produce a wide range of tray sealing machines with a capacity of 450 to 600 pieces per hour. Our machines can perform a variety of different functions such as auto-dropping, piston filling, date printing, vacuuming, and gas flushing (MAP: Modified Atmosphere Packaging). Furthermore, we are also able to provide our customers with OEM, ODM, and OBM manufacturing solutions. Our products have been exported to countries over the world, including Europe, Asia, Africa, and America.

Plastic Bag Making Machine | WorldSteel

Suitable for a range of shapes folds and pockets, interlinking with other equipment to be able to make even more types of bags for easy exchange. Pattern types include: punching equipment for round holes, butterfly holes, utilizes handheld punching equipment for accuracy and can produce perforations for letter and packaging tear off strips. Using a vertical up and down heat sealing system and supersonic sealing line device. Provide extra parts for improved production accuracy and quality, including EPC edge sensor, servo motor to drive the machinery and an automatic conveyor to get your finished products to the packing section as soon as possible. Suitable for already perforated and/or folded films. 【Company Introduction】 World Steel Machinery Company is dedicated to making technological innovations and manufacturing packaging machines.They have the best engineering crew in the industry to provide total solutions which include design, customization and development. If you are looking for machines that produce, flower sleeves, diaper bags, book sleeves, self adhesive bags, handle bags, sandwich bags or more, then World Steel is the best choice for you.

Double Injection Mold Expert & Solution | YOMURA

Yomura Technologies Inc. was founded in 1989. With over 30 years of experience, we have been selected as OEM by multiple world-class brands. Moreover, Yomura has the tooling expertise to fabricate complex, high-end molds and the production capacity to manufacture large volumes of precision parts for just about any industry, such as 3C consumer goods, medical, automotive, aerospace products, military & industrial gear and more. 【Service Line】 Single Injection Mold Double Injection Mold Over Injection Mold Insert Injection Mold In Mold Decoration Liquid Injection Molding Metal Injection Micro Molding EMI Shielding Contract Assembly Optical Lens & LED Blow Molding Contract Mold Manufacture Silicone & Rubber Products 【Engineering】 Design and Development Partner Rapid Prototyping Tooling Soft Tooling Process Optimization

Waste Material Recycling Equipment at K 2022 | GENOX

It was a great honor for PRM-Taiwan to invite Jamie Jiang — the Marketing Director from GENOX. In the interview, we talked about the macro economic market during the pandemic, and the forecast for the future. In the end, Jamie also mentioned that the K Show is a worldwide exhibition for partners from the Plastic & Rubber industry, people can gain the newest industry information at the show.

PK-90CSV MHB Single Head Single Station View Stripe Blow Molding Machines | PARKER

Fully electric model machines are available.

Medical spiral tube extrusion machine line (double output ) | Everplast

Medical spiral tube extrusion machine line (double output ) The medical tube, made by food-grade materials, with the advantage of high transparency, good elasticity, good fluidity and corrosion resistance, suitable for medical, pharmaceutical and food production of gas and liquid delivery pipes, etc. -Contact Info: Twitter: / everplast Facebook: https://reurl.cc/r1LZb Web: https://www.everplast.com.tw/ Tel: +886-2-2289-7271 / +886-6-201-4846 Fax: +886-2-2289-7282 / +886-6-201-4290 Email: [email protected]

Vacuum Molding Machine | LIN CHENG

Vacuum Molding Machine - Oil Seal Vacuum Molding Machine- LIN CHENG Specializes in Vacuum Molding Machine, Lin Cheng Technologies Co., Ltd. was established in 1978 and has a strong professional team to manufacture Vacuum Molding Machine. A series of services we can provide ranges from the purchase of machines to the design and development of molds. Our Vacuum Molding Machine products are used for electronic components, car parts, oil rings, and so on. In 1997, we were granted the ISO 9002 quality certification.

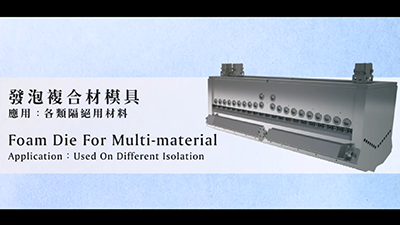

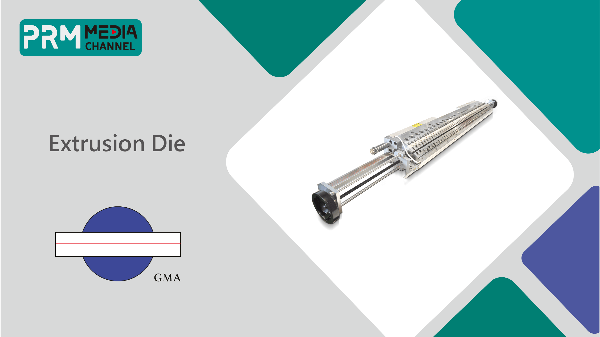

Extrusion Die - Foam Die For Multi-materials | GMA

Extrusion Die - Foam Die For Multi-materials | GMA Offers a variety of extrusion die. GMA MACHINERY ENTERPRISE was established in 1989. GMA specialized in extrusion die, T-Die extrusion, feedblock, melt pump, screen changer, slot die, vacuum box, air knife, static mixer. To meet extruding processor requirements, in 1990, GMA became involved in T-die design and manufacturing for sheet, film and coating film production. Over the years, we have invited several high molecular masters and doctors to research and develop various T-die manufacturing technology. GMA extrusion die, T-Die extrusion, feedblock, melt pump, screen changer, slot die, vacuum box, air knife, static mixer, GMA products have been sold to worldwide markets, such as: the U.K., Japan, the U.S.A., Italy, Brazil, Argentina and China, etc. We can offer best quality which can reach American and Japan level.

Full Range of Film Processing Machinery at K 2022 | JINMING

PRM was pleased to have a short interview with Simeon Wang, Vice President of Jinming Machinery, at K 2022. By interviewing with Mr. Wang, we have obtained the information about MDOPE solution, which was launched in recent years, to enable the stretch of the film manufactured from its machine. Moreover, Mr. Wang has expressed how Jinming solved the clients’ problems by its automatic technology during the pandemic. In the meanwhile, he also shared his observation of sustainability and expectation of the market in the post-pandemic era.

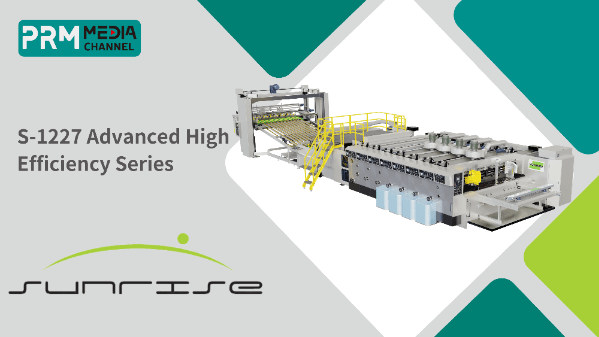

SUNRISE | S-1227 Advanced High Efficiency Series

Going beyone the traditional fixed type designs, effectively achieving noise reduction and dust prevention. Production speed up to 250 pcs/minute 15,000 pcs/hour.

Extrusion die and peripherals manufacturer | GMA

Founded in 1989, the GMA Machinery Enterprise Co., Ltd. (GMA), an R&D team composed of senior design engineers and technicians with decade’s strong experience in sheet and film extrusion equipment and auxiliary parts, has been devoted to providing custom products based on customer requirements. With 30 years of continuous efforts, it is the one of the best manufacturer in the world. Based on comprehensive processing equipment, GMA is able to exercise strict quality control throughout the whole in-house process from product design, manufacturing, assembling and inspection which, in turn, has earned customers’ continuous recognition and praise.

Campaign Video|EG-8002 Duplex Center Winding Slitter Rewinder|Nicely

Nicely is preparing to showcase our expertise globally. Our standout model is the EG-8002 Duplex Center Winding #slitterrewinder for #label #paper #processing. With advanced technology, superior tension control, and versatile #automation, it handles diverse #materials seamlessly. Nicely focuses on delivering tailored solutions, offering customized slitter rewinders, automation upgrades, and control system modernization. Each step of our process is carefully designed to address specific customer needs while aligning with the latest industry trends.

2024 CHINAPLAS Interview | King Plus

They are the manufacturer of blown film machines. In the past thirty-five years, Han King has relentlessly accumulated vast experience, from manufacturing mono-layer machines to two-layer, three-layer, and five-layer machines. We develop and produce our rotary die, embossing device, 360-degree oscillating haul-off, internal bubble cooling system, automatic air ring, and other blown film machine components.

Single-stage Injection Stretch Blow Molding Machine | GOLFANG-

Golfang treasures what have been entrusted... customizing special machine with molds for each customer. Golfang specializes in the development and manufacture of " single-stage injection stretch blow molding machine". Provide customers with a whole set of production equipment which includes customized machine and mold. Strictly control the quality and reliability of all assembly parts. Do the test runs repeatedly including mold testing and material testing before delivery. Obtain the most stable molding parameters based on the molding characteristics of the plastic specified by the customer and the adjustment during the bottle production. Meet the customer’s quality and production capacity requirements. Finally, after the machine acceptance, transfer the molding technique to the equipment user and do the personnel training. The equipment ca be run in full-time production with durability, high-efficiency, and high-stability, which creates the best return on investment for the customer. It is also the first choice for producing high-end plastic packaging containers when small quantities, varieties, and high quality are required at an early development stage. The Golfang team has accumulated many years of experience in the field of plastic product: PPSU baby bottles, PC/PMMA lampshades (LED light bulbs), HIPS yogurt bottles, PP/PE/PET medicine bottles, TRITAN water bottles, PET/PETG cosmetic bottles, household product bottles, etc... exquisite packaging containers. Also cooperated with the customers in developing products for well-known brands, include Pigeon, AVENT, Nuby, Yakult, Unilever, LOREAL, AVON, SHISEIDO, Pfizer, etc. Mold development is nothing more than a solution to product market demand. In the field of injection blow molding, Golfang insists on research, design, and manufacture of exclusive molds, and never relies on others, because we know that molds are designed and developed in response to the equipment. When customers evaluate and launch new product according to the market trend, what they need is stable quality and the chance to get ahead of the game. Therefore, with Golfang’s established and mature molding technique, whether it is the mold’s durability (2 million cycles guaranteed) or the delivery time, Golfang is always the most reliable choice for the customer. The common design of mold bases and mold parts is able to save mold costs and improve competitiveness for the customers. It provides them with the most economical solution. Golfang would communicate on product sizes beforehand and suggest for minor alteration. In such a way, Golfang gains good recognition from the customers.

Company Profile of Parker Plastic Machinery | PARKER

PARKER PLASTIC MACHINERY CO., LTD., established in 1989 in Taiwan, is a leading manufacturer specializing in turnkey solutions for blow molding machines. We offer a comprehensive range of high-performance extrusion equipment capable of handling capacities from 5cc to 220L drums. Our commitment to precision and reliability ensures that we consistently meet the diverse needs of our global clientele with excellence. At PARKER, we provide complete technical support, from initial consultations and customized training to ongoing service. Our expert team analyzes production requirements, conducts detailed project studies, and excels in comprehensive blow mold plant planning, optimizing operations for efficiency and profitability. Recognized for superior product quality and exceptional after-sales service, PARKER PLASTIC MACHINERY CO., LTD. has cultivated trusted partnerships spanning over 35 years. Our dedication to excellence is backed by stringent ISO certifications and rigorous internal controls, ensuring consistently high standards. We prioritize customer satisfaction through dedicated support, adding substantial value to our enduring relationships. PARKER continues to innovate in the blow molding industry, advancing technology to enhance machine performance globally. Our machines are trusted across 5 continents and over 113 countries. Our professional sales and service engineers provide prompt and reliable support to meet your needs. PARKER - your trusted partner for high-quality blow molding machines in Taiwan.

PVC Medical Tube Extrusion Machine Line (High speed type+Dust proof) | Everplast

The medical tubes produced by Everplast's medical tube extrusion machines have excellent quality and accuracy. They use advanced manufacturing technology and precision machining processes to ensure that each medical tube has accurate dimensions and uniform texture, complying with the strict standards and standards of the medical industry. specification. Whether used for infusion, drainage, or other medical applications, these tubings provide reliable performance and safety. Meets the strict quality and specification requirements of the medical industry. *Contact Info: Web: https://www.everplast.com.tw/ Facebook: https://reurl.cc/r1LZb YouTube:https://www.youtube.com/channel/UC_ziI3cDyRGjV71s8YkV-pg 1.https://www.everplast.com.tw/product/machine-line/medical-tube-machine-line/ 2.https://www.everplast.com.tw/product/machine-line/ 3.https://reurl.cc/QeMrp0 Tel: +886-2-2289-7271 / +886-6-201-4846 Fax: +886-2-2289-7282 / +886-6-201-4290 Email: [email protected]

Blow Molding Machine | CHEN WAY

CHEN WAY machinery is a specialized manufacturer in Taiwan that keeps focusing on the customized R & D for blow molding machines since 1990. Our blow molding machine produces mainly hollow plastic vessels ranging from 20ML to 2000L. Every machine is tested rigorously according to the customer production requirement, this process ensures that every machine can run with its maximum effectiveness. [Products List] + Small Blow Molding Machine + Medium Blow Molding Machine + Medium Co-extrusion Blow Molding Machine + Large Blow Molding Machine + Supersize Blow Molding Machine + Double L-Ring Drum Blow Molding Machine + Semi-auto Stretching Blow Molding Machine

ABA Blown Film Machine (JC-ABA) | PLASCO

PLASCO's JC-ABA Series of 3-layer co-extrusion blown film lines are the ultimate economic and environmental solutions for multi-layer blown film production. 【Machine Spec】 Applicable Material: LDPE / LLDPE / MDPE / HDPE Screw Diameter (mm): "45/55", "50/55", "55/75" Film Layflat Width (mm): 800 / 1000 / 1200 Film Thickness (mm): 0.015-0.10 Extrusion Capacity (kg/hr): 100 / 160 / 250 【Application】 Express Bag Plant Bag Shopping Bag T-shirt Bag Laundry Bag Garbage Bag 【Company Intro】 PLASCO is a global industry leader in the design, manufacture, and supply of innovative plastic extrusion lines. They specialize in applying innovative engineering concepts to the design and manufacture of plastic extrusion lines with more than 30 year experiences.

Plastic Welding Machine at K 2022 | TAI YEN

By interviewing Mr. Tony, from Tai-Yen Industrial Co., at K 2022, we have a quick understanding or their solution and product series, such as High Frequency Plastic Welding Machine and Ultrasonic Plastic Welding Machine.

JAW FENG MACHINERY | PRM Media Channel Interviews at TAIPEI PACK 2020

PRM Media Channel glad to share our recent interview with JAW FENG MACHINERY at TAIPEI PACK 2020. Ms. Mary Kuo shared deep insight into the packaging industry not only for the Taiwanese market but also the global market. She mentioned the effects of the pandemic on the vacuum packaging machinery industry specifically. She also shared with us how the companies are affected based on their sizes. TAIPEI PACK is a prestigious exhibition for JAW FENG MACHINERY, the company attends the exhibition every year at the same booth location and showcases many different vacuum packaging machinery customized based on the various needs of the customers. We suggest that it is worthy to take a look at the interview video. Your opinions and questions are most welcomed in the comment section. Remember to subscribe to our social media channels for the forthcoming interview videos and similar videos!~