LATEST UPDATE

Plastic Injection Molding Innovations and Green Solutions | KING'S SOLUTION

Livestream time: November 20th at 19: 00 (GMT +8, Taipei) The Livestream that PRM Media Channel held with KING'S SOLUTION CORP. with the title of Plastic Injection Molding Innovations and Green Solutions brings you new insight into the injection molding machine industry. Remember to direct your questions in the live chat section, KING'S SOLUTION and PRM Media Channel will be replying to your questions. What are the challenges, trends, and innovations in the injection molding industry? How to sustain after-sales services during post-pandemic? What advantages LPM (Low-Pressure Molding) brings to the manufacturers compared to Epoxy Injection Molding? Do you also have similar questions like that or would like to learn more? Then we welcome you to watch the Livestream video on November 20th at 19: 00 (GMT +8, Taipei) 【VIDEO OUTLINE】 00:00 Opening 00:59 KING'S SOLUTION CORPORATION 02:00 "Green Solution, Machine Soulmate" Slogan 03:04 Why to customize the machines? 05:00 Customized Machine Series 06:00 Market Challenges and Successful Cases 10:38 5 Gallon PET Preform Injection Molding Solutions 12:35 Advantages of KING’S in 5 Gallon PET Preforms 16:16 Trends in Injection Molding Market 18:40 LPM Application Examples 23:00 LPM Method vs Epoxy Method 26:00 After Sales Services and Customer Relations 28:55 Message to Current and Potential Customers Know PRM Media Channel more on: PRM Media Channel Website: https://bit.ly/3uqdubs PRM Facebook: https://www.facebook.com/PRMMediaChannel PRM LinkedIn: https://www.linkedin.com/company/prm-taiwan/

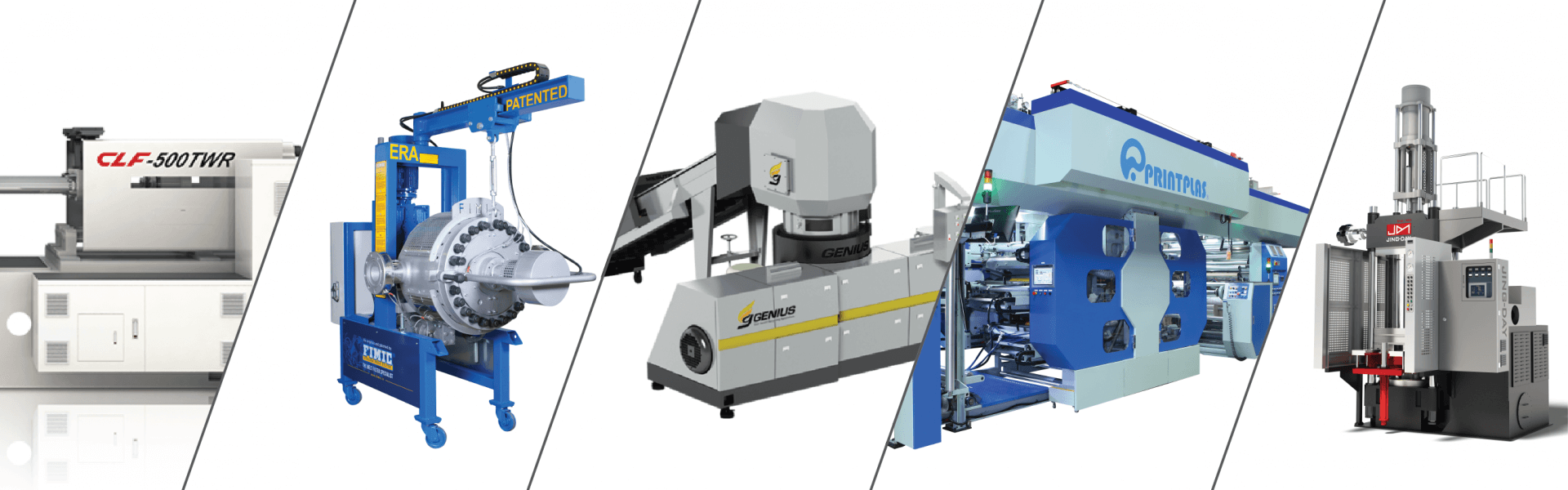

5G PET Preform Turnkey | KING'S SOLUTION

5G PET Preform Turnkey - 5 Gallon PET Preform Injection Molding Machines & Whole Plant Turn-Key Solution-pet-King's Machinery. FEATURES Select from 2, 4 or 8 cavities mold specifications. Single mold, 4 cavities design. The 2 stage material feed system raises the repeatability rate, lowers the cycle time, and boosts performance. When combined with a secondary cooling system, performance can be doubled. Temperature control via TSR raises temperature accuracy and, working with the accumulator, increases injection speed. Unique economical design is twice as energy efficient as comparable commercial units. we offer a complete set of 5 gallon PET bottle manufacturing equipment: raw material dehumidification and drying system; fixed-volume color additive; quickly stabilizing PET bottle preform molding machine; 4 cavity, hot runner mold; rapid cooling robot; and bottle blowing machine. From raw material to finished product stages, this all-inclusive system promotes high productivity, low cost, and superior quality-the bottle blowing defect rate is kept to a minuscule 0.5%. When water is shortage and lack of quality sanitary sewer, therefore, water container or bottle is convenience to filling in clean water and to carry with to the public. Moreover, bottle is not only for water-use but also oil-use even other liquid-use. King's gallon-size pre-form is one of the best choices in worldwide. Not only does save 20% of shipping cost but also decrease defect of blowing rate down to less 0.5%. And the most critical point is that any color is so clear by King's latest technology and 20 years PET knowledge.

5 Gallon PET Preform Turnkey Solution | KING'S SOLUTION

5 Gallon PET Preform Turnkey Solution | KING'S SOLUTION -------------------------------- MANUFACTURER: KING'S SOLUTION CORPORATION MODEL: KPET3200 ------------------------------- SPECIFICATIONS: 700g preform x 8 cavities 90 secs Cycle time 7,200 pcs/day