In the squeezed zone: Where is the future path of Taiwanese machine manufacturers?

As global interest rates continue to rise and armed conflicts persist around the world, the economic outlook for the plastics and rubber industry seems to be shrouded in uncertainty. One of the significant topics of discussion in the industry is the Global Plastics Treaty, currently under debate at the United Nations Environment Assembly(UNEA), where multiple countries are gathering to discuss ways to limit plastic production and address plastic waste.

Many manufacturers were worried about whether this would affect their business. However, the president of UNEA already mentioned the key point.

“This is not a fight against plastic; this is a fight against plastic pollution!” This was the statement by Espen Barth Eide (Norway), President of the UNEA that adopted the resolution to end plastic pollution. The distinction may seem straightforward, but the lines between “good plastic,” and “bad plastic” have not always been clear; nor have the lines between plastic (the material), plastics (the products), and plastic pollution (the waste).

The Multi Challenges Facing Taiwan's Plastics and Rubber Industry

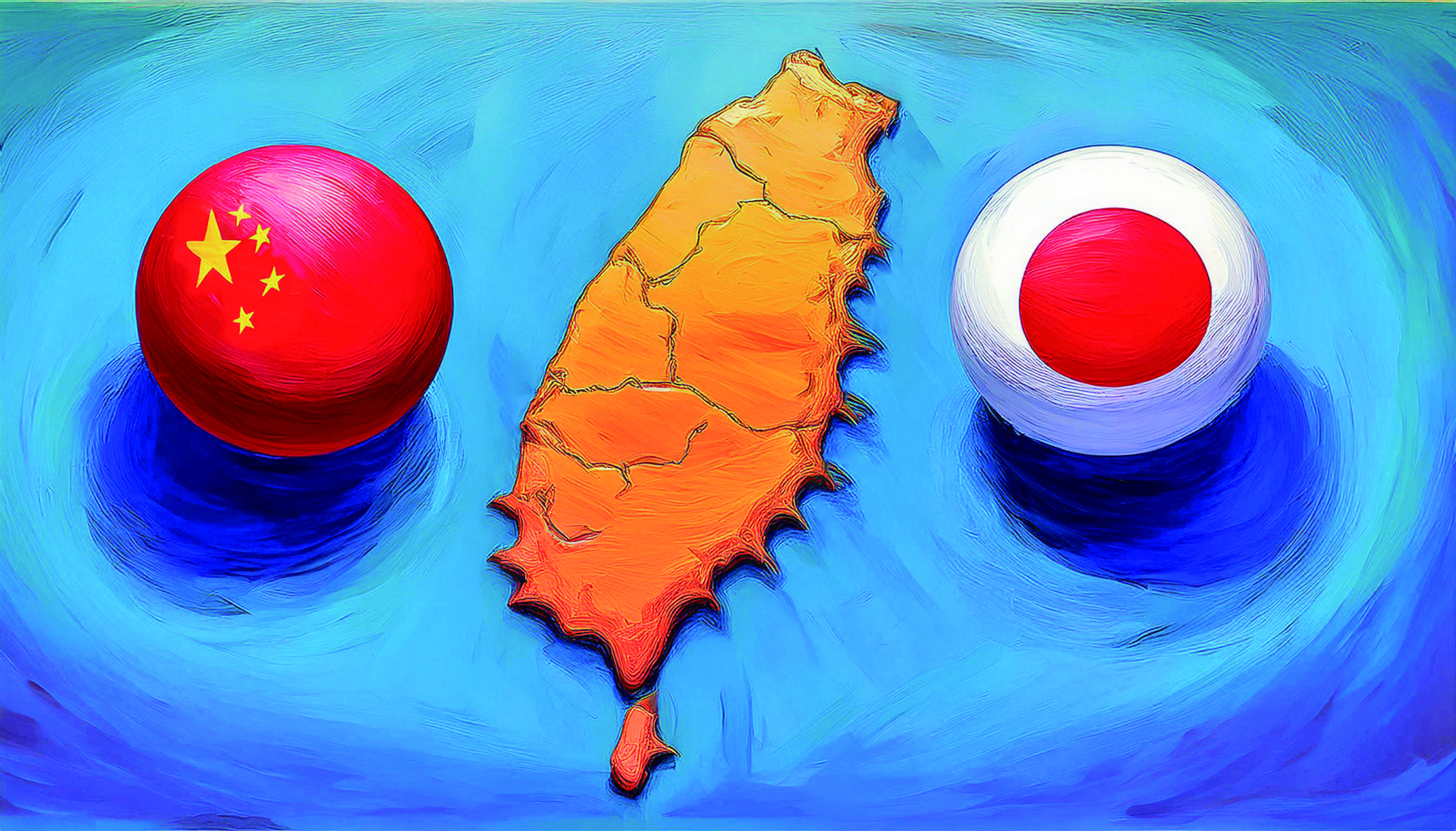

Taiwan's plastics and rubber industry is currently facing unprecedented challenges in the international market. The first challenge is the competitive pressure from China. Chinese-manufactured machinery has a clear price advantage, and its quality has improved significantly over the years through technological advancement and acquisitions with established companies. Taiwanese manufacturers find it increasingly difficult to compete on price, especially in the Vietnam and Thailand market. The PRM team participated in the VietnamPlas last year and Thailand Interplas this year, we can see the Chinese suppliers surrounding the Taiwanese’s manufacturers which is a horrible scene for them.

Another challenge is the continued depreciation of the Japanese yen from 2023 until recently, which has further complicated the situation for Taiwanese manufacturers. With the international market finding Japanese machinery more appealing, Taiwanese manufacturers face mounting pressure as their orders decrease, forcing them to retain existing customers while seeking new sources of business.

Highly Customization as a Way out of Morass

In such a challenging environment, Taiwan's plastics and rubber industry must find a way out. Many manufacturers rely on highly customized technology and services to stand out in the international market. Taiwanese manufacturers need to demonstrate an unmatched level of flexibility to meet the specific needs of different customers—an advantage that is difficult for competitors from other countries to replicate.

Thanks to Taiwan's robust education system, the industry has a strong technical foundation, allowing manufacturers to make frequent technological breakthroughs. This is exemplified by PRM's theme for this year: "PRM: Your Co-Pilot in Tech Advancements and Research." We aim to be the best partner for clients on the path to progress, helping them improve production efficiency and reduce costs through highly customized machinery and modular designs, thereby maintaining a leading position in the fiercely competitive international market.

Leading Internationalization: PRM is your Ally for Expanding Global Markets

In response to the globalization trend, Taiwan's plastics and rubber industry must continue to strengthen its internationalization efforts. Beyond diversifying export products, companies should focus on enhancing their market layout and brand image on the global stage. While participation in international trade shows has been effective, it's time to shift attention to online advertising as a powerful tool for global outreach. Platforms like PRM-Taiwan offer an excellent opportunity for companies to increase their visibility and attract international clients.

Establishing and regularly updating a professional official website is crucial for appealing to foreign customers. By refining their digital presence and embracing smart technologies, Taiwanese manufacturers can enhance production efficiency and product quality, meeting the diverse demands of various markets. Additionally, it's essential for companies to stay ahead of global environmental trends by investing in sustainable materials and technologies, positioning themselves advantageously in future market competition.

These strategies will not only boost the international competitiveness of Taiwanese companies but also open up new growth opportunities in global markets.

Embracing Challenges and Creating Opportunities

The challenges facing the plastics and rubber industry in 2024 are significant, but they also present an opportunity for Taiwanese companies to showcase their innovation and adaptability. By leveraging customized technology and focusing on international market strategies, especially in the digital realm, Taiwanese manufacturers can secure new footholds in the competitive global market and play a more prominent role in the global economy moving forward.