Classification : Vertical Injection Molding Machine

Country: Taiwan

Phone: 886-3-321-8768

Fax: 886-3-321-8769

Contact Person: Sheila Su

- Vertical direct hydraulic clamping system is designed for accurate, safe operation, especially suitable for insert molding.

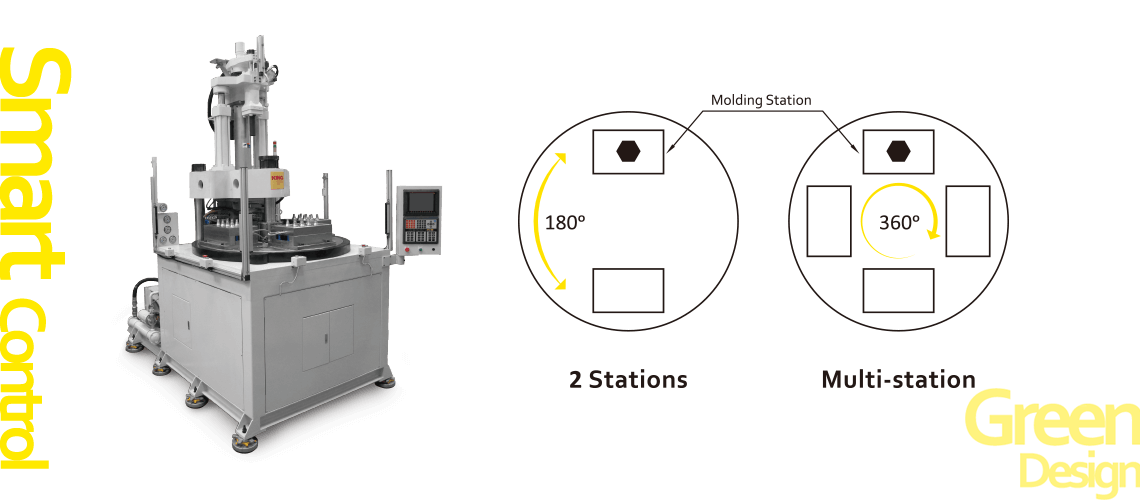

- With double slide table or rotary design, put-in, take-out products and molding finish at the same time, which is more safe and efficient for production , then reduce the cost of production.

- High precision mold platen ( Parallelism/ flatness : 0.02/100 mm), heavy-duty tie-bars, and low-pressure mold clamping work together to greatly extend machine & mold life.

- Nitride and NIP/ Nitroflon coated screws and barrels are long-lasting, robust and provide superior acid/alkaline resistance.

- Heavy-duty double cylinder injection unit is maintenance friendly and free of oil leaks.

- All series adapted Variable pump +PQ valves enable energy savings of 30~50%..

- Proportional hydraulic control system provides low noise, low energy consumption, and smooth machine movements with durable life.

- Low oil temperature, durable parts, high speed injection, and quiet operation.

- Controller can record the production conditions such as temperature, pressure, flow, position available on the panel, reducing adjust of machine.

- All machine with compact , space-saving design, reduce the heavy burden of the floor of factory.

| MODEL | K75-10DV-1 | K360-110-25DV-1 | K410-180-40DV-1 | |||||||

| Inj sys | ||||||||||

| Screw Diameter | mm | 24 | 28 | 30 | 22 | 28 | 34 | 26 | 32 | 40 |

| Injection Pressure | kgf/cm² | 1960 | 1440 | 1250 | 2330 | 1800 | 970 | 2330 | 1540 | 980 |

| Injection Capacity | cm³ | 38 | 52 | 60 | 46 | 74 | 110 | 74 | 113 | 176 |

| Injection Weight (PS) | oz | 1.56 | 2.1 | 2.4 | 1.9 | 3 | 4.4 | 3 | 4.6 | 7.1 |

| Injection Rate | cc/s. | 27 | 37 | 42 | 31 | 50 | 74 | 51 | 77 | 120 |

| Clamping sys | ||||||||||

| Clamping Force | tf | 10 | 25 | 40 | ||||||

| Clamping Stroke | mm | 200 | ||||||||

| Max. Mould Space | mm | 235 | 400 | |||||||

| Min. Mold Height | mm | 35 | 200 | |||||||

| Overall Size of Platens (H*V) | mm | 440*220 | 500*290 | 560*300 | ||||||

| Space Between Columns (H*V) | mm | 300 | 360*150 | 410*150 | ||||||

| Ejector Force | tf | 0.7 (2.7) | 0.7 (2.7) | 0.9 (2.7) | ||||||

| Ejector Stroke | mm | 21 (40) | 25 (40) | 40 (40) | ||||||

| Platen Moving sys | ||||||||||

| Moving Type | N/A | Rotary | Rotary | Rotary | ||||||

| Moving Plate Stroke | mm | 220 | 300 | 300 | ||||||

| Size of Moving Plate (H*V / DIA) | mm | ø600 | ø780 | ø880 | ||||||

| Stations | sets | 2~4 | 2~4 | 2~4 | ||||||

| Others | ||||||||||

| Drive Motor (with Variable pump) | kw(HP) | 3(4HP) | 3.7 (5HP) | 5.5 (7.5HP) | ||||||

| Heater | kw | 3.4 | 3.4 | 5.6 | ||||||

| Dimension of Machine (L*W*H) | m | 1.1 * 0.9 * 2.3 | 1.1 * 1.5 * 2.3 | 1.1* 1.5 * 2.3 | 1.6 * 1.2 * 2.7 | 1.6 * 1.5 * 2.8 | 1.7 * 1.6 * 2.8 | 1.8 * 1.4 * 3.0 | 1.8 * 1.7 * 3.1 | 1.9 * 1.8 * 3.1 |

| Weight of Machine | t | 0.6 | 0.8 | 1 | 1 | 1.2 | 1.4 | 1.6 | 1.7 | 2 |

| MODEL | K460-250-55DV-1 | K520-250-80DV-1 | K220-100DVR-1-S60 | |||||||

| Inj sys | ||||||||||

| Screw Diameter | mm | 31 | 38 | 44 | 30 | |||||

| Injection Pressure | kgf/cm² | 2471 | 1630 | 1210 | 0 | |||||

| Injection Capacity | cm³ | 106 | 159 | 213 | 99 | |||||

| Injection Weight (PS) | oz | 4.3 | 6.4 | 8.6 | 6.2 | |||||

| Injection Rate | cc/s. | 48 | 72 | 97 | - | |||||

| Clamping sys | ||||||||||

| Clamping Force | tf | 55 | 80 | 120 | ||||||

| Clamping Stroke | mm | 200 | 250 | |||||||

| Max. Mould Space | mm | 400 | 600 | |||||||

| Min. Mold Height | mm | 200 | - | |||||||

| Overall Size of Platens (H*V) | mm | 610*400 | 700*560 | - | ||||||

| Space Between Columns (H*V) | mm | 460*240 | 520*300 | - | ||||||

| Ejector Force | tf | 0.9 (2.7) | 0.9 (2.7) | 4 | ||||||

| Ejector Stroke | mm | 40 (40) | 50 (50) | 160 | ||||||

| Platen Moving sys | ||||||||||

| Moving Type | N/A | Rotary | Rotary | - | ||||||

| Moving Plate Stroke | mm | 350 | 350 | - | ||||||

| Size of Moving Plate (H*V / DIA) | mm | ø980 | ø1200 | - | ||||||

| Stations | sets | 2~4 | 2~4 | 2 | ||||||

| Others | ||||||||||

| Drive Motor (with Variable pump) | kw(HP) | 6 (8HP) | 6 (8HP) | 15 | ||||||

| Heater | kw | 6 | 6 | 9 | ||||||

| Dimension of Machine (L*W*H) | m | 2.0 * 1.6 * 3.2 | 2.0 * 1.9 * 3.3 | 2.1 * 1.9 * 3.3 | 2.2 * 1.8 * 3.4 | 2.2 * 2.1 * 3.5 | 2.4 * 2.4 * 3.5 | 2.6 * 1.5 * 3.5 | ||

| Weight of Machine | t | 2 | 2.3 | 2.7 | 2.2 | 2.6 | 3.2 | 6 | ||