Issue 117

Subscribe Now

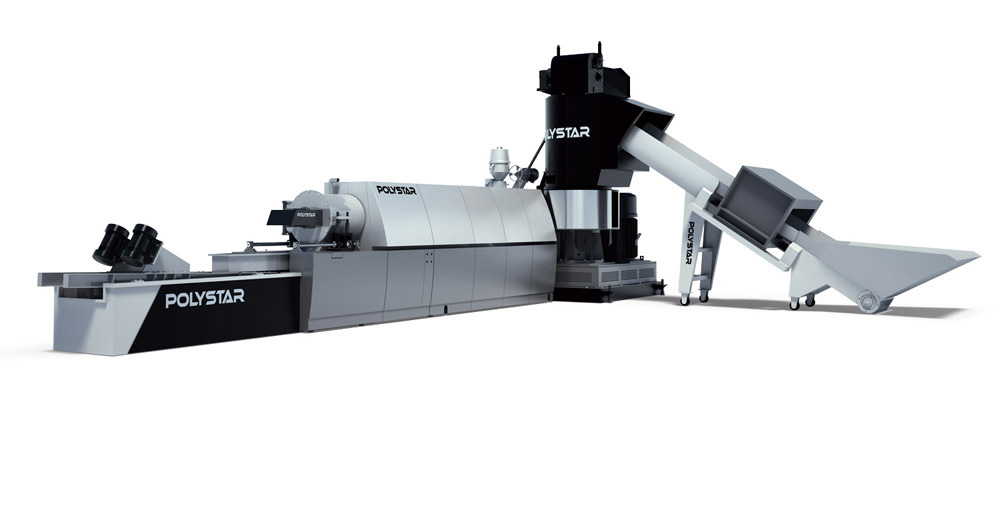

POLYSTAR- PE/PP Stretch film Recycling Machine

|

|||

|

1. Cutter compactor for faster and more stable material feeding. An improved design of the cutter compactor now works superbly with stretch film scrap. The compactor cuts, dries and compacts the material that enables a fast and stable feeding from the compactor directly into the extruder. 2. Degassing with vacuum pump ensures a superior degassing effect, providingExcellent quality pellets from even heavily printed material. 3. Minimal changes in MFIEnsures high loading of recycled pellets in the tape extrusion process with excellent tensile strength and elongation. 4. Additive feeder for adding master batch and compoundsThis feature is very helpful in homogeneously blending the recycled polymer melt with color master batch or additive master batch to give the desired quality to the recycled pellets.

|

|||

|

|||

|

More Information on PRM: http://www.prm-taiwan.com/com/polystar.html Official Website: http://www.polystarco.com |

|||

|

E-News Categories

Extruders and Extrusion Lines

- Air Bubble Film Extrusion Line

- Air Bubble Film Extrusion Line

- Air Bubble Sheet Co-extrusion Line

- Bag Making Machines

- Blow Film Making Machine

- Blown Film Extruders

- Blown Film Making Machine

- Cast Film Machine

- Coating Machine

- EPS/EPE Foam Sheet Extrusion Lines

- Extruder

- Extrusion Laminating Machines

- Extrusion Lines For Filaments and Yarn

- Extrusion Lines For Pipes and Profiles

- Monofilament Extruding Machinery

- Monofilament Extrusion Line

- PET Strapping Band Extrusion Lines

- Plastic Bag Making Machines

- Plastic Film Co-Extrusion

- Plastic Pipe Making Machines

- Plastic Tube Making Machine

- PVC Hose Making Machine

- Straw Making Machines

- Twin Screw Extruder

- Twin Screw Extruders

- Woven Bag Making Machine

Plastic Recycling Machinery

- Bottle Washing Line

- Crusher

- Granulators

- Pelletizer

- Pelletizers

- Pelletizing Machines

- PET Bottle Recycling Line

- PET Hot Washing Line

- Plastic Pelletizing Machines

- Plastic Recycling Equipment for Preprocessing

- Plastic Recycling Machines

- Plastic Waste Recycling Machine

- Recycling Lines

- Recycling Machine

- Shredders

- Squeezers

- Washing Lines

- Waste Recycling Equipment