Central Safety Filters

Categories : Loaders and Conveyors

SCSF series central safety filter in central loading system adopts large dust collector to filter dust and small impurities in material so can effectively protect blower and prolong its service life. Self-cleaning function realize the effective cleaning of the filter by set-up auto timer, which can reduce manual clean times. Equipped with vacuum breaking valve to not only protect the blower, but also accelerate conveying and loading speed.

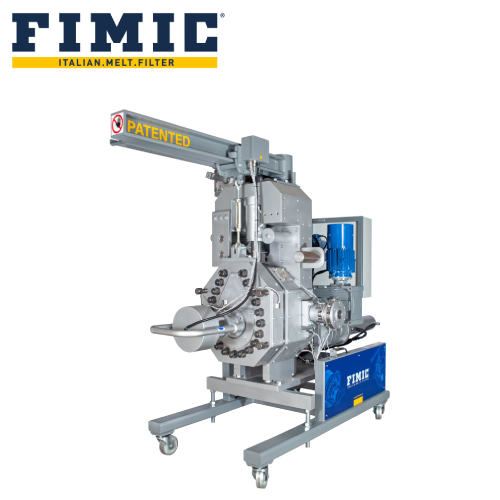

EXCLUSIVE MELT FILTER- GEM

Categories : Plastic Pelletizer Machines

Differently from RAS, this model reaches a greater filtering surface due to the presence of two filtering meshes towards which all the melt is directed, alongside two scrapers and independent discharge valves. The two blades scrape the contamination the filter collects, while the blade holder rakes it in to automatically eject it through the valve. The pressure mode can be set from the touch screen, while the blade holder rotating speed is adjustable and the valve only opens on a full cycle. In the event of a higher degree of contamination, a continuous mode is available to let the blade holder scrape continuously. In this case, a temporizer will tell the valve when to discharge. FIMIC- Screen changers Filters Filter Recycle filter Recycle filters Recycling Filter

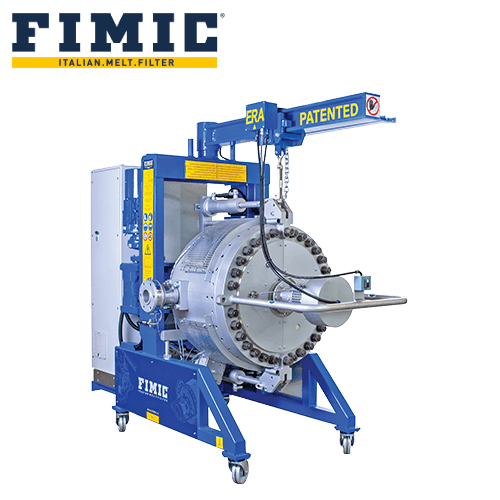

Automatic DOUBLE FILTER- ERA

Categories : Material Processing Machines

ERA is made of two internal filtration chambers and two independent discharge valves, thus enabling to setup a pre-filtration on the first step and a finer one in the second, all in the same machine! This means, in short, the possibility of using cheap punched screens (400-2000 micron) to protect the expensive laser screens (100-300 micron) coming afterwards. The resulting cost reduction is undeniable, both on the financial and energetic side. FIMIC screen changers Filters Filter Recycle filter Recycle filters Recycling Filter

Automatic Melt Filter - RAS+REF

Categories : Plastic Waste Recycling Machines

The melt filter that made FIMIC technology renowned in the recycling field, enhanced with the possibility to work in backflush. RAS+REF melt filters can in fact operate in two different ways: in scraping mode or in backflush mode, providing more options to anyone wishing to process materials with mesh filters. REF therefore represents an ideal option for mesh processing with exceptional final results. FIMIC - Screen changers Filters Filter Recycle filter Recycle filters Recycling Filter

AUTOMATIC MELT FILTER- TEN

Categories : Plastic Pelletizer Machines

TEN is FIMIC’s automatic screen changer capable of blocking even the smallest contamination particles thanks to its mesh, whose resistance allows to adapt the temperature according to the requirements and the material to be processed. The adjustable opening on the mesh output is a further guarantee of the quality of the end product. A small scraper close to the mesh harvests most waste and prevents it from breaking when it is changed. Its 1.465 cm2 filtering surface has a low load pressure; it therefore excludes any danger of degradation. It is also possible to adjust the mesh changing speed, setting a target pressure at which it will be automatically switched, to fit all the workflow to the material to be filtered. Furthermore, when changed the mesh is held by the material pressure itself and doesn’t needany other auxiliary systems. The mesh proper is available in varying filtration levels, starting from 80 micron / 170 mesh. TEN can also be adapted to finer filtration levels equipping custom made meshes. Quick opening is also always guaranteed. There’s no need for dedicated tools or skills, for FIMIC provides a pneumatic screwdriver at the time of purchase. FIMIC - Screen changers Filters Filter Recycle filter Recycle filters Recycling Filter

Automatic self-cleaning screen changer - RAS

Categories : Plastic Waste Recycling Machines

Any contamination the filter collects is scraped from its surface by two blades, and then gathered by the blade-holder. Finally, anything harvested is automatically ejected through the front valve. Another important feature is the possibility to determine a pressure set-point (in pressure mode) with nothing more than a few taps on the touch screen, so that once such level is reached the blade holder (running at adjustable speed) will proceed to gather the contamination, opening the front valve only on a full cycle. In the event of a particularly contaminated input material, the filter cant be set to work in continuous mode: the blade holder will keep on scraping, while relying on temporized valve openings to discharge as needed. FIMIC- Screen changers Filters Filter Recycle filter Recycle filters Recycling Filter

Water Transfer Printing Dipping Machine- Semi-Automatic- YHT-222AX

Categories : Hydrographic / Water transfer Machines

YHT-222AX is 2 meters standard dipping machine with production arm which can dip various shapes of parts both manually or use production arm; and this machine also includes an auto spray system, working with both systems provide stable quality to the final product. The temperature controlled tank meet the medium volume requirement. High durability of tank structure with heavy loading production arm and water circulation by dual filters system are the best working tool for your Water Transfer Printing business. This transfer printing machine is perfect for large product and medium quantities of production/day.

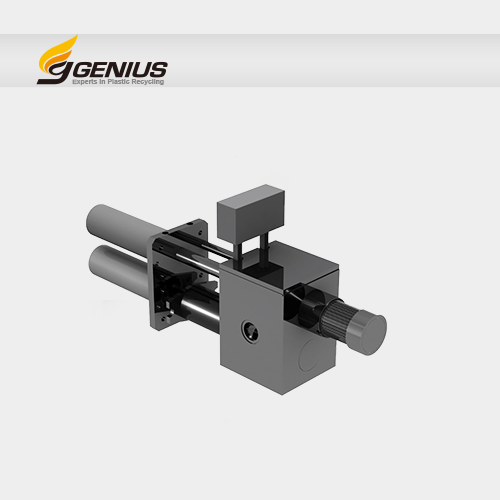

Dual-Piston Filter

Categories : Screen Changers / Filters

Bigger Filtration Area, Less Frequent Mesh Change Compared to the slide type product, the dual-piston filters have a larger filtration area which reduces the frequency of changing the mesh and the labor cost. Non-Stop Dual-Piston Filter The dual-piston filter is made in a continuous style with two filter flows. There is at least one filter working when the screen is changing. The piston moves slowly when the mesh is changed. This allows the melted polymer to be filled in the filter area gradually to ensure low fluctuation of the extrusion pressure. GENIUS

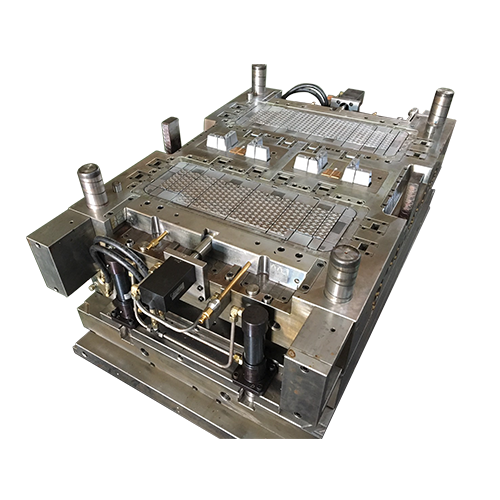

Rattan Mold

Categories : Injection Molds

Applications: Air filters Closet Hangers Toilet Stool Mold size: 990W x 1720L x 860H mm Mold weight: 9500kg Injection machine: 1000TON