ISSUE 261 Subscribe Now

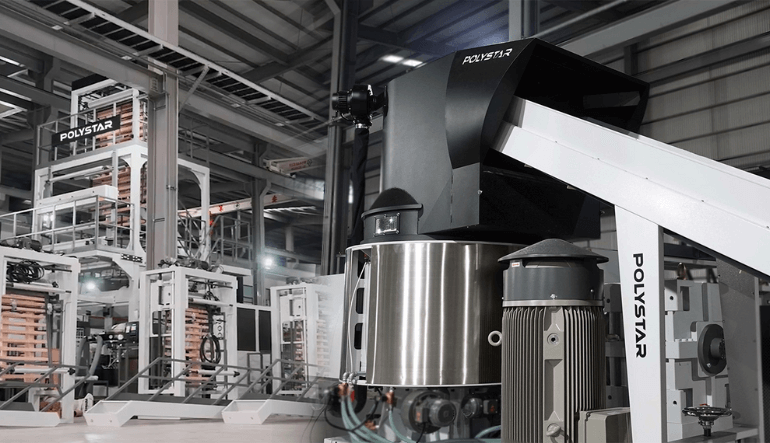

POLYSTAR Co-extrusion & Recycling: Making Plastic Film Sustainable

With the increasing concern over plastic waste and pollution, plastic bag manufacturers are looking for more sustainable production methods to diminish the negative effects of their plastic products. Co-extrusion and recycling are two techniques that are gaining popularity in the plastic film industry. In this blog, we will explore how co-extrusion and recycling can create a circular economy for plastic bag production and minimize waste.

LATEST UPDATE

Plastic Recycling Hero Behind the Scenes, Geording Machinery Becomes a Trusted Manufacturer with Customization Capabilities

Plastic waste recycling has long been a symbol of green sustainability. With the rapid advancement of recycling technologies, applications have become increasingly diverse and abundant. The World Economic Forum predicts that by 2030, the global circular economy will reach $4.5 trillion. Internationally, there are new applications emerging, such as environmentally friendly building materials made from PET bottle bricks and eyeglass materials made from discarded fishing nets. Coca-Cola Taiwan has also invested significant research and development efforts, spending seven years to develop products using 100% recycled plastic bottles, setting a new milestone in plastic recycling applications.

Full Shine Machinery's Expertise in PC Water Bottles Making Machine

Full Shine Machinery has 30 years of experience specializing in Automatic Blow Molding Machines, Multi-layer Co-extrusion Blow Molding Machines (2-6 layers bottle), Accumulator-head Blow Molding Machines, One Stage Injection Blow Molding Machines, and PET Stretch Blow Molding Machines. In addition, we have experience with Molds, Die Heads, and Auxiliary Equipment. Please contact us to learn more about our capabilities.