Issue 153

Subscribe Now

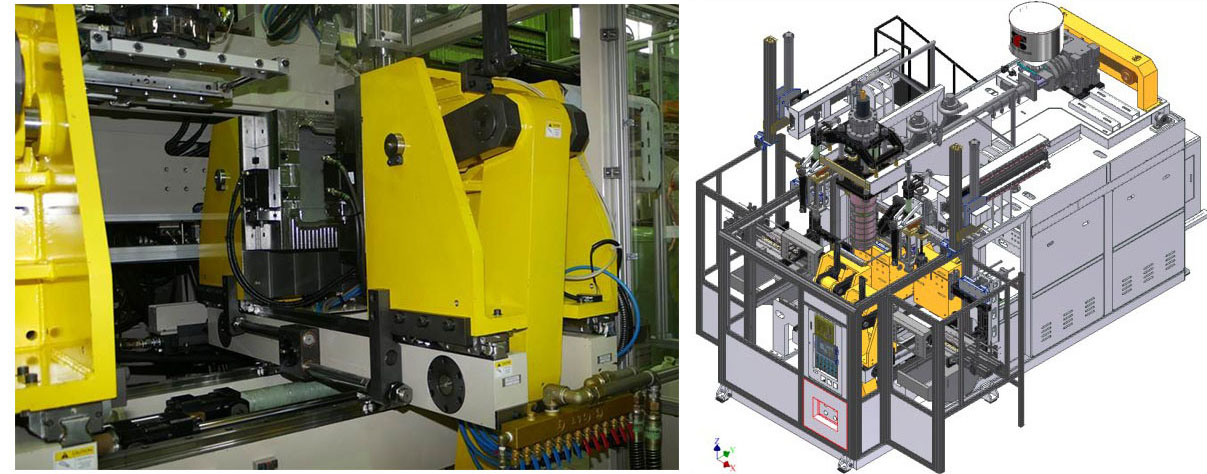

AUTOMATION TECHNOLOGY OF FULL SHINE BLOW MOLDING MACHINERY

Full Shine has 27 years of experience in blow molding machine industry and always improves our worldwide customers' processes, productivity and capacity by suitable machines. Our state-of-the-art blow molding machine- FS-100PSDO (customized design) with curved arms for strong mold clamping, equipped with linear slide guide way, made in Germany for swift movement, screw drive in the control of direct-mounted gear box and Inverter motor as power saving feature, single die-head & double station. This machinery is also with the concept of offering user-friendly design, easy operation, durability and less maintenance.

With pursuit of high production efficiency and less labor work, FULL SHINE’s blow molding machine is capable of fast accumulation. Not only the high production, but also our feature of robot automation, which is came with auto deflashing system, auto jar neck cutting/leak testing, auto recycling system. Not only central material supply system is equipped, but also Full Shine can design the inner labeling machine for customization. To achieve the target of the intensive and complete production line, therefore the labor work could be reduced hugely.

To save your total expense, FULL SHINE designs the energy-saving system by incorporating with Yuken-Japan servo drive system for carriage as energy-saving, providing the efficient power saving: 30-60%. With new slide-column clamping design for strong mold clamping, the carriage movement is under the digital linear transducer control, which is more precise and accurate to ensure the molding performance in the exact positions and times. However, the investment in automation is always mistaken to be a cost of great fortune. Nowadays, the automation technology is not out of reach anymore since it has become more mature and cost effective. The investment is paid off in a short time via practical way and arrangement.

The blow molding machine also able to accompany with “In-Mold Labeling Machine” to put un-removable labels on both sides of the plastic container with special material forming together with the product. Good for identifying the authentic further to secure branding. The labeling system controlled by computer programming setting makes the label position 100% same of each cycle. 3-dimensional robot arms also offer efficiency and offer a safe working environment for the operator.

Full Shine keeps running principle consistently -“Think globally, footing locally, Active & Creative, Enjoys challenge, Brand Marketing, and Constant Operation”. To prospect the future, we set our sights on stable quality of present products, research and develop new technologies and design, expand the foreign market. Full Shine will keep innovation and bring a more flexible machine in the near future.

For more information, please visit our website: www.full-shine.com

or please email to : [email protected]

or please email to : [email protected]

.png) |

Official website https://www.full-shine.com/en/index.html Full Shine in PRM-TAIWAN https://www.prm-taiwan.com/com/full-shine.html |