The Cutting Edge Of Technology

Within such a competitive and raised personnel cost setting, there’s a necessary need for us to seek high production efficiency and reduce manual work by using the fully automatic machine, automation reforms the way drastically we operate in plastic industry and becomes the inevitable trend. Fully automation not only can level up the production efficiency but more importantly it can save the enormous budget for the personnel cost.

In previous days, the automation investment might cost a lot, and not quite effective; nevertheless, it no longer be regarded as unreachable investment, it’s more mature and less cost nowadays.

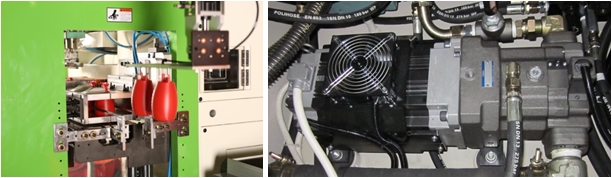

On The Cutting Edge Of Technology, Full Shine (TAIWAN) has escalated and applied the fully automation to our blow molding production. For thoughtful customization services, we provide different clients with bunch of optional devices, even modify the specification to complete their unique personal production line. For FS-55HDSO, the linear movement blow molding machine, which mainly produces high value-added medical products, for ideal production, we get rid of the unnecessary human labor involvement to satisfy by installing the smart robot system, it also makes sure the environment is completely clean during the process of production. From the process of fully auto deflashing, it carries out the finished product with the robot arm, placement and arrangement on trays and continually connecting to the next working station are no exception, operating by the robot system.

Making sure the products are perfectly well, the finished products are auto monitored, it saves the personnel cost. The technological innovation is connected firmly to the newly concept of industry 4.0, which is the most trendy high-tech and emphasize the production efficiency, speed and mobility. Once every part of machine has completely been set, it can fully run by itself, attributing to Auto Deflashing, Auto Jar Neck Cutting, Leak Testing, and Auto Recycling System for production automatically and Central Material Supply System equipped with the machine, to achieve the target of the intensive and complete production line.

For more information, please visit Full Shine website: http://www.full-shine.com/en/index.html ,

H Series Blow Molding Machinery: http://www.full-shine.com/en/products_sub_H-Series.html

, or e-mail to [email protected]

** 2016 HOT NEWS for FULL SHINE **

K-Show 2016, Dusseldorf, Germany

VENUE: Düsseldorf, Germany

EXHIBITION DATE: Oct 19~26, 2016

BOOTH NO.: Hall 12 A52-21

TIME: 10:00 – 18:30

LOCATION: Messe Dusseldorf, Germany

FOR MORE INFORMATION, PLEASE VISIT: http://www.k-online.com/

*************************

*************************

Welcome to Visit FULL SHINE at K-Show 2016

Full Shine sincerely invites you to participate in K-Show 2016, Full Shine is about to present the innovative approach and machine performance at Hall 12 A52-21 on K-Show 2016,

Messe Dusseldorf, during October 19~26. Provided you are interested in attending this international fair, kindly contact Full Shine directly for further support.

More information on PRM: http://www.prm-taiwan.com/com/full-shine.html

Official Website: http://www.full-shine.com/en/index.html