Issue 51

Subscribe Now

Plastivision India 2013 – Exclusive Interview

Exclusive Interview – Worldly Industry Co., Ltd.

The general manager of Worldly Industry, Klive Lai, has been to India for four to five times this year, and is very used to this market. Worldly has expanded its own business over the India, such as New Delhi, Mumbai, Chennai and Bangladesh, and these cities are the main market for Worldly. With the efforts in these years, Worldly has successfully entered the India market with its own brand. Facing the continuously growth of India, Klive confidently tells us that Worldly has fully preparation and looks forward to the future.

The Interviewee : Klive Lai, The General Manager of Worldly Industrial Co., Ltd.

Q1. This time in Plastivision India, what do you learn?

We have started the business in India since 1997, and think this market has much potential. This time, the Plastivision India exhibition is quite successful. Many visitors ask us more information after they understand the product. This situation increase the possibility of purchasing the product, and the reason might be that many famous local companies are our clients.

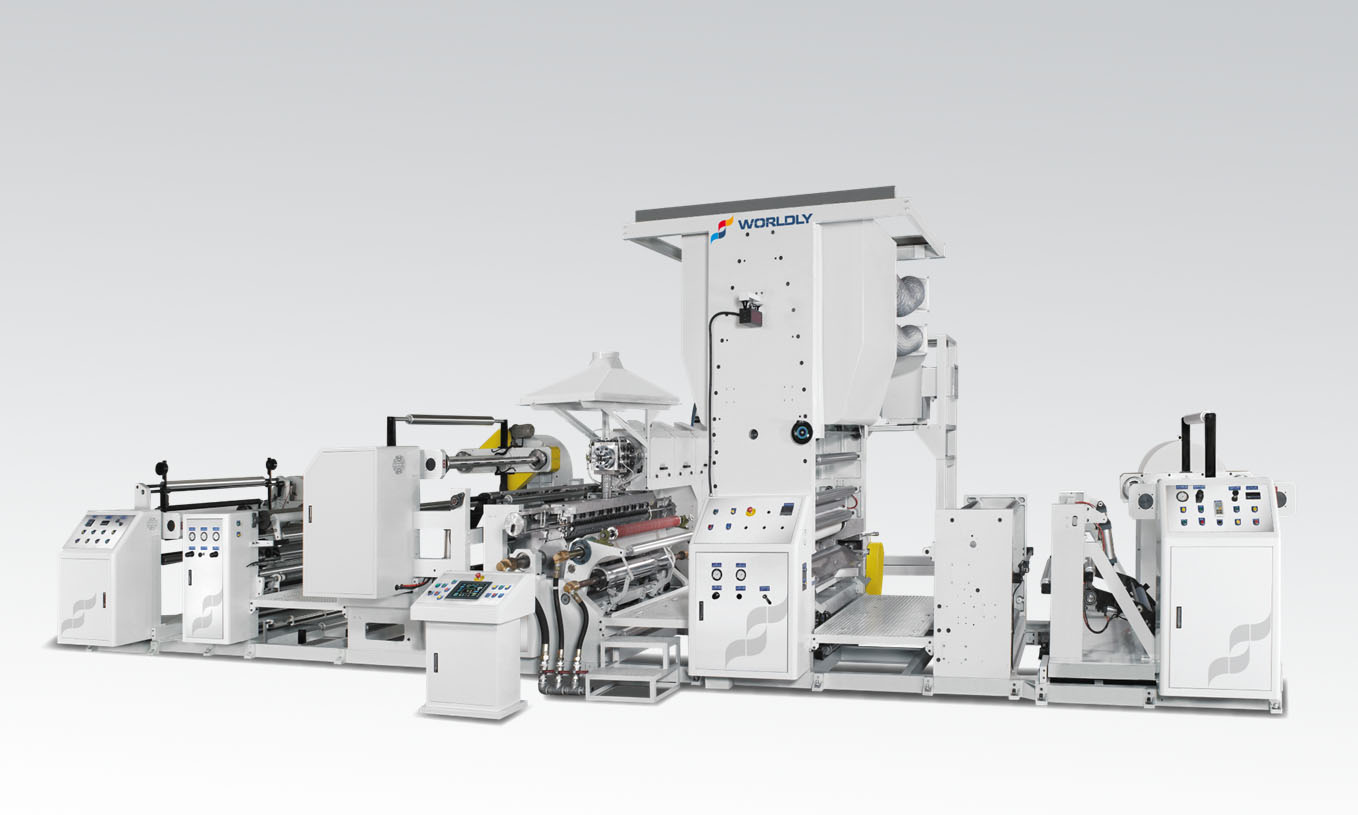

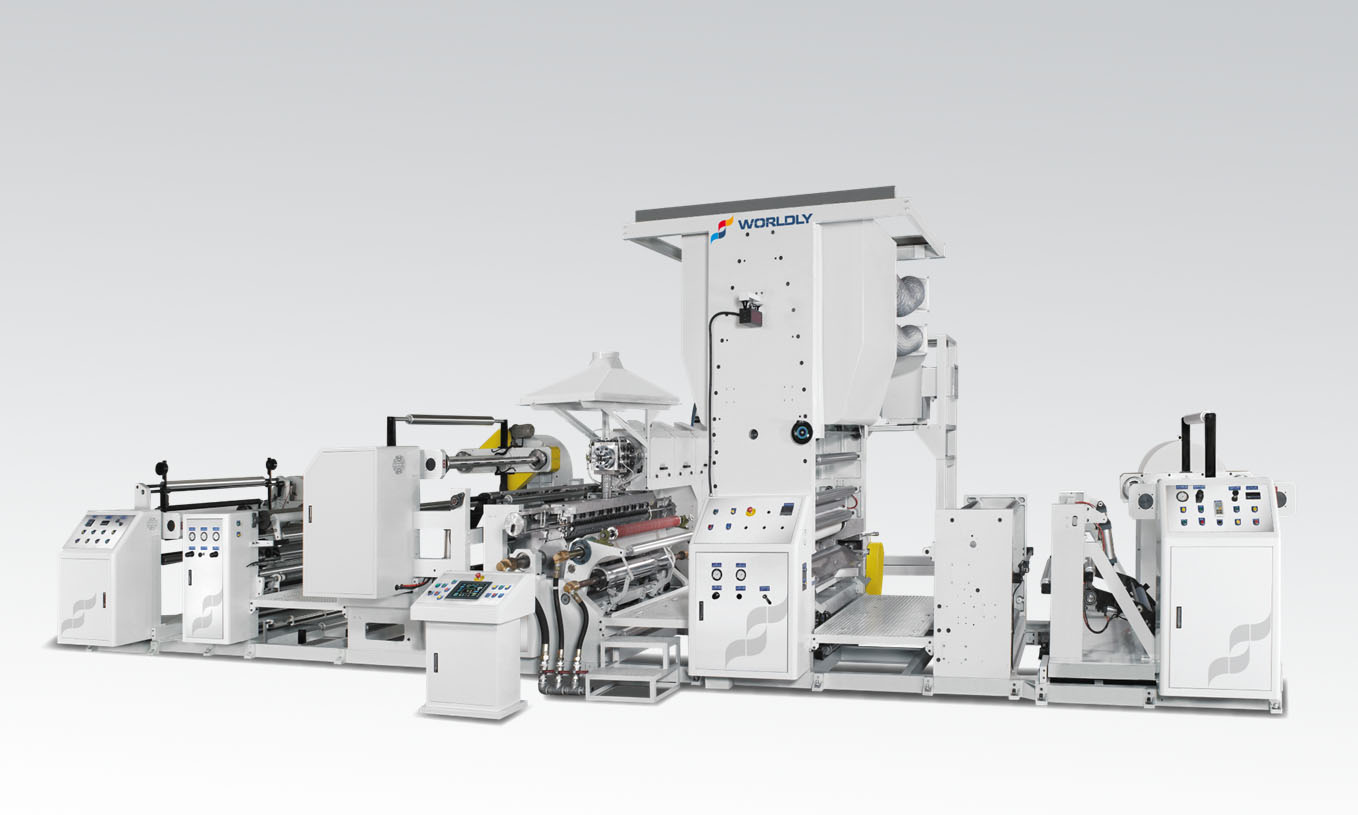

Q2. Could you introduce the main product of this Plastivision India?

We have a wide range of product, such as printing, laminating, coating, extrusion and packaging machinery. Especially the laminating and coating machine are very popular in India market. This time, our main product is a packaging technology “Aluminum Foil”, which has three processes “Printing” “Laminating” and “Coating”, and can be used for food and medical packaging. This is the difference for us from other competitors. Our main promotion is on laminating and printing machine.

Q3. What is your advantage for India customers?

Even though we price is higher than other India companies, our technology is better. There are many India companies producing same machine, but they cannot provide the same technology as we do. For Worldly, the factor of our brand is “Quality” and “Service”, and these factors are the target which we are working on. Every year, Worldly will have a world tour for serving the clients in different areas, and visit Bangladesh for more than two times. Helping buyers with solutions and teaching them to use our product are our biggest advantages.

Q4. Are you looking for agent in India or considering establishing a branch?

So far we have some trading companies to help us selling machines in India, but we have a very high standard on the technology and service. Therefore, we are looking for an agent in India.

Exclusive Interview – Jin Kuo Hua Plastic Machine Co., Ltd.

Jin Kuo Hua has been in this industry for about 60 years since 1956, and is the manufacturer of Continuous Mixer with Extrusion Pelletizing Liner, Soft PVC Compounding Line, High Filler Modify Compound Making Line, Soft PVC material for cable application, plastic pellet making line and EVA, TPE, TPR, PE, PP pellet producing line. Jin Kuo Hua can notice the trend of the market very fast, because they are the supplier of other manufacturers. And more, it also has Extruders, Plastic Composite Profile Extrusion Line and PVC Reinforced Hose Making Machine.

The Interviewee : Mr. Lee, The Manager of Jin Kuo Hua Plastic Machine Co., Ltd.

Q1. What do you think about this Plastivision India?

This is the third time for us to come to Mumbai for attending exhibition. Not only promoting our company brand, all the visitors at our booth are very familiar to our product. Comparing to other visitor before, this year visitors can get to the point, and we notice that the whole industry is improving.

Plastic and rubber industry is growing in India and has much potential. In the past, India buyers always choose product based on its price, but now they have changed their habit. They start to focus on the function and efficiency part of the machine. And the visitors understand this industry better. I think the exhibition in Mumbai is more professional than in New Delhi. Mumbai is industrial center, therefore, there are more feedback.

Q2. Could you introduce the most popular machine this time?

This year, many people are interested in recycling equipment, PVC and Soft PVC Compounding line. Because the demand of injection molding machine and blow film machine is increased, they need the compounding line which is stable and high production to make material. In this exhibition, we find out that plastic floor and plastic wood are rising up in India. Therefore, many people ask for the Wood Plastic Composite Profile Extrusion Line.

Q3. How do you provide the after-sale service in India?

Our machines perform very stable; as a result, we provide on-line service to our clients. Once they tell us the problem, we will solve the problem in time. With 60 year experience, we can provide the clients the most stable and best product.

Exclusive Interview –DIHZHOU Automation Technology Co., Ltd.

Dihzhou automation is founded in 1992, located in Taichung, Taiwan, and sets up a branch in Ningbo, China in 2005. It has distributed in Taiwan, Ningbo, Guangdong and Suzhou, and plan to expand in the future. With the motivation of having a strong and professional sales and technical support team, Dihzhou actively develops a complete controller, in order to provide comprehensive service. Dihzhou has its own R&D team, and have developed the following product: Horizontal Injection Molding Machine, Vertical Injection Molding Machine, Rubber Injection Molding Machine and Blow Molding Machine. It has focused on the market of plastic injection molding controller, and providing the software and hardware integrated system, customer- oriented service and technical support structure. Dihzhou is committed to be a leader of developing and manufacturing the high quality product for clients, and provides high-efficiency service to the automation market.

The Interviewee : Casey Liang, The Manager of Dihzhou Technology Co., Ltd.

Q1. Is this your first time to attend Plastivision?

We have attended both the 8th Plastivision India 2011 and IPLEX Chennai 2013. This time, the visitors in Taiwan pavilion is pretty much same as in the 8th Plastivision, but fewer people ask for the product. We think the depreciation of currency is the reason makes them think twice on the price of import product.

Q2. What are your main product and features?

This exhibition, we mainly promote EASY-3000、EASY-800 (EASY Series) and AF1000 (AF Series) injection molding machine controller. This is the product which is exclusive made for India market, and suitable for the India hardware design and other special software. Furthermore, this comptroller still has a same feature like other Dihzhou controllers. They are all very stable, fast and accurate.

Q3. What is your expectation on Dihzhou in the future?

In India market, we hope distributing more service bases in every important city, such as New Delhi, Mumbai, Chennai, Kolkata and Gujarat. So far, we have cooperated with some dealers, and launch Dihzhou controller into the India market and have very good feedbacks. Our target is to find more dealers and agents in the coming two years, and try to cooperate with India leading machinery companies, in order to increase the market share.

The general manager of Worldly Industry, Klive Lai, has been to India for four to five times this year, and is very used to this market. Worldly has expanded its own business over the India, such as New Delhi, Mumbai, Chennai and Bangladesh, and these cities are the main market for Worldly. With the efforts in these years, Worldly has successfully entered the India market with its own brand. Facing the continuously growth of India, Klive confidently tells us that Worldly has fully preparation and looks forward to the future.

The Interviewee : Klive Lai, The General Manager of Worldly Industrial Co., Ltd.

Q1. This time in Plastivision India, what do you learn?

We have started the business in India since 1997, and think this market has much potential. This time, the Plastivision India exhibition is quite successful. Many visitors ask us more information after they understand the product. This situation increase the possibility of purchasing the product, and the reason might be that many famous local companies are our clients.

Q2. Could you introduce the main product of this Plastivision India?

We have a wide range of product, such as printing, laminating, coating, extrusion and packaging machinery. Especially the laminating and coating machine are very popular in India market. This time, our main product is a packaging technology “Aluminum Foil”, which has three processes “Printing” “Laminating” and “Coating”, and can be used for food and medical packaging. This is the difference for us from other competitors. Our main promotion is on laminating and printing machine.

Q3. What is your advantage for India customers?

Even though we price is higher than other India companies, our technology is better. There are many India companies producing same machine, but they cannot provide the same technology as we do. For Worldly, the factor of our brand is “Quality” and “Service”, and these factors are the target which we are working on. Every year, Worldly will have a world tour for serving the clients in different areas, and visit Bangladesh for more than two times. Helping buyers with solutions and teaching them to use our product are our biggest advantages.

Q4. Are you looking for agent in India or considering establishing a branch?

So far we have some trading companies to help us selling machines in India, but we have a very high standard on the technology and service. Therefore, we are looking for an agent in India.

Exclusive Interview – Jin Kuo Hua Plastic Machine Co., Ltd.

Jin Kuo Hua has been in this industry for about 60 years since 1956, and is the manufacturer of Continuous Mixer with Extrusion Pelletizing Liner, Soft PVC Compounding Line, High Filler Modify Compound Making Line, Soft PVC material for cable application, plastic pellet making line and EVA, TPE, TPR, PE, PP pellet producing line. Jin Kuo Hua can notice the trend of the market very fast, because they are the supplier of other manufacturers. And more, it also has Extruders, Plastic Composite Profile Extrusion Line and PVC Reinforced Hose Making Machine.

The Interviewee : Mr. Lee, The Manager of Jin Kuo Hua Plastic Machine Co., Ltd.

Q1. What do you think about this Plastivision India?

This is the third time for us to come to Mumbai for attending exhibition. Not only promoting our company brand, all the visitors at our booth are very familiar to our product. Comparing to other visitor before, this year visitors can get to the point, and we notice that the whole industry is improving.

Plastic and rubber industry is growing in India and has much potential. In the past, India buyers always choose product based on its price, but now they have changed their habit. They start to focus on the function and efficiency part of the machine. And the visitors understand this industry better. I think the exhibition in Mumbai is more professional than in New Delhi. Mumbai is industrial center, therefore, there are more feedback.

Q2. Could you introduce the most popular machine this time?

This year, many people are interested in recycling equipment, PVC and Soft PVC Compounding line. Because the demand of injection molding machine and blow film machine is increased, they need the compounding line which is stable and high production to make material. In this exhibition, we find out that plastic floor and plastic wood are rising up in India. Therefore, many people ask for the Wood Plastic Composite Profile Extrusion Line.

Q3. How do you provide the after-sale service in India?

Our machines perform very stable; as a result, we provide on-line service to our clients. Once they tell us the problem, we will solve the problem in time. With 60 year experience, we can provide the clients the most stable and best product.

Exclusive Interview –DIHZHOU Automation Technology Co., Ltd.

Dihzhou automation is founded in 1992, located in Taichung, Taiwan, and sets up a branch in Ningbo, China in 2005. It has distributed in Taiwan, Ningbo, Guangdong and Suzhou, and plan to expand in the future. With the motivation of having a strong and professional sales and technical support team, Dihzhou actively develops a complete controller, in order to provide comprehensive service. Dihzhou has its own R&D team, and have developed the following product: Horizontal Injection Molding Machine, Vertical Injection Molding Machine, Rubber Injection Molding Machine and Blow Molding Machine. It has focused on the market of plastic injection molding controller, and providing the software and hardware integrated system, customer- oriented service and technical support structure. Dihzhou is committed to be a leader of developing and manufacturing the high quality product for clients, and provides high-efficiency service to the automation market.

The Interviewee : Casey Liang, The Manager of Dihzhou Technology Co., Ltd.

Q1. Is this your first time to attend Plastivision?

We have attended both the 8th Plastivision India 2011 and IPLEX Chennai 2013. This time, the visitors in Taiwan pavilion is pretty much same as in the 8th Plastivision, but fewer people ask for the product. We think the depreciation of currency is the reason makes them think twice on the price of import product.

Q2. What are your main product and features?

This exhibition, we mainly promote EASY-3000、EASY-800 (EASY Series) and AF1000 (AF Series) injection molding machine controller. This is the product which is exclusive made for India market, and suitable for the India hardware design and other special software. Furthermore, this comptroller still has a same feature like other Dihzhou controllers. They are all very stable, fast and accurate.

Q3. What is your expectation on Dihzhou in the future?

In India market, we hope distributing more service bases in every important city, such as New Delhi, Mumbai, Chennai, Kolkata and Gujarat. So far, we have cooperated with some dealers, and launch Dihzhou controller into the India market and have very good feedbacks. Our target is to find more dealers and agents in the coming two years, and try to cooperate with India leading machinery companies, in order to increase the market share.