POLYSTAR: Film Extruder with Twin Head – Efficient For Bag Production?

Film Extruder with Twin Head – Efficient For Bag Production?

Small Bags. Big Production.

Higher production for thin film and small-sized bags.

Higher production for thin film and small-sized bags.

Compared to extruders with single die heads, the double-die extruders can achieve higher production capacity when producing film rolls that are small in width, as the high extrusion output is dispersed into two separate channels of the die heads instead of one.

Designed for HD/LDPE Bag Producers.

The twin head blown film extruder is designed for bag producers to cover a wide range of products including: shopping bags, fruit and vegetable bags, perforated bags, flat bags, bottom sealed bags, bag-on-roll, die-cut (gift) bags, ice bags, kitchen bags, live seafood bags, T-shirt bags (both hot and cold cutting type), dog poop bags and many others.

Productive for All sizes. Flexible in production.

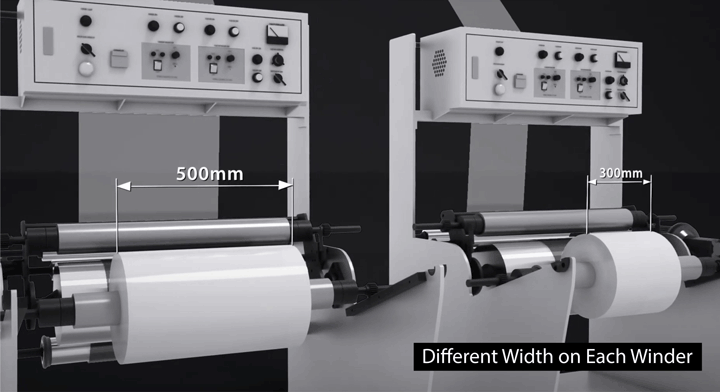

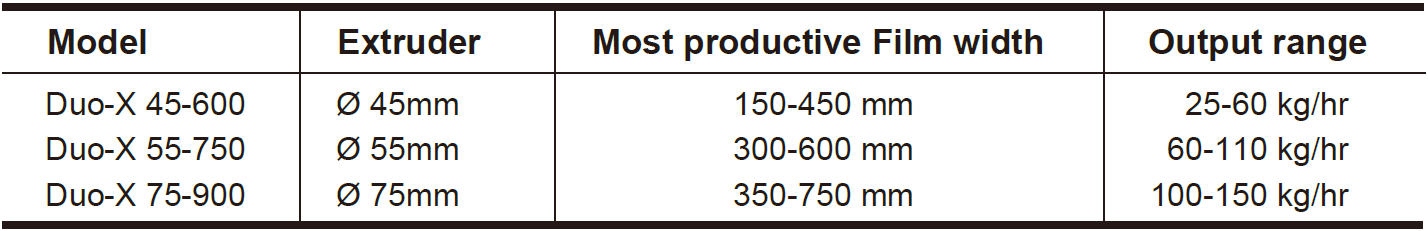

The unique design of the twin head extruder allows producers to achieve higher production especially for film ranging from 150 mm to 750mm in width, which covers the most common bag sizes in the market. The machine is highly productive for both thin HDPE film (10 micron) and thick LDPE film (100 micron).

The ability to produce different film width and thickness on each winder at the same time also adds flexibility to the production.

The ability to produce different film width and thickness on each winder at the same time also adds flexibility to the production.

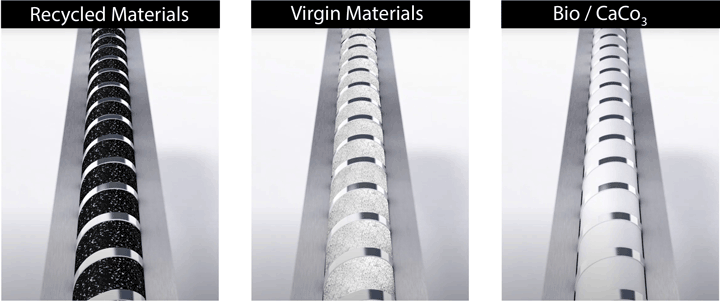

Works with Different Materials. Recycled, Virgin, CaCO3, biodegradable.

The screw design has been optimized to work with different types of materials to provide the maximum flexibility for bag producers. The screw gives very good mixing to recycled materials, color masterbatches, additives, calcium carbonate and fillers.

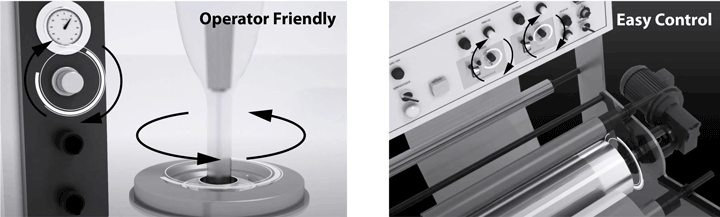

Operator-friendly Design.

The twin head blown film extruder is very simple-to-operate thanks to continuous re-designs based on customer feedbacks combined with our years of engineering experiences.

From machine start-up, operation to maintenance, we have carefully designed every detail to provide the most user-friendly experience.

From machine start-up, operation to maintenance, we have carefully designed every detail to provide the most user-friendly experience.

Every control panel is positioned at the most convenient location for operators to run the machine in a simple way.

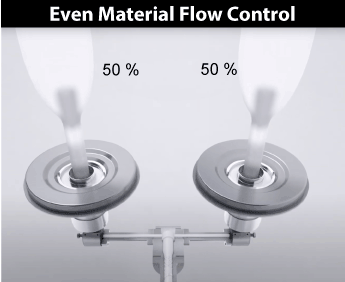

Precise Control. Stable Production.

Even Material Flow

Even Material Flow

The material going into the two die heads from the extruder is precisely-controlled, thanks to accurate temperature control throughout the entire production process. This ensures even output on both die head for stable operation.

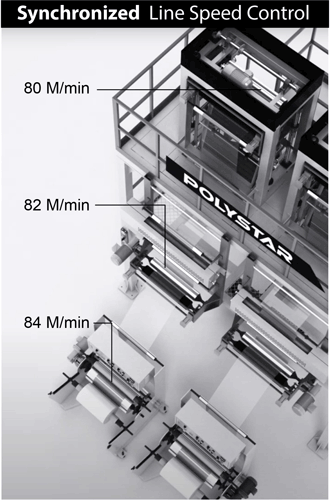

The line speed between the take-up and winding rollers are synchronized for easy machine start-up and speed/size adjustments.

The line speed between the take-up and winding rollers are synchronized for easy machine start-up and speed/size adjustments.

World-class Components.

Maximum performance. Minimum consumption.

Stable operation and low power consumption are the most important factors for plastic producers.

We have, therefore, equipped our machines with top quality electrical components and energy saving motors to minimize machine down time and energy consumption.

We have, therefore, equipped our machines with top quality electrical components and energy saving motors to minimize machine down time and energy consumption.

Fast Delivery. Simple Installation.

A standard Duo-X 55-750 can be delivered from Taiwan within 30 days

3 Popular Models

POLYSTAR Official Website

www.polystarco.com

POLYSTAR linkedin

https://www.linkedin.com/company/76949389/admin/

POLYSTAR on PRM-TAIWAN

https://www.prm-taiwan.com/com/polystar.html

www.polystarco.com

POLYSTAR linkedin

https://www.linkedin.com/company/76949389/admin/

POLYSTAR on PRM-TAIWAN

https://www.prm-taiwan.com/com/polystar.html