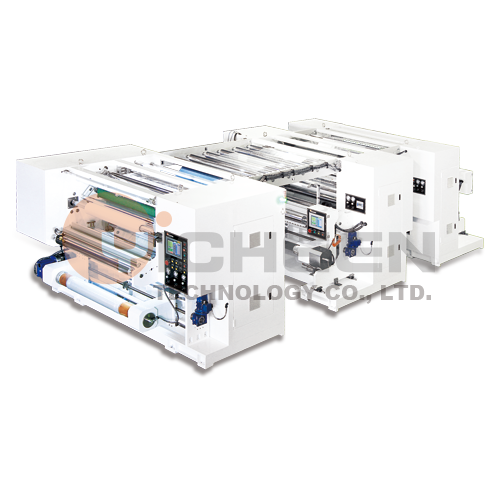

- PLC control system (M.M.I).

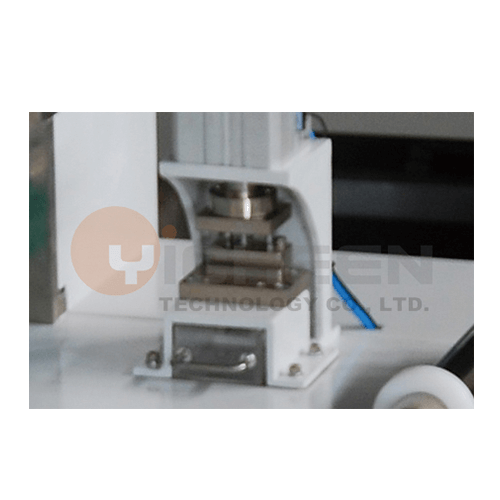

- Non-hydraulic design, no pollution, low noise, best for using in dustless room.

- Servo motor control feeding length, make sure precise cutting length.

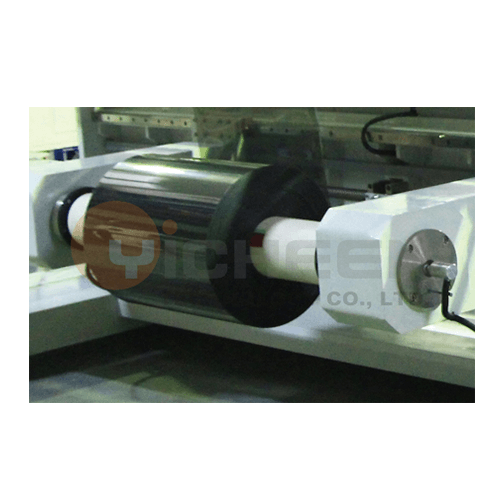

- Anti static PU roller for reducing scrape happened.

- Anti static PU roller for reducing scrape happened.

| Model | EC-740 | EC-1000 |

| Cutting width | 700mm | 950mm |

| Material thickness | 0.2~10mm | 0.2~10mm |

| Cutting length | 1~2000mm | 1~2000mm |

| Cutting speed | 70 times/min | 70 times/min |

| Cutting precision | +/-0.10mm | +/-0.10mm |

| Machine size | Approx. L800 x W1700 x H1600 mm | Approx. L1000 x W2200 x H1600 mm |

| Model | EC-1200 | EC-1400 |

| Cutting width | 1150mm | 1350mm |

| Material thickness | 0.2~10mm | 0.2~10mm |

| Cutting length | 1~2000mm | 1~2000mm |

| Cutting speed | 70 times/min | 70 times/min |

| Cutting precision | +/-0.10mm | +/-0.10mm |

| Machine size | Approx. L1100xW2440xH1600 mm | Approx. L1300xW2640xH1600 mm |

| Model | EC-1700 | EC-2700 |

| Cutting width | 1650mm | 2600mm |

| Material thickness | 0.2~10mm | 0.2~10mm |

| Cutting length | 1~2000mm | 1~2000mm |

| Cutting speed | 70 times/min | 70 times/min |

| Cutting precision | +/-0.10mm | +/-0.10mm |

| Machine size | Approx. L1300xW2940xH1600 mm | Approx. L1300xW3940xH1600 mm |

Specifications are subject to change without notice for design improvement.

The specification can be designed by customers demand.

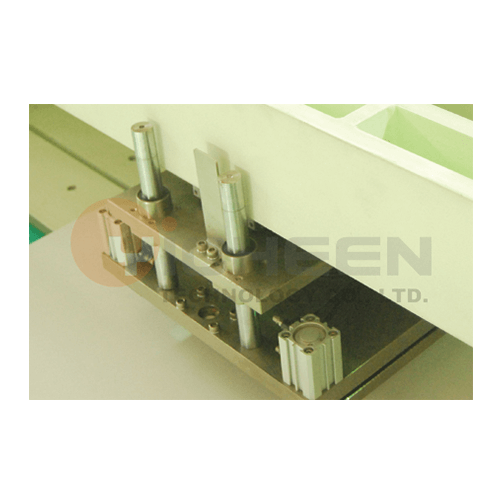

EPC, Punch hole device, Die cut device, Stacking for soft material, Shaftless device

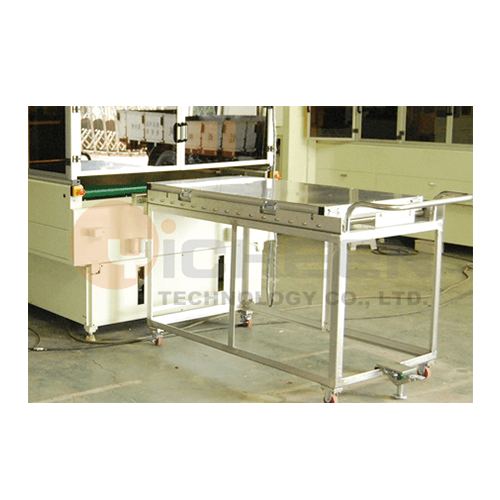

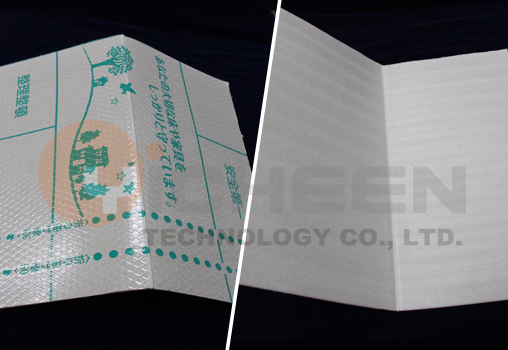

Rubber sheet, plastic sheet/films, paper and composite materials.

Model: EC

Clients: Phoenix x (Taiwan's southern plastic extrusion machine manufacturers)

Field: Plastic Extrusion Plane Plate Plan

Customer information:

1. The extrusion machine operates with a cutting line speed of 65m / min

2. The material must be placed in the centre for compression

3. Back-end stacking action.

Solution:

In order to meet the high quality requirements of Japanese customers, our factory focuses on excellent performance in cutting precision. Because of our expertise and reputation, the name Yicheen has become synonymous with precision. Despite the speed of the process, and the continuous action of our machines a certain level of cutting accuracy must be achieved. Our employees over the years, have built up a wealth of experience in order to solve these issues and reach our fully automated production goals.