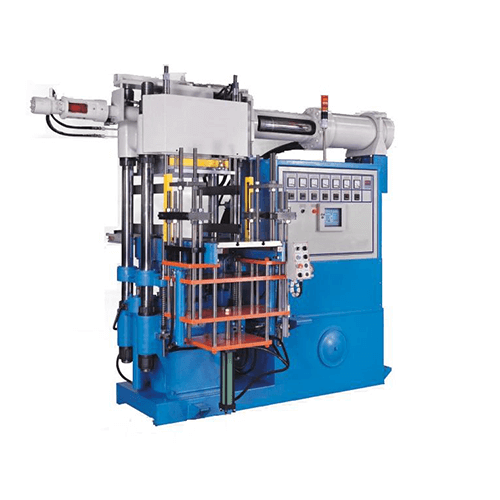

Classification : Rubber (Silicone) Injection Molding Machine

Country:

Phone: 886-37-585326

Fax: 886-37-583363

Contact Person: Jack Lin

1. Feeding system:

Specially made screw is used to achieve optimal exhaustion for the material. Heating oil is circulated to avoid jamming while increasing the feeding speed and stabilizing the temperature of the fed material.

2. Injection system:

German made resistance scale, and “cc” is used as the measuring unit. The temperature is controlled by circulating heating oil to achieve accurate injection.

3. Cold runner mechanism:

The sliding plate system is used to separate the injecting and curing function. Cold rubber compound is used for injection, and curing process is on the other plate to achieve almost zero waste material after injecting molding.

4. Monitoring design:

Full-area design to monitor the machine operation, pressure, flow rate, warning sign and warning record.

5. Hydraulic circuit design:

Proportional Pressure and flow ratio system is designed for easily changing the pressure and speed setting.

6. Electrical control system:

6-1. Precise temperature controlled is using PID calculations, temperature can be adjusted by connecting the man-machine interface.

6-2. The module saving function includes temperature, pressure/flow rate, time, injection position, ascending/descending position, and function settings.

6-3. Heating system: using SSR solid relay with fast heat-up without exceeding the limit.

6-4. Mold adjustment: slow mode adjustment function is provided. Simply to press up/down key to complete the mold position setting.

Specially made screw is used to achieve optimal exhaustion for the material. Heating oil is circulated to avoid jamming while increasing the feeding speed and stabilizing the temperature of the fed material.

2. Injection system:

German made resistance scale, and “cc” is used as the measuring unit. The temperature is controlled by circulating heating oil to achieve accurate injection.

3. Cold runner mechanism:

The sliding plate system is used to separate the injecting and curing function. Cold rubber compound is used for injection, and curing process is on the other plate to achieve almost zero waste material after injecting molding.

4. Monitoring design:

Full-area design to monitor the machine operation, pressure, flow rate, warning sign and warning record.

5. Hydraulic circuit design:

Proportional Pressure and flow ratio system is designed for easily changing the pressure and speed setting.

6. Electrical control system:

6-1. Precise temperature controlled is using PID calculations, temperature can be adjusted by connecting the man-machine interface.

6-2. The module saving function includes temperature, pressure/flow rate, time, injection position, ascending/descending position, and function settings.

6-3. Heating system: using SSR solid relay with fast heat-up without exceeding the limit.

6-4. Mold adjustment: slow mode adjustment function is provided. Simply to press up/down key to complete the mold position setting.

| TYPE | 100 TON | 200 TON | 300 TON | 400 TON 500TON |

| Stroke(mm) | 400 | 500 | 600 | 600 600 |

| Working table(mm) |

450x450

|

503x508

|

580x600

|

700x700 950x950

|

| Upper heater Plate(mm) |

450x450

|

503x508

|

580x600

|

700x700 950x950

|

| Lower heater Plater(mm) |

460x460

|

495x508

|

580x600

|

700x700 950x950

|

| Mold in-out plate(mm) | 460x500 | 490x570 | 581x660 | 704x760 959x1010 |

| Piston diameter(mm) | 250 | 350 | 450 | 500 560 |

| Inject Capacity(cc) | 1000 | 1500 | 3000 | 4000 5000 |

|

Electrical heater(KW)

|

12 | 16 | 18 | 25 35 |

| Motor(HP) | 10 | 15 | 20 | 20 25 |

| Total power(KW) |

19.5

|

27

|

33

|

40 68

|

| Size |

|

|

|

|

| Mold opening Method |

0RT: Ascending/Descending |

|||

| 1RT: Sliding mold In / out | ||||

|

2RT: Front ejector for

upper mold plate

3RT: Front ejector for upper and middle mold plate 4RT: 3RT with a hydraulic cylinder at the bottom |

||||