| Model | International Size | Theoretical Injection Volume | Clamping Force | Space Between Tie Bars | Mould Opening Stroke |

| Servo 90E | 900H-326 | 183 | 90 | 360x360 | 330 |

| Servo 120E | 1200H-435 | 251 | 120 | 395x395 | 380 |

| Servo 150E | 1500H-614 | 366 | 150 | 425x425 | 430 |

| Servo 190E | 1900H-760 | 491 | 190 | 470x470 | 480 |

| Servo 230E | 2300H-958 | 641 | 230 | 515x515 | 525 |

| Servo 270E | 2700H-1423 | 848 | 270 | 555x555 | 570 |

| Servo 320E | 3200H-1703 | 1062 | 320 | 620x620 | 620 |

| Servo 370E | 3700H-2045 | 1308 | 370 | 700x650 | 670 |

| Servo 470E | 4700H-2862 | 1910 | 470 | 770x742 | 770 |

| Servo 570E | 5700H-4462 | 3083 | 570 | 860x800 | 860 |

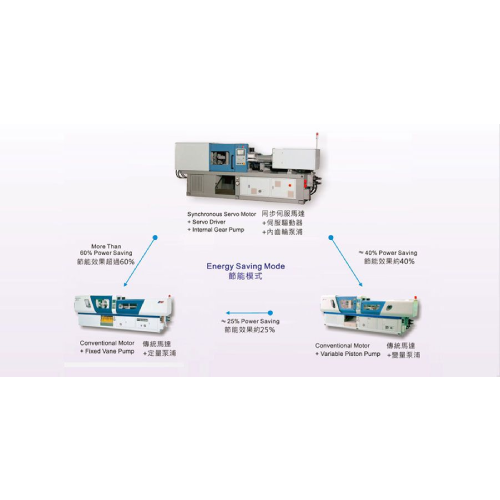

SAVING ENERGY = SAVE OUR EARTH

According to various setups of molding terms, Servo E consumes 40% less energy than the machine with a variable displacement pump or inverter, and averagely 60% less compared to the machine with a fixed displacement pump.

LESS VOLUME OF OIL & COOLING WATER CONSUMED

Servo E has no issues of oil heat generation caused by the flow relief valve in the IMM with a fixed pump, or oil draining by the IMM with a variable pump, so a smaller capacity of heat exchange and less volume of cooling water are required. The oil consumption is cut in half so, the oil storage and the cost of refilling are lower. The standard hydraulic design of the logic circuit shortens the response moment of the hydraulics and achieves pressure/speed control precisely.