Country: Taiwan

Phone: +886-6-5950688 (6879)

Fax: +886-6-5951129

Contact Person: Hank Wu, Manager

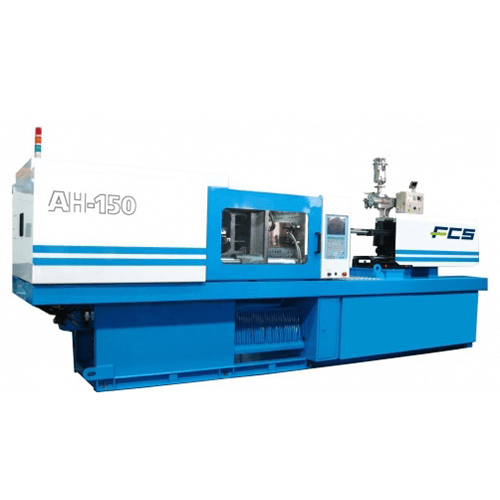

High injection speed and response:

‧ The new single injection cylinder design achieves synchronization which is more excellent than dual design, and helpful to improve injection stability and suitable for high speed injection molding.

‧ Framework design feature is that the hydraulic motor is mounted on the framework and not moves with the reciprocating injection screw. This reduces the inertia and promotes the response (70ms) and stability in injection molding.

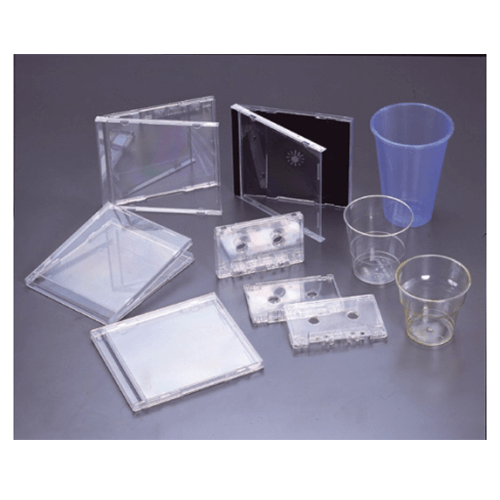

‧ High speed injection molding reduce injection time and increase the shear heat of plastic to help the integrity which hotly fills in the thin-wall food containers.

‧ With high responding accumulator, the maximum injection speed rate is up to 300 mm/sec that can achieve the duty of molding thin-wall containers.

High repeatability and stability

‧ AH Series adopt Vickers high response close-loop servo valve for maintaining its repeatability and controlling the holding pressure.

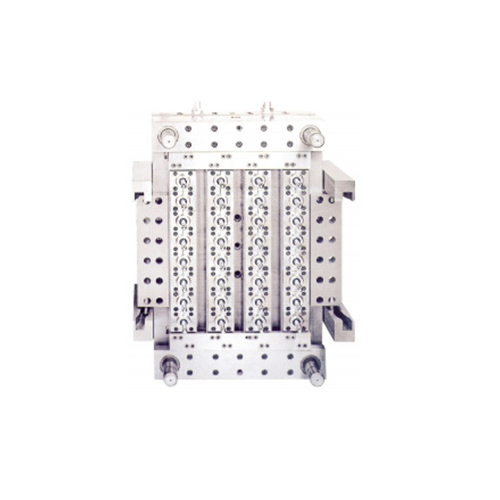

High rigidity and durability structure

‧ Enhance the rigidity of clamping system, reduce structure deformation and force uniformity to fill the needs of high speed injection machine.

‧ Guarantee the mold parallelism in the molding process.

Optimization of toggle mechanism dimension

‧ The optimal toggle mechanism dimension is calculated by Genetic Algorithms method

‧ Smooth motion of mold open and close, and increase speed by 20%.

‧ Reduces the toggle loading and bushing abrasion.

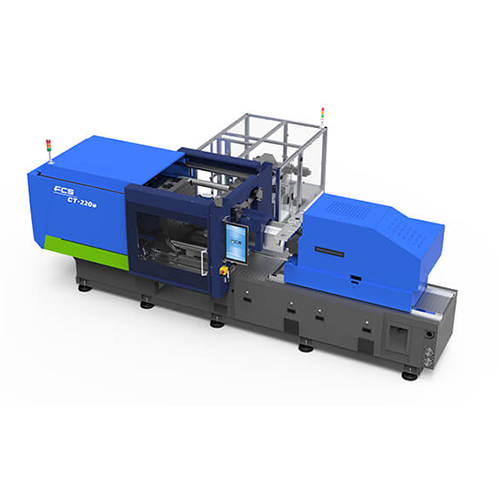

‧ The new single injection cylinder design achieves synchronization which is more excellent than dual design, and helpful to improve injection stability and suitable for high speed injection molding.

‧ Framework design feature is that the hydraulic motor is mounted on the framework and not moves with the reciprocating injection screw. This reduces the inertia and promotes the response (70ms) and stability in injection molding.

‧ High speed injection molding reduce injection time and increase the shear heat of plastic to help the integrity which hotly fills in the thin-wall food containers.

‧ With high responding accumulator, the maximum injection speed rate is up to 300 mm/sec that can achieve the duty of molding thin-wall containers.

High repeatability and stability

‧ AH Series adopt Vickers high response close-loop servo valve for maintaining its repeatability and controlling the holding pressure.

High rigidity and durability structure

‧ Enhance the rigidity of clamping system, reduce structure deformation and force uniformity to fill the needs of high speed injection machine.

‧ Guarantee the mold parallelism in the molding process.

Optimization of toggle mechanism dimension

‧ The optimal toggle mechanism dimension is calculated by Genetic Algorithms method

‧ Smooth motion of mold open and close, and increase speed by 20%.

‧ Reduces the toggle loading and bushing abrasion.

The following specifications are for your reference only and can not be used as the machine acceptance criteria. Please contact with our sales representatives to confirm the most appropriate machine features.

The features are for your reference only. Due to continuous improvements, we reserve the right to amend any of the above

specifications without prior notice.

The features are for your reference only. Due to continuous improvements, we reserve the right to amend any of the above

specifications without prior notice.