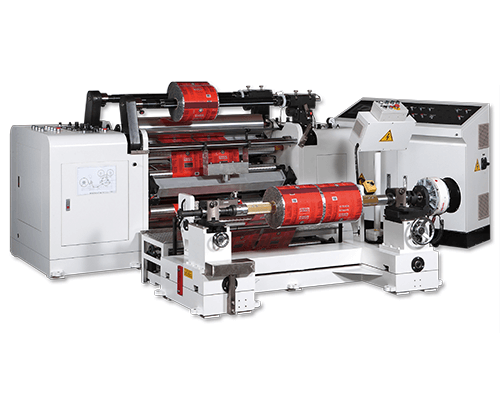

Classification : Slitting Machine

Country: Taiwan

Phone: 886-4-24832477

Fax: 886-4-24830852

Contact Person: Angela Chi

Materials

- Laminated films 40-150μ; OPP 30-150μ; CPP 30-150μ; PVC (Soft), 30-150μ; PET 30-80μ.

- Diff erential center rewinding with duplex rewind shafts.

- Shaft less unwinding stand (Motorised left / right movement) with mechanical chuck.

- Equipped with digital type line position control (LPC) to ensure accurate slitting position.

- Equipped with razor cutter and cutting in the air.

- Equipped with grooved roller for razor blades.

- Equipped with blower and expulsion tube.

- Cantilevered type mechanical rewinding shafts for easy operation.

- Equipped with ball type friction rings, which not only can facilitate the concentricity of the paper cores and finish rolls, but also can make unloading easier without causing paper dust.

- Equipped with automatic tension controlling system and load-cells. The actual tension is digitally displayed, increasing the tension control precision with minimal operation e ffort.

- Static eliminated brush equipped.

- Lay-on roller pneumatic pressure control system.

- Unloading device.

| Model No. | SLF-MB200 | |

| MAX. PARENT WEB WIDTH | 500~2000mm | |

| MAX. PARENT WEB DIAMETER | 500/ 650/ 800/1000mm | |

| THICKNESS RANGE | Depends on various materials’ conditions | |

| MAX. REWIND DIAMETER | 420/600/800mm | |

| MIN. SLIT WIDTH | 20mm(Depends on various materials' conditions) | |

| UNWIND/REWIND CORE I.D. | 3" (Or as request) | |

| MAX. MACHINE SPEED | 200/300M/min. | |

|

INSTALLATION INFORMATION (For 1000mm standard machine) |

NET WEIGHT | 3000kg |

| AREA REQUIRED | L2200xW3300XH1405 | |

| POWER | As request | |

| AIR | 6kg/cm 3 | |

| APPLICATION & MATERIALS |

|

| REWINDING TYPE |

|

| UNWINDING SECTION |

|

| UNWINDING TENSION CONTROL |

|

| SLITTING SECTION |

|

| REWINDING SECTION |

|

| REWINDING TENSION CONTROL |

|

| TRIMMED WASTE |

|

| OPTIONAL ACCESSORIES |

|